Control rod guide clamp abrasion loss measurement method based on image recognition technology

A technology of technical measurement and image recognition, applied in the direction of measuring devices, character and pattern recognition, instruments, etc., can solve the problems of complex structure, detection equipment size, heavy weight, etc., to improve efficiency and reliability, facilitate follow-up management, details many effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

[0059] A method for measuring the amount of wear of a control rod guide card based on image recognition technology, comprising the following steps,

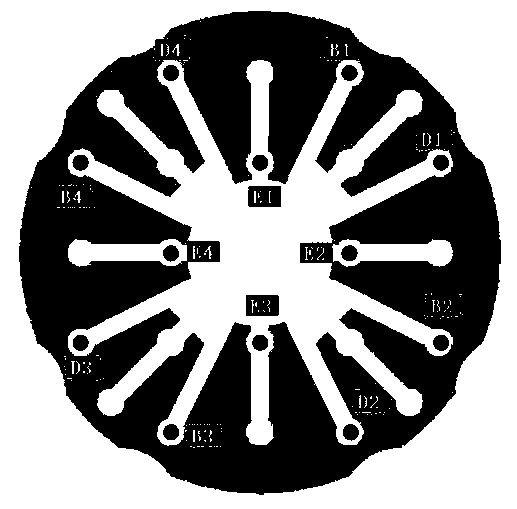

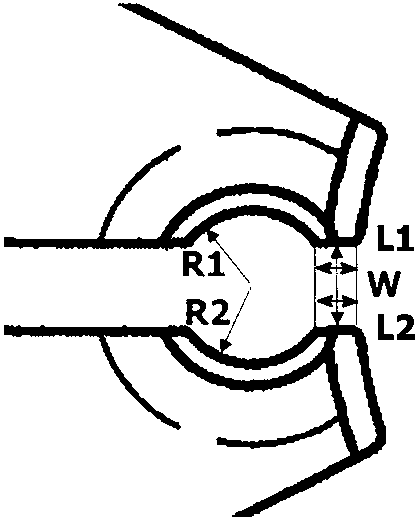

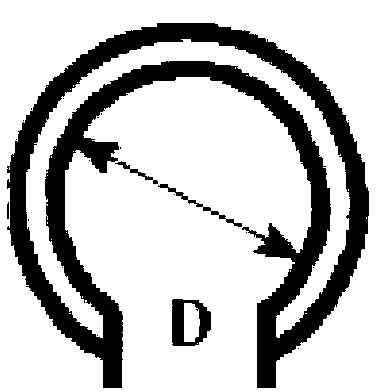

[0060] (1) Calibrate the detection range; Figure 1a , 1b , 1c, the calibration detection position: E1, E2, E3, E4, B1, B2, B3, B4, D1, D2, D3, D4 