An all-in-one machine suitable for rock true triaxial, dry-wet cycle and acoustic emission tests

A dry-wet cycle, acoustic emission technology, applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, measuring devices, etc., can solve the problem of reducing the number and energy of acoustic emission events, increasing the propagation distance, and low information signal-to-noise ratio. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

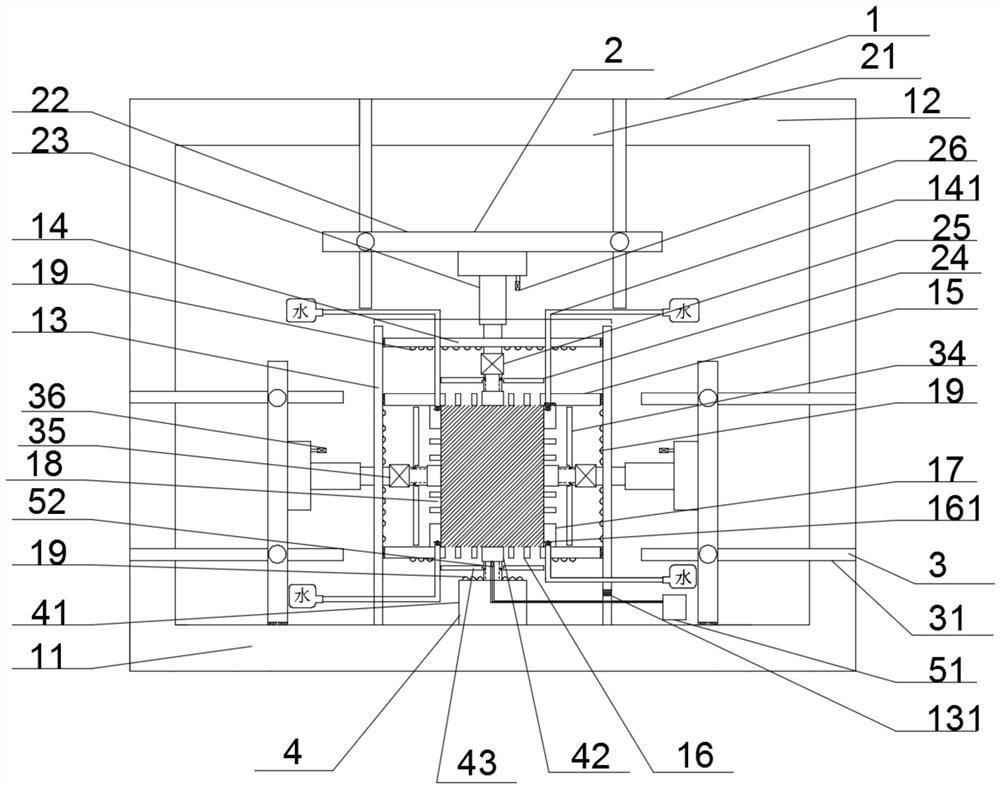

[0011] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

[0012] Please refer to figure 1 , figure 2 , which is a schematic diagram of an integrated machine suitable for true triaxial rock, dry-wet cycle and acoustic emission test provided by the present invention.

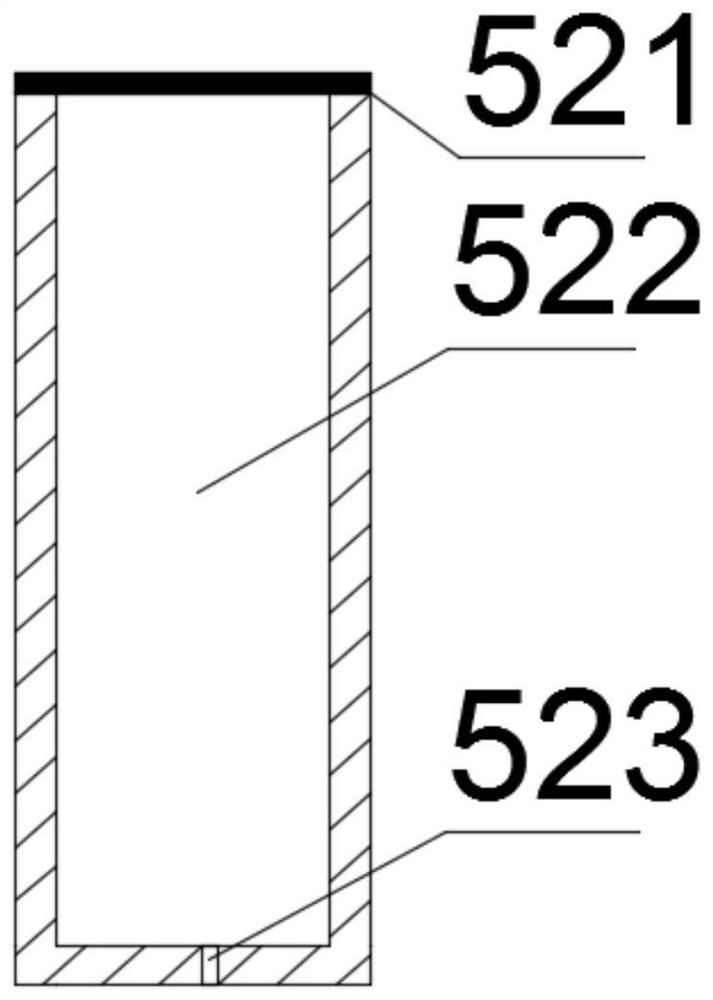

[0013] The integrated machine for rock true triaxial, dry-wet cycle and acoustic emission testing includes: test accommodating mechanism 1, top lifting mechanism 2, lateral telescopic mechanism 3, bottom lifting mechanism 4, and acoustic emission mechanism 5. The mounting mechanism 1, the upper telescopic mechanism 2, the left telescopic mechanism 3, and the right telescopic mechanism 4 are arranged on the test accommodating mechanism 1, and the acoustic emission mechanism 3 is arranged on the test accommodating mechanism 1 sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com