A mos-based 2 Method for preparing fracturing fluid from nanosheets

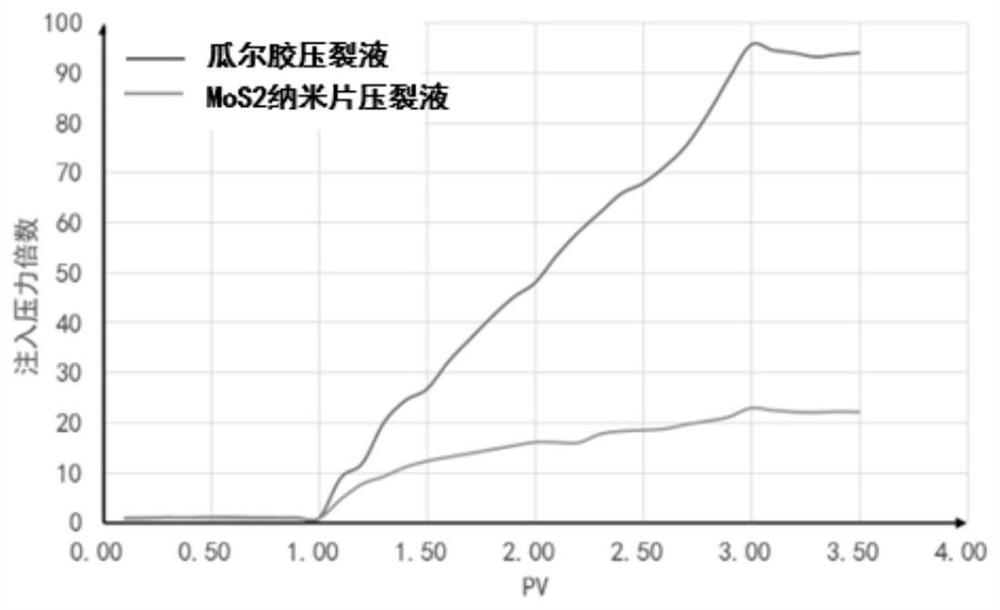

A nanosheet and fracturing fluid technology, applied in the field of fracturing fluid, can solve the problems of alkali-sensitive reservoir secondary damage, limitations, and imperfect acidic fracturing fluid technology, and achieve obvious speed-up and efficiency-enhancing effects and reduce requirements , Improve the effect of sand carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Preparation of modified guar powder:

[0029] Weigh 10g of guar powder, add it into a 100mL three-necked flask equipped with a stirring paddle, a thermometer and a reflux condenser; add 50mL of 95% ethanol for dispersion, then add 0.05g of catalyst NaOH, and stir for 0.5h under a constant temperature water bath at 45°C ; Add a certain amount of modifier octadecyl glycidyl ether to the solution, raise the temperature to 55°C, and stir for 4.5h. Cool after the reaction, filter with suction, and dry at low temperature (60°C) to obtain modified guar powder;

[0030] (2) Preparation of base liquid:

[0031] Pour 1000mL tap water into the mixer, turn on the mixer (800r / min), slowly add a certain amount of carboxymethyl hydroxypropyl guar gum into the mixer, after the liquid becomes viscous, use a pipette Pipette a certain amount of high-efficiency synergist G-ZP and clay stabilizer NW-1 into the mixer, adjust the speed of the mixer to 1000r / min and keep stirring for 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com