Nano-porous material prepared through selective corrosion of Zr-Ti-Cu alloy and preparation method thereof

A zr-ti-cu, nano-porous technology, applied in the field of nano-materials, can solve problems such as the difficulty in preparing nano-porous materials with uniform pore size, and achieve the effect of good mechanical integrity and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Select Cu 5 Zr 25 Ti 25 As the target alloy, the atomic ratio (at.%) of Ti, Zr, and Cu is 25:25:50, and it is converted into mass percentage to accurately and accurately weigh pure Ti (99.99%), pure Zr (99.99%) %) and pure Cu (99.99%), put the configured metal into WKI series non-consumable vacuum melting under the protection of high-purity argon (purity: 99.999%) to obtain a master alloy ingot with uniform composition.

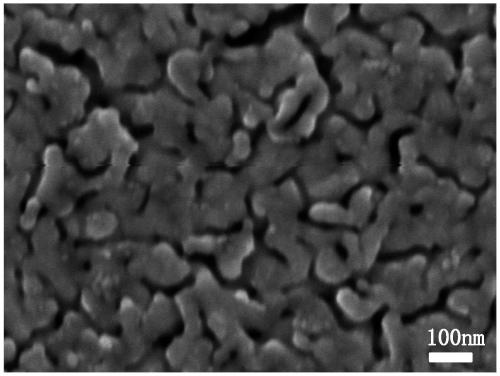

[0031] After putting the crushed master alloy into ultrasonic cleaning, take 3g of master alloy and place it in a quartz tube with a bottom opening of 1 mm, and pump the vacuum shaker to a high vacuum (3.0×10 -3 Pa) after being filled with high-purity argon protection, when the induction current is added to 18A, the master alloy is completely melted, and the molten alloy is sprayed onto a high-speed rotating (3500r / min) copper roller under a pressure difference of 0.02MPa. An amorphous ribbon with a thickness of 20 μm and a width of 1.2 μm was obtai...

Embodiment 2

[0034] Select Cu 50 Zr 25 Ti 25 As the target alloy, the atomic ratio (at.%) of Ti, Zr, and Cu is 25:25:50, and it is converted into mass percentage to accurately and accurately weigh pure Ti (99.99%), pure Zr (99.99%) %) and pure Cu (99.99%), put the configured metal into WKI series non-consumable vacuum melting under the protection of high-purity argon (purity: 99.999%) to obtain a master alloy ingot with uniform composition.

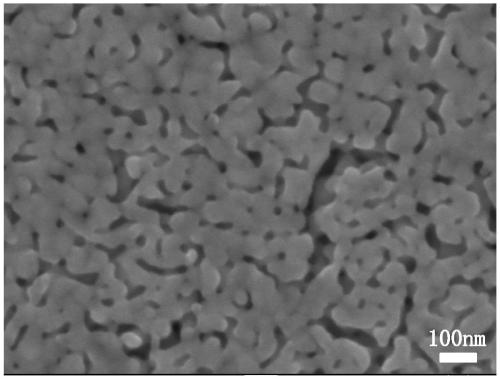

[0035] After putting the crushed master alloy into ultrasonic cleaning, take 3g of master alloy and place it in a quartz tube with a bottom opening of 1 mm, and pump the vacuum shaker to a high vacuum (3.0×10 -3 Pa) after being filled with high-purity argon protection, when the induction current is added to 18A, the master alloy is completely melted, and the molten alloy is sprayed onto a high-speed rotating (3500r / min) copper roller under a pressure difference of 0.02MPa. An amorphous ribbon with a thickness of 20 μm and a width of 1.2 μm was obta...

Embodiment 3

[0038] Select Cu 50 Zr 25 Ti 25As the target alloy, the atomic ratio (at.%) of Ti, Zr, and Cu is 25:25:50, and it is converted into mass percentage to accurately and accurately weigh pure Ti (99.99%), pure Zr (99.99%) %) and pure Cu (99.99%), put the configured metal into WKI series non-consumable vacuum melting under the protection of high-purity argon (purity: 99.999%) to obtain a master alloy ingot with uniform composition.

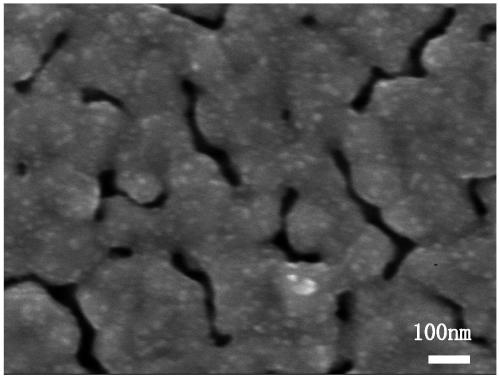

[0039] After putting the crushed master alloy into ultrasonic cleaning, take 3g of master alloy and place it in a quartz tube with an opening of about 1 mm at the bottom end, and pump the vacuum shaker to a high vacuum (3.0×10 -3 Pa) back filled with high-purity argon protection, when the induction current is added to 18A, the master alloy is completely melted, and the molten alloy is sprayed onto the high-speed rotating (3500r / min) copper roller at a pressure difference of about 0.02MPa, A thin amorphous ribbon having a thickness of 20 μm and a wid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com