A 580MPa grade aluminum alloy drill pipe body and its manufacturing method

A 580mpa, aluminum alloy technology, used in the field of oil well pipe manufacturing, can solve problems such as insufficient strength of pipes, and achieve the effects of improving strength and repeated loading resistance, improving thermal strength, and improving high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

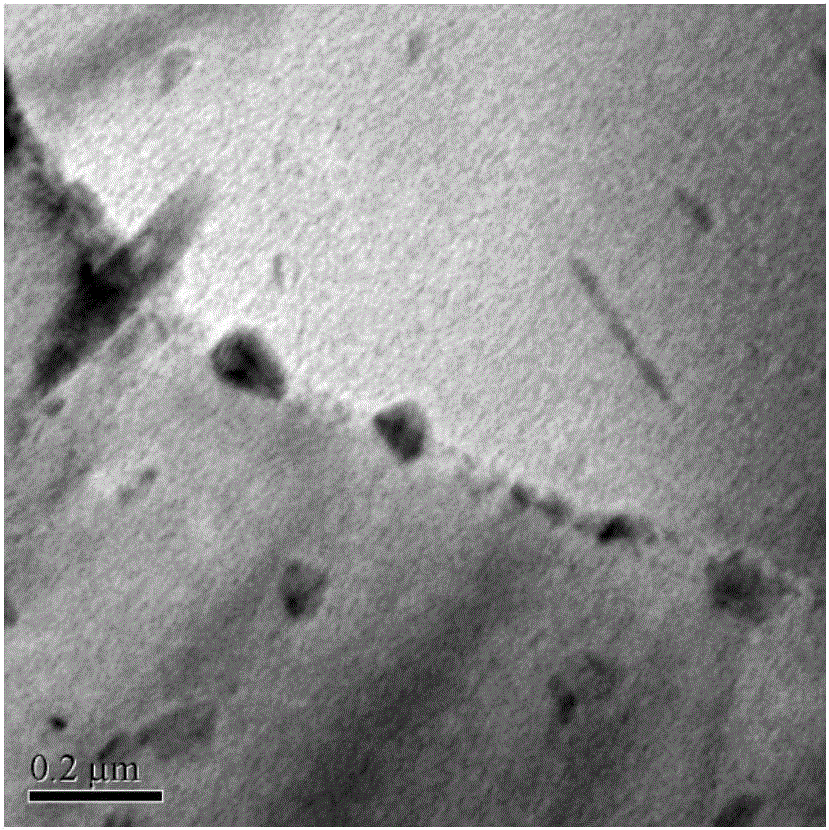

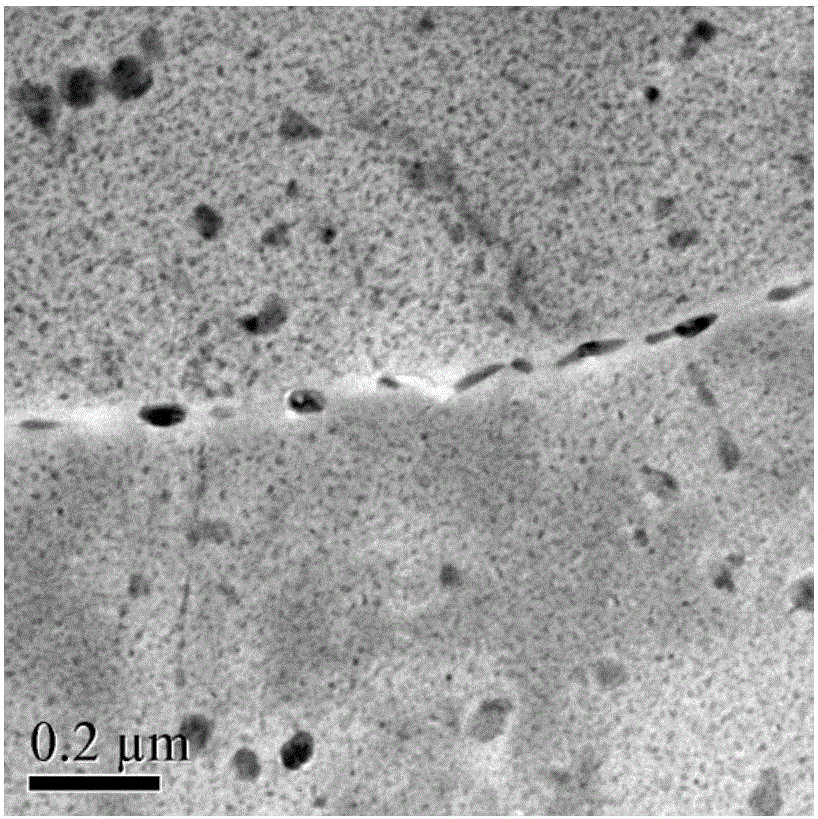

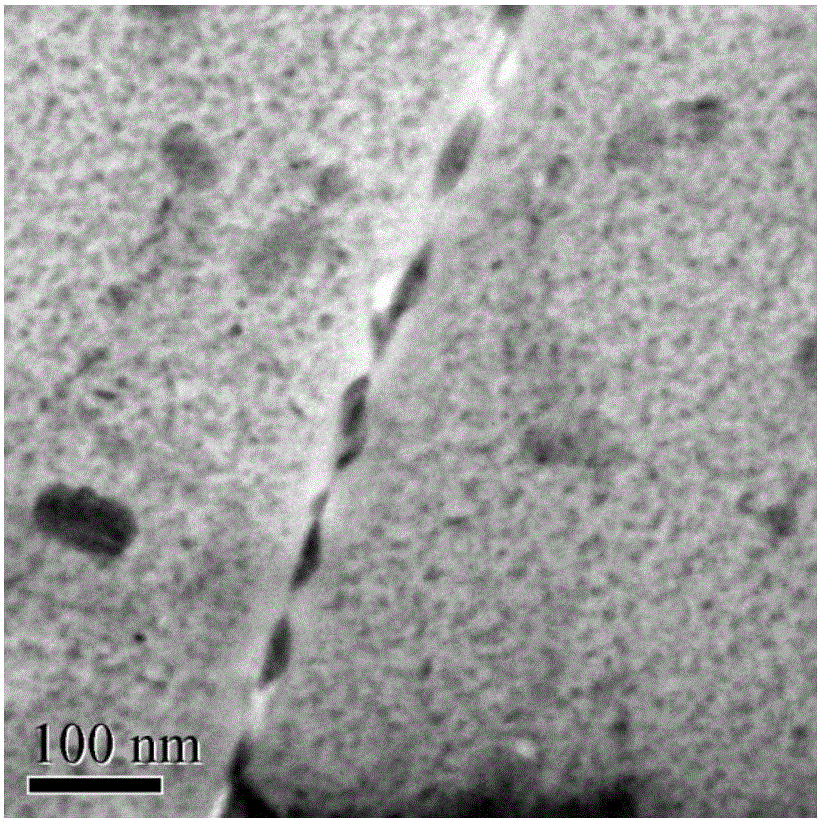

Image

Examples

Embodiment 1

[0037] The chemical composition of the 580MPa aluminum alloy drill pipe body is by weight percentage: Zn 6.3%, Mg 2.1%, Cu 2.3%, Fe 0.3%, Ni 0.3%, Zr 0.2%, Ti 0.02%, the balance For Al and unavoidable impurities.

[0038]The preparation method of the pipe body for 580MPa grade aluminum alloy drill pipe, the above raw materials are smelted and cast to obtain the tube blank, and under the condition of heating rate of 10°C / min, the tube blank is subjected to 380°C×8h+420°C×12h+460°C× Homogenize for 32 hours, cool down to room temperature naturally, then hold at 420°C for 20 minutes, then extrude and deform, the extrusion ratio is greater than 18, and the extrusion speed is 3mm / s; then it is solid solution quenched at 455°C×2h+470°C×1h After treatment, spray water to cool, cool to room temperature at a cooling rate of 30°C / s, and then apply 2% pre-stretch deformation to the pipe body after solution quenching, and then perform artificial aging treatment at 120°C for 36h.

[0039] ...

Embodiment 2

[0041] The chemical composition of the 580MPa grade aluminum alloy drill pipe body is by weight percentage: Zn 6.8%, Mg 2.2%, Cu 2.5%, Fe 0.3%, Ni 0.2%, Zr 0.2%, Ti 0.02%, the balance For Al and unavoidable impurities.

