A fully automatic integrated processing line and processing method for lead-acid batteries

A lead-acid battery, integrated processing technology, applied in the direction of lead-acid battery, lead-acid battery construction, sustainable manufacturing/processing, etc., can solve the problems of low work efficiency, high labor cost, etc., to improve efficiency and quality, effectively and quickly take materials, to achieve the effect of automatic continuous nesting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

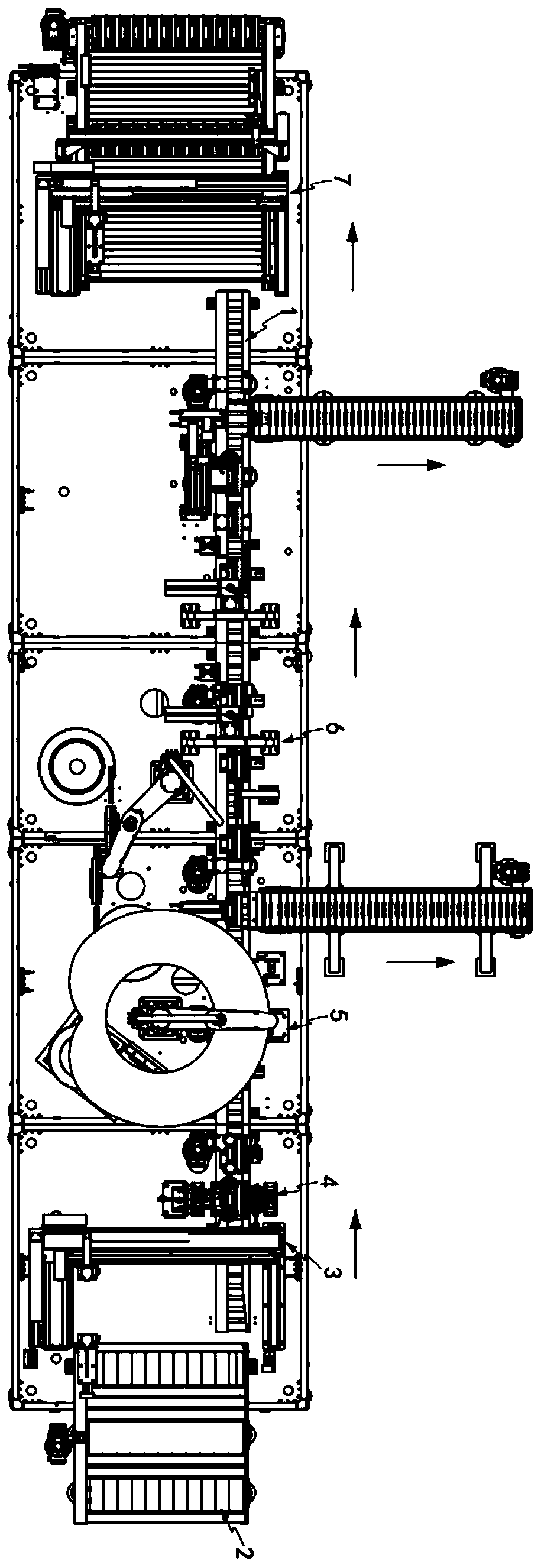

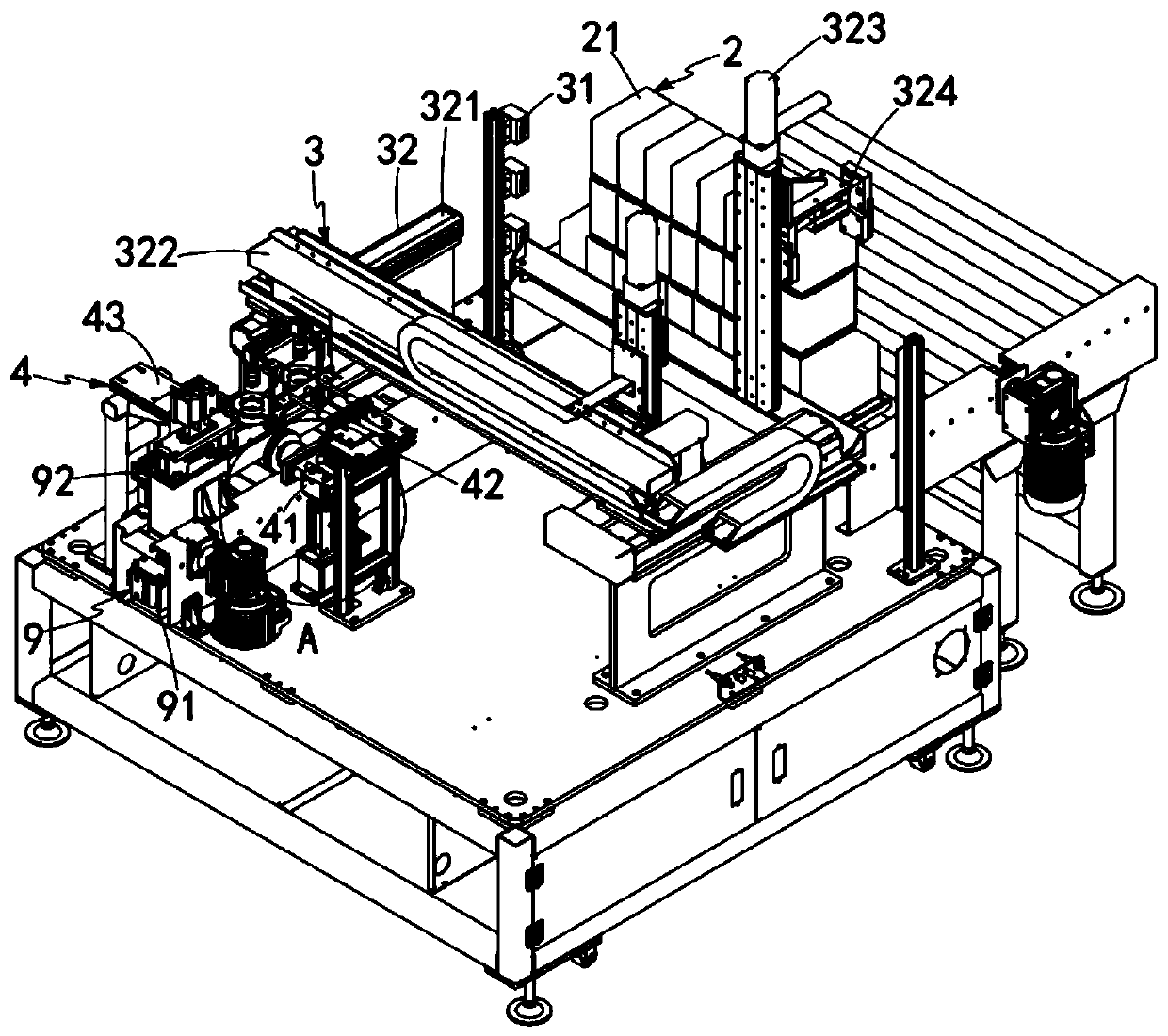

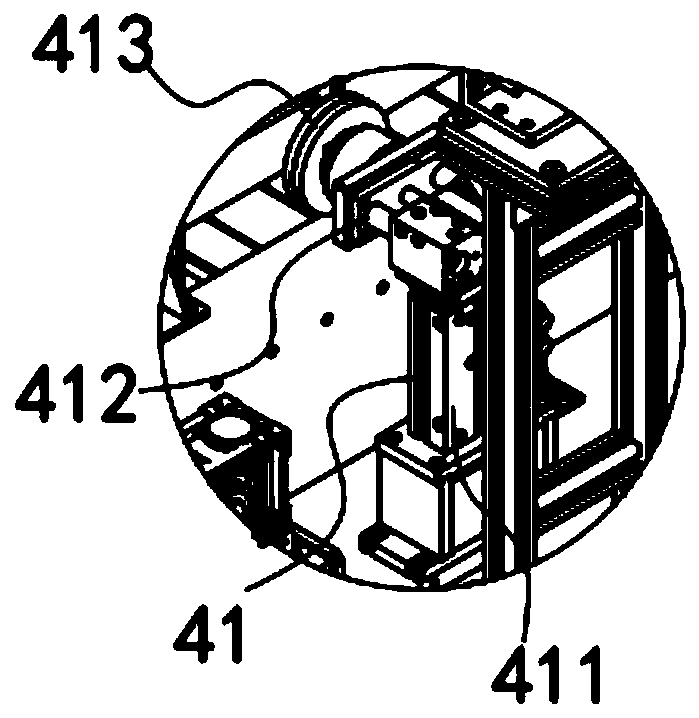

[0087] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 8 , Figure 11 and Figure 18 As shown, a fully automatic integrated processing line for lead-acid batteries after the lid is closed, including an automatic conveying line 1, along the conveying direction of the automatic conveying line 1, it also includes:

[0088] A battery stack 2, the battery stack 2 is arranged at the input end of the automatic conveying line 1, which includes a plurality of lead-acid batteries 21 stacked upside down;

[0089] The loading and clamping device 3, the loading and clamping device 3 is arranged at the rear end of the battery material pile 2, and it includes a positioning device fixed on one side of the automatic conveying line 1 for positioning the lead-acid battery 21 The mechanism 31 and the clamping mechanism 32 arranged above the automatic conveying line 1 can move and clamp the lead-acid battery 21;

[0090] An overturning detection device 4, the overturning detec...

Embodiment approach

[0136] Such as Figure 20 As shown, as a preferred implementation manner, the second detection mechanism 64 includes:

