Proportional electromagnet

A proportional electromagnet and armature technology, which is applied in the field of low-speed diesel engine high-pressure common rail system components, can solve problems affecting the performance of the common rail fuel system, emissions, difficulty in ensuring the coaxiality of the inner hole of the guide sleeve, and affecting the size of the fuel injection. Achieve the effects of improving coaxiality and reliability, avoiding loose plugs, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further illustrate the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

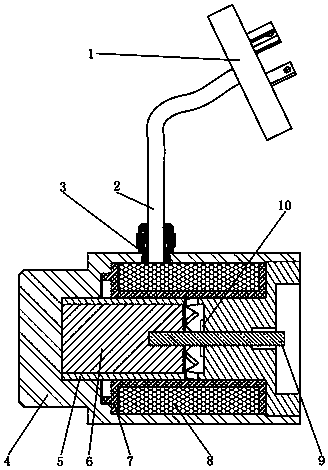

[0025] see figure 1 As shown, the proportional electromagnet for low-speed machines mainly includes a plug 1 , a casing 4 , a guide sleeve 5 , an armature 6 and a coil 8 .

[0026] The guide sleeve 5 is installed in the cavity of the housing, and the coil 8 is wound between the housing 4 and the guide sleeve 5 , the armature 6 is installed in the guide sleeve, and the front end of the armature 6 is equipped with a push rod 3 . The plug is connected to the power supply. When the power supply is energized, the current flows through the coil to generate a magnetic field, and the armature is magnetized to push the load forward; after the power is turned off, the electromagnetic force disappears, and the load pushes the armature back to zero. Within the effective stroke of the electromagnet, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com