High-sensitivity temperature measurement method and application based on bismuth-manganese co-doped dual luminescence properties

A technology with high sensitivity and luminescence characteristics, applied in the field of temperature sensing, which can solve problems such as energy level difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

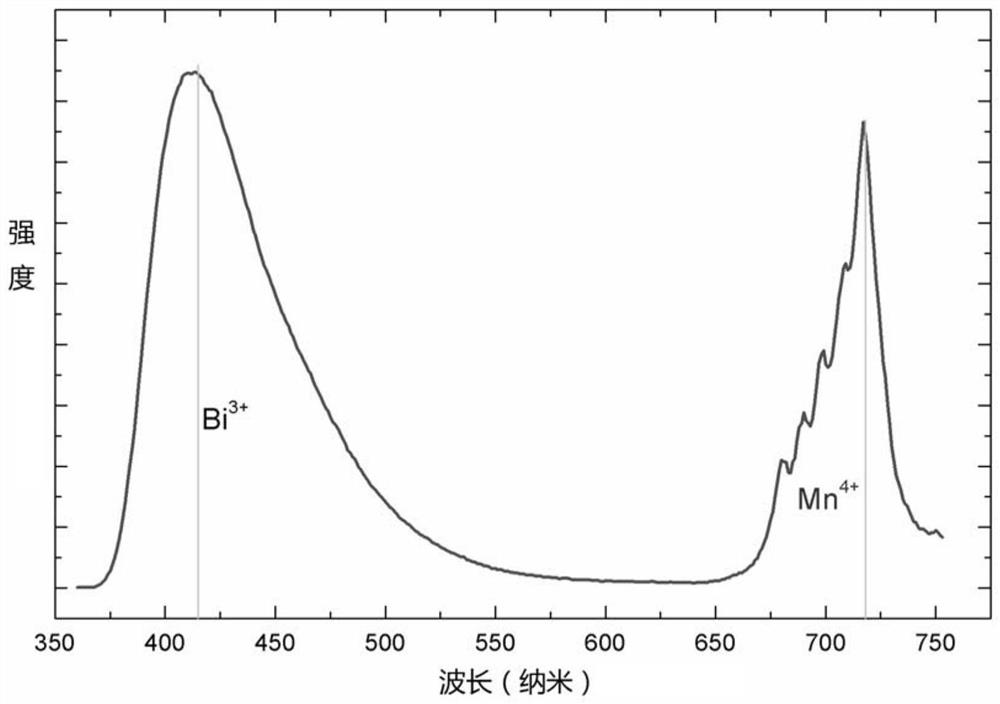

[0047] 1. Co-doping bismuth and manganese into inorganic oxides at a reasonable concentration to prepare a fluorescent temperature sensing material that emits light together with trivalent bismuth and tetravalent manganese;

