A kind of preparation method of highly oriented graphene reinforced bismuth resin matrix composite material

A technology for strengthening resin-based and composite materials, applied in the field of materials science, can solve the problem of inability to highly orient graphene, and achieve the effect of improving mechanical properties, expanding the scope of application, and strengthening competition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

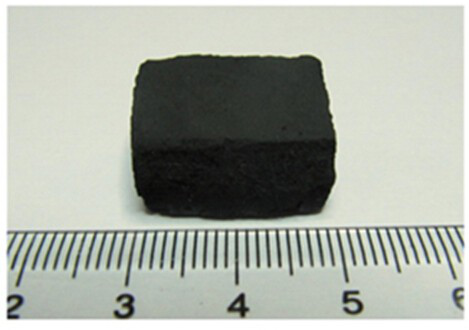

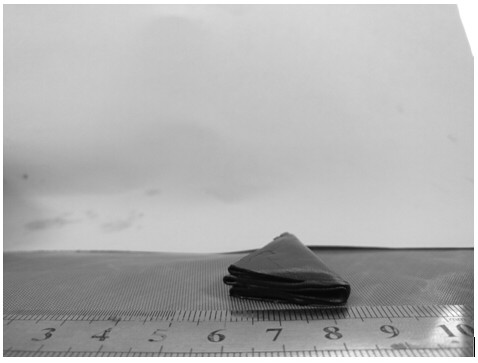

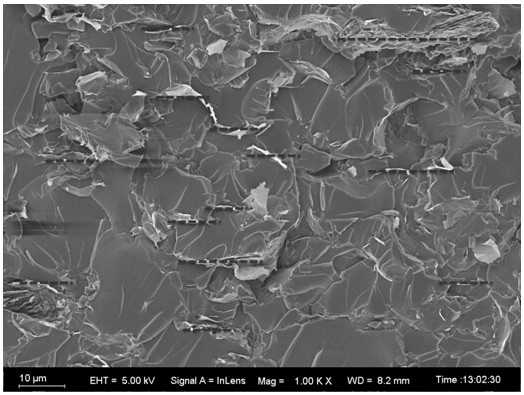

Image

Examples

specific Embodiment approach 1

[0026] Specific Embodiment 1: This embodiment provides a preparation method that can be used to prepare highly oriented graphene-reinforced double-horse resin-based composite materials. In the method, the three-dimensional graphene skeleton is prepared by vacuum infusion. The precursor of the composite material slurry , and then use high-speed stirring and ultrasonic-assisted method to prepare graphene resin-based composite material slurry, prepare oriented graphene-reinforced resin-based composite material precursor by controlling temperature field and force field, and finally prepare high-dispersion resin-based composite material by pressure gradient curing method Graphene-reinforced resin-based composites. Specifically include the following steps:

[0027] Step 1, the preparation of graphene sponge:

[0028] Method 1. Use the improved freeze-drying method to prepare graphene sponge. The specific steps are as follows: freeze the dispersed graphene aqueous solution with a co...

specific Embodiment approach 2

[0037] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, the concentration of the graphene aqueous solution is 5-10 mg / ml; the concentration of the graphene oxide aqueous solution is 5-20 mg / ml.

specific Embodiment approach 3

[0038] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: in step 1, the temperature used for the chemical reduction of hydrazine hydrate is 90°C, and the use time is 24 hours; the thermal reduction temperature is 600-800°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com