A fully automatic cutting and trimming processing line for substrates used in photovoltaic power generation systems

A photovoltaic power generation system and trimming technology, applied in metal processing equipment, manufacturing tools, laser welding equipment, etc., can solve the problems of battery substrate defects, undetectable battery substrate cracks, etc., and achieve a close and tight automation process. effect of connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

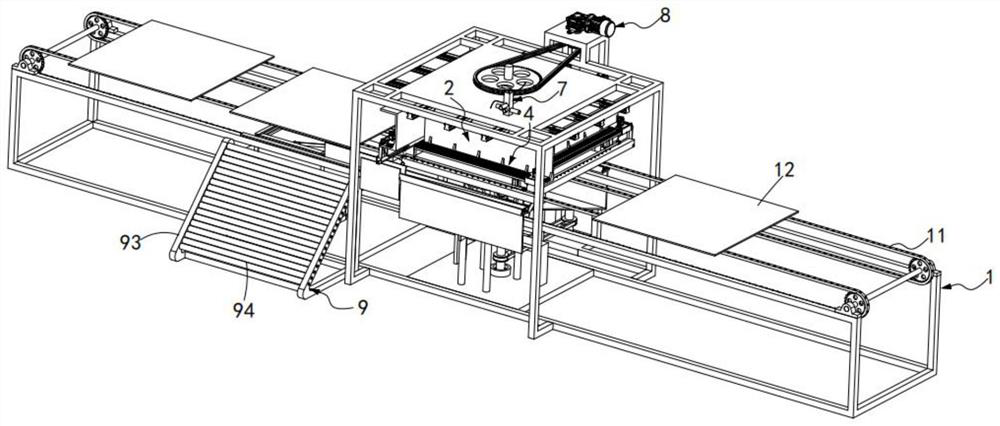

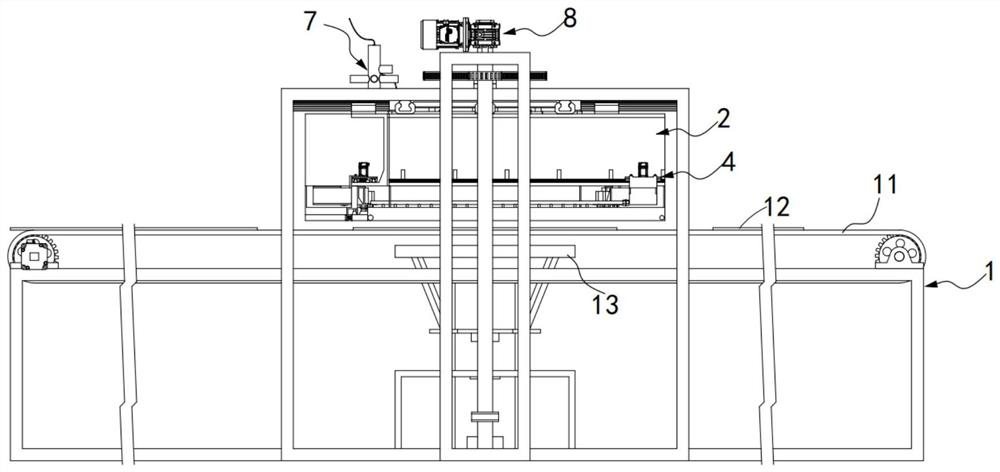

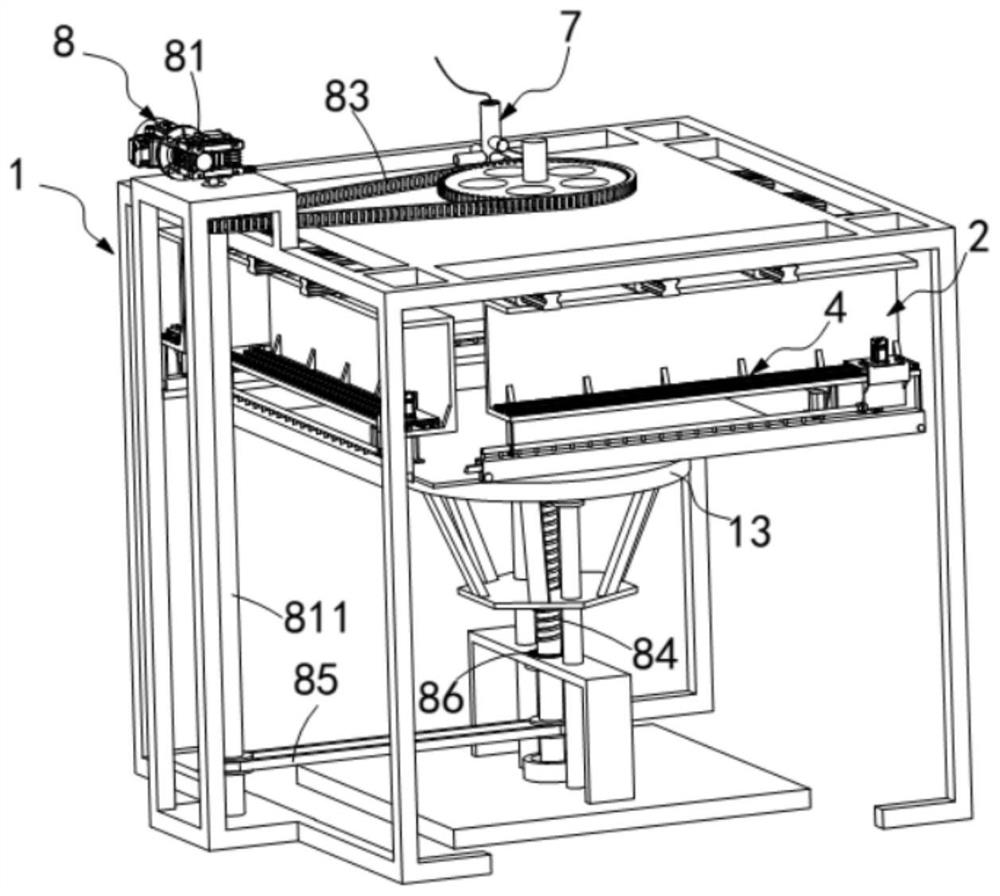

[0090] Such as Figure 1 to Figure 4 As shown, a substrate automatic cutting and trimming processing line for a photovoltaic power generation system includes a frame-shaped frame 1 and a conveying device 11 arranged on the frame 1 for horizontal transportation. The conveying device 11 conveys batteries equidistantly. The substrate 12, on the conveying path of the conveying device 11, is provided with a processing table 13 that moves up and down in the vertical direction, which pushes the battery substrate 12 conveyed by the conveying device 11 directly above it to be lifted up and conveyed, and also includes :

[0091] The mobile mounting plate 2 is slidably arranged on the frame 1 directly above the processing table 13 through a slide pair 21 composed of a slider and a guide rail, which is arranged around the processing table 13, and They are respectively arranged parallel to the sides facing the processing table 13, and the mobile mounting plates 2 are arranged to reciproca...

Embodiment approach

[0122] Such as Figure 10 to Figure 12 As shown, as a preferred embodiment, the control assembly 7 includes:

[0123] A control cylinder 71, the control cylinder 71 is vertically installed on the top of the frame 1;

[0124] An air inlet 72, the air inlet 72 is arranged on the control cylinder 71, communicates with an external air supply source through a pipeline, and is supplied by the external air supply source;

[0125] The first exhaust port 73, the first exhaust port 73 is symmetrically arranged on the control cylinder 71 along the axial direction of the control cylinder 71, which are respectively communicated with the corresponding detection assembly 3 through a pipeline, and supply air to the detection assembly 3;

[0126] Fixed lug 74, said fixed lug 74 is fixedly installed on the top of said control cylinder 71, and it is connected with moving motor 43 and laser cutting head 46 in said cutting assembly 4 by circuit;

[0127] Movable lug 75, the movable lug 75 is sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com