A kind of high-toughness nb-doped w/tic composite material and preparation method thereof

A composite material and high toughness technology, applied in the field of high toughness Nb-doped W/TiC composite material and its preparation, can solve the problems of reducing the plastic toughness, recrystallization brittleness, and irradiation brittleness of tungsten-based materials, and achieve the improvement of grain boundary Effects of binding force, improving toughness, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

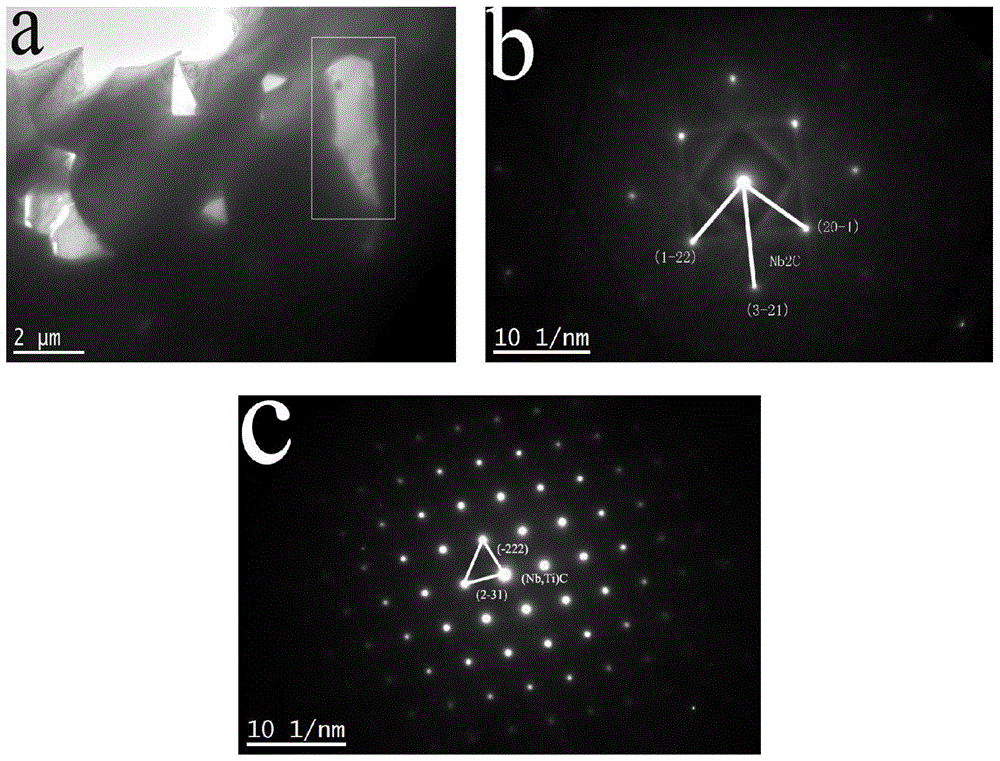

Image

Examples

Embodiment 1

[0015] 1. Preparation of composite powder

[0016] According to the ratio of W-1.5wt%Nb-1wt%TiC, add a total of 22.5g of W powder, Nb powder and TiC powder into the ball mill tank for ball milling for 4 hours, the ball-to-material ratio is 20:1, and the speed is 400r / min. Obtain composite powder.

[0017] 2. Sintering of composite materials

[0018] The composite powder was pressed at a pressure of 300MPa to obtain a compact, and the compact was sintered in a high-temperature sintering furnace. During the sintering process, Ar was used as a protective gas, kept at 2200°C for 2h, cooled to 1000°C and then cooled to At room temperature, the Nb-doped W / TiC composite material is obtained. During the sintering process, the heating rate was 5°C / min, and the cooling rate was 5°C / min. The thermal shock energy of the composite material obtained after sintering at 700°C is 116.6KJ / m 2 .

Embodiment 2

[0020] 1. Preparation of composite powder

[0021] According to the ratio of W-3wt%Nb-1wt%TiC, a total of 25g of W powder, Nb powder and TiC powder were added to the ball mill tank for ball milling for 4 hours, the ball-to-material ratio was 20:1, and the speed was 400r / min to obtain a composite Powder.

[0022] 2. Sintering of composite materials

[0023] Press the composite powder with a unit pressure of 300MPa to obtain a green compact, put the green compact into a high-temperature sintering furnace for sintering, use Ar as a protective gas during the sintering process, keep it at 2200°C for 2 hours, cool down with the furnace after cooling down to 1000°C to room temperature, the Nb-doped W / TiC composite material is obtained. During the sintering process, the heating rate was 5°C / min, and the cooling rate was 5°C / min. The thermal shock energy of the composite material obtained after sintering at 700°C is 80.9KJ / m2.

Embodiment 3

[0025] 1. Preparation of composite powder

[0026] According to the ratio of W-1wt%Nb-1wt%TiC, a total of 28g of W powder, Nb powder and TiC powder were added to the ball mill pot for ball milling for 4h, the ball-to-material ratio was 20:1, and the speed was 400r / min to obtain a composite Powder.

[0027] 2. Sintering of composite materials

[0028] The composite powder is pressed at a unit pressure of 300MPa to obtain a green compact, and the green compact is sintered in a high-temperature sintering furnace. During the sintering process, Ar is used as a protective gas, and it is kept at 2200°C for 2 hours. After cooling down to 1000°C, it is cooled with the furnace. to room temperature, the Nb-doped W / TiC composite material is obtained. During the sintering process, the heating rate was 5°C / min, and the cooling rate was 5°C / min. The thermal shock energy of the composite material obtained after sintering at 700°C is 75.4KJ / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com