Volatile organic chemicals (VOCs) recovery system based on liquefied natural gas (LNG) cold energy

A recovery system and cold energy technology, applied in pipeline systems, container discharge methods, and equipment discharged from non-pressure containers, etc., can solve problems such as affecting normal supply and VOCs emissions failing to meet requirements, and reduce equipment investment. Cost, Emission Reduction, and Recovery Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

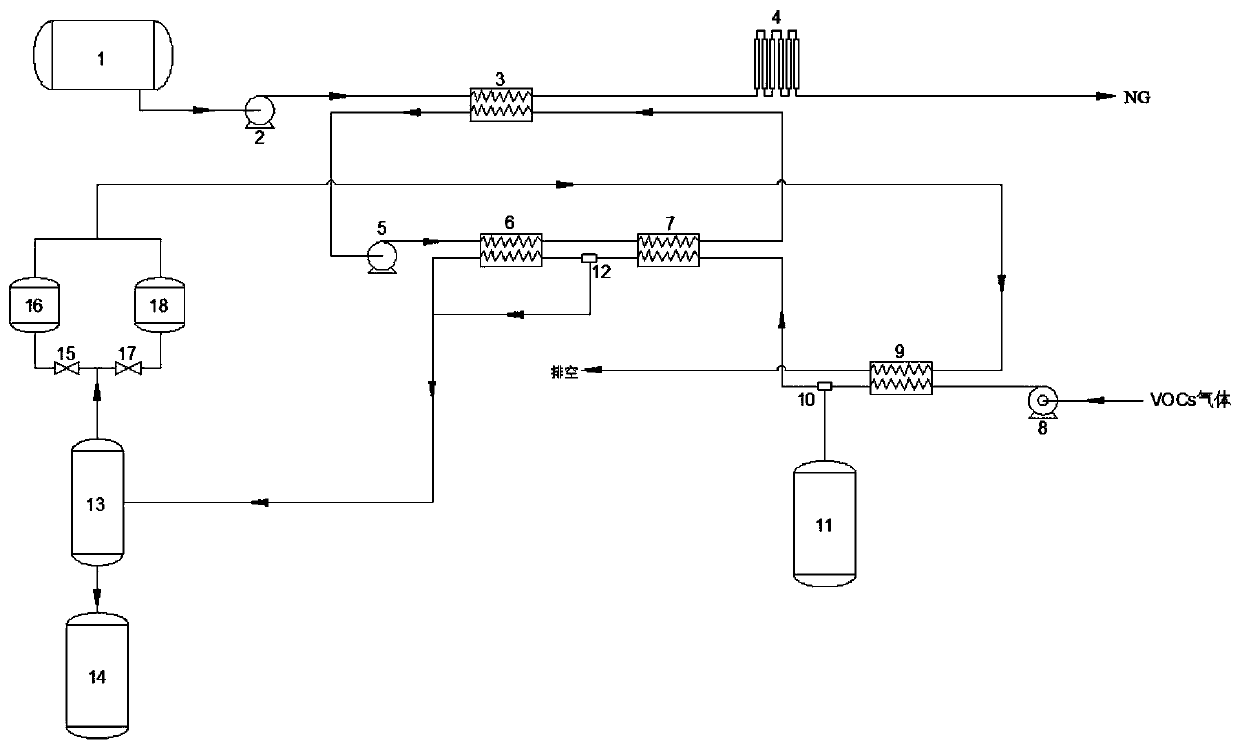

[0027] Such as figure 1 As shown, a VOCs recovery system based on LNG cold energy, including LNG cold energy supply system, VOCs condensation recovery system and VOCs adsorption purification system,

[0028] In this example, the VOCs gas concentration from the production link is 50g / m 3 , the temperature is 40°C, and the type is mixed aromatic hydrocarbons.

[0029] In the LNG cold energy supply system, after the LNG from the LNG storage tank (1) is pressurized by the LNG booster pump (2), it is vaporized into NG in the LNG heat exchanger (3), and the cold energy is transferred to VOCs condenses the R22 in the recovery system, the temperature of NG rises to -130°C, and then the temperature of NG rises to 25°C in the air-temperature vaporizer (4). After the R22 is cooled to -120°C in the LNG heat exchanger (3), after being pressurized by the refrigerant circulation pump (5), it enters the VOCs deep cooler (6) and the VOCs primary cooler (7) successively to release cold energy...

Embodiment 2

[0033] In this example, the VOCs gas temperature from the production link is consistent with the type and embodiment 1, and the concentration rises to 100g / m 3 .

[0034] In the LNG cold energy supply system, LNG is vaporized into NG in the LNG heat exchanger (3), and the cold energy is transferred to R22 in the VOCs condensation recovery system. Warming up to 25°C in the carburetor (4). After the R22 is cooled to -120°C in the LNG heat exchanger (3), it enters the VOCs cryocooler (6) and the VOCs primary cooler (7) in turn to condense the liquefied VOCs gas, and the VOCs cryocooler (6) exits The temperature of R22 rises to -113°C, and the temperature of R22 rises to -68°C at the outlet of the VOCs primary cooler (7).

[0035] In the VOCs condensation recovery system, the VOCs gas is cooled to -5°C in the VOCs dehydrator (9), the water vapor in the VOCs gas is removed, and the condensed water is discharged into the collector in the first pipeline separator (10). Water tank ...

Embodiment 3

[0038] In this example, the VOCs gas temperature from the production link is consistent with the type and embodiment 1, and the concentration rises to 150g / m 3 .

[0039] In the LNG cold energy supply system, LNG is vaporized into NG in the LNG heat exchanger (3), and the cold energy is transferred to R22 in the VOCs condensation recovery system. Warming up to 25°C in the carburetor (4). After the R22 is cooled to -120°C in the LNG heat exchanger (3), it enters the VOCs cryocooler (6) and the VOCs primary cooler (7) in turn to condense the liquefied VOCs gas, and the VOCs cryocooler (6) exits The temperature of R22 rises to -110°C, and the temperature of R22 rises to -65°C at the outlet of the VOCs primary cooler (7).

[0040] In the VOCs condensation recovery system, the VOCs gas is cooled to -5°C in the VOCs dehydrator (9), the water vapor in the VOCs gas is removed, and the condensed water is discharged into the collector in the first pipeline separator (10). Water tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com