[0137] Mounting frame 641, the mounting frame 641 is a gantry structure, which is arranged on one side of the automatic conveying line 1;

[0138] A horizontal driving member 642, the horizontal driving member 642 is horizontally arranged on the top of the mounting frame 641, and its pushing direction is parallel to the conveying direction of the automatic conveying line 1;

[0139] A side pusher 643, the side pusher 643 is installed in the middle of the mounting frame 641, and its pushing direction is set horizontally and vertically to the conveying direction of the automatic conveying line 1;

[0140] A side pushing block 644, the side pushing block 644 is connected to the pushing end of the side pushing piece 643, and an arc-shaped bayonet 645 is provided at one end facing the automatic conveying line 1; and

[0141] A detection and determination unit 64...

Embodiment 2

[0146] Figure 8 and Figure 18 It is a structural schematic diagram of Embodiment 2 of the fully automatic integrated processing line after a lead-acid battery is closed; Figure 8 As shown, the parts that are the same as or corresponding to the first embodiment adopt the corresponding reference numerals of the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The second embodiment is similar to the first embodiment. figure 1 The difference of the shown embodiment one is:

[0147] Such as Figure 8 and Figure 18 As shown, a fully automatic integrated processing line after the lead-acid battery is closed, also includes a push-out device 8 arranged on the rear side of the air-tight detection mechanism 54 and the second detection mechanism 64, and the push-out device 8 includes:

[0148] Push out the cylinder 81, the said push-out cylinder 81 is horizontally arranged on one side of the automatic conveying l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com