Tail gas waste heat recovery and turbine acceleration device

A technology of waste heat recovery and acceleration device, which is applied in the direction of exhaust device, muffler device, steam engine device, etc. It can solve the problems of limited net mechanical work, shortened engine life, increased impact force between piston and cylinder liner, etc., to increase available energy , reduce the average back pressure, improve the effect of acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

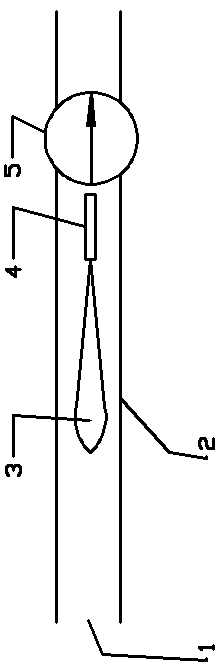

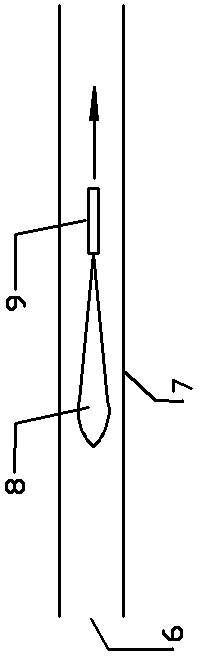

[0027] Such as figure 1 As shown, 1 is the turbine outlet, 2 is the tailpipe, 3 is the sprayed water mist, 4 is the water mist nozzle, and 5 is the end valve.

[0028] The present invention has two working modes:

[0029] 1. The water mist nozzle always works with the engine body and consumes a lot of water. When the high-temperature exhaust gas fills the entire tailpipe, the end valve is closed, water mist is sprayed, the pressure of the tailpipe drops significantly, the turbine accelerates, and the temperature of the exhaust gas flowing out of the turbine decreases relatively. When the gas in the tailpipe basically turns into low-temperature exhaust gas, the end valve opens, and the high-temperature exhaust gas squeezes out the low-temperature exhaust gas to start the next working cycle.

[0030] 2. The water mist nozzle only works when the turbine needs to be accelerated. When the turbine is running in a steady state, the sprayer does not work, saving water. Alternativel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com