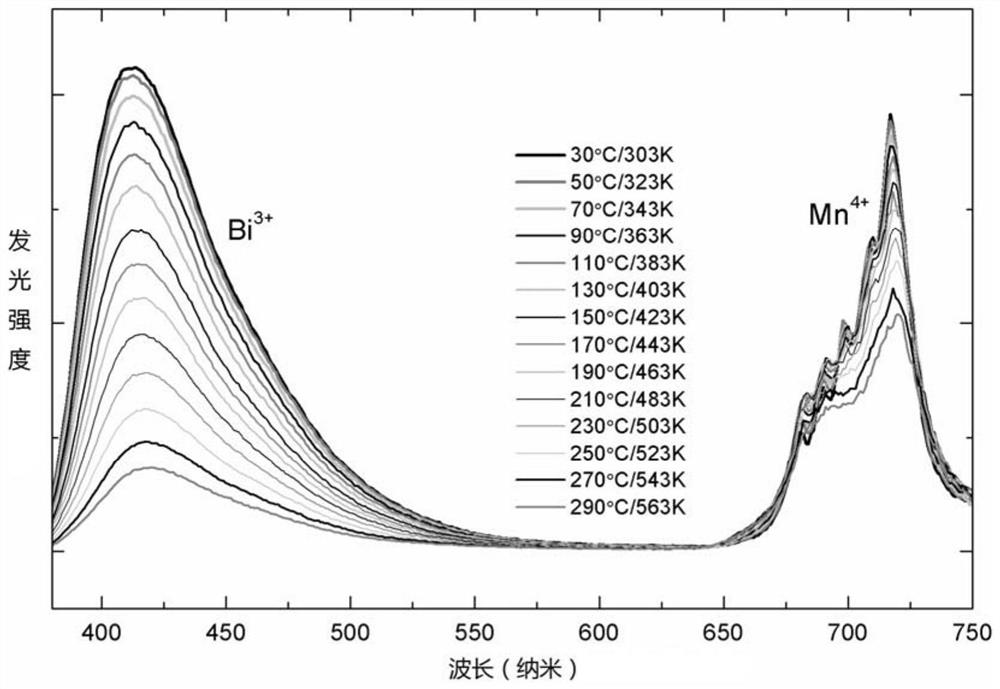

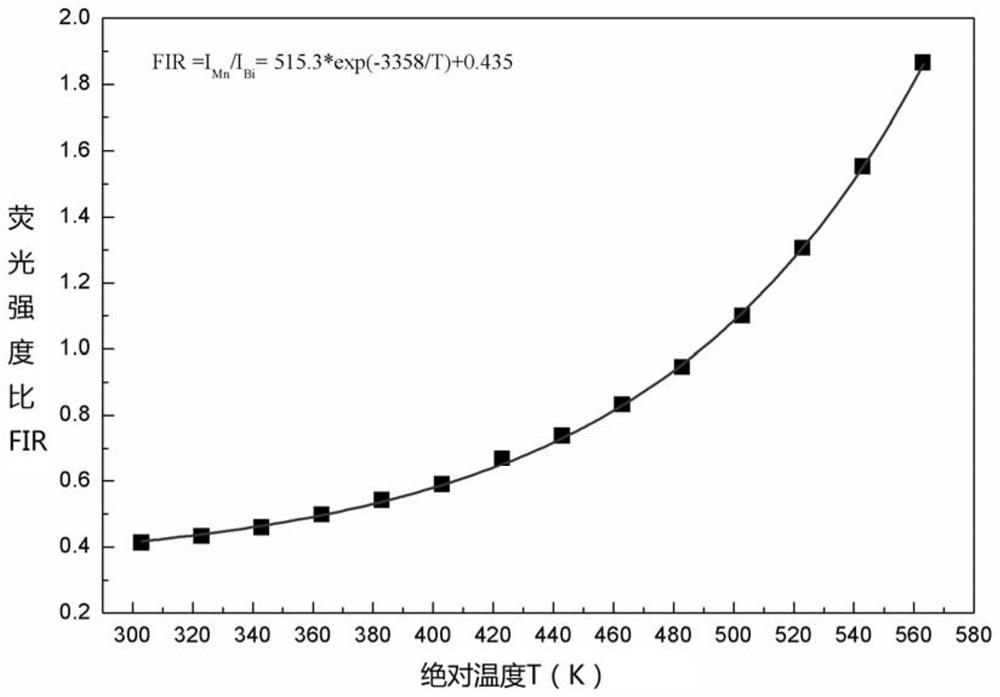

[0048] 2. Test the emission spectrum of the fluorescent temperature sensing material at different temperatures, and establish a standard working curve for the characteristic emission peak intensity ratio of trivalent bismuth and tetravalent manganese as the ambient temperature changes;

[0049] 3. Place the fluorescent temperature sensing material in the environment of the temperature to be measured, measure the emission spectrum of the fluorescent temperature sensing material, and then obtain the emission peak intensity ratio of trivalent bismuth and tetravalent manganese;

[0050] 4. Substituting the ratio into the standard working curve in step 2 to obtain the temperature measurement value of the environment to be measured, and complete the high-sensiti...

Embodiment 2

[0062] The difference between this embodiment and the previous embodiment is that the fluorescent temperature sensing material prepared in step 1 has a specific atomic ratio composition: (Ca 1.995 Sr)(Al 2.99 Ga)ZnO 10 : Bi 0.005 3+ ,Mn 0.01 4+ . Other steps and parameters are the same as those in the previous embodiment.

Embodiment 3

[0064] The difference between this embodiment and the previous embodiment is that the preparation method of the fluorescent temperature sensing material in step 1 is to dissolve the corresponding nitrates of Ca, Sr, Al, Ga, Zn, Bi, Mn according to the atomic ratio under the condition of stirring. A mixed solution was obtained in deionized water, and then citric acid was added to the mixed solution, and then dried at 90°C to form a gel, and then sintered step by step at 500°C and 1200°C for 4 hours each to obtain a sample. Other steps and parameters are the same as those in the previous embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com