[0042] The preparation method of the pipe body for 580MPa grade aluminum alloy drill pipe, the above raw materials are smelted and cast to obtain the tube blank, and under the condition of heating rate of 10°C / min, the tube blank is subjected to 380°C×8h+420°C×12h+460°C× Homogenize for 32 hours, cool down to room temperature naturally, then hold at 420°C for 20 minutes, then extrude and deform, the extrusion ratio is greater than 18, and the extrusion speed is 3mm / s; then it is solid solution quenched at 455°C×2h+470°C×1h After treatment, spray water to cool, cool to room temperature at a cooling rate of 30°C / s, and then apply 2% pre-stretch deformation to the pipe body after solution quenching, and then perform artificial aging treatment at 120°C for 12h.

...

Embodiment 3

[0045] The chemical composition of the 580MPa grade aluminum alloy drill pipe body is by weight percentage: Zn 7.3%, Mg 2.3%, Cu 2.3%, Fe 0.3%, Ni 0.3%, Zr 0.2%, Ti 0.02%, the balance For Al and unavoidable impurities.

[0046] The preparation method of the pipe body for 580MPa grade aluminum alloy drill pipe, the above raw materials are smelted and cast to obtain the tube blank, and under the condition of heating rate of 10°C / min, the tube blank is subjected to 380°C×8h+420°C×12h+460°C× Homogenize for 32 hours, cool down to room temperature naturally, then hold at 420°C for 20 minutes, then extrude and deform, the extrusion ratio is greater than 18, and the extrusion speed is 3mm / s; then it is solid solution quenched at 455°C×2h+470°C×1h After treatment, spray water to cool, cool to room temperature at a cooling rate of 30°C / s, and then apply 2% pre-stretch deformation to the pipe body after solution quenching, and then perform artificial aging treatment at 120°C for 48h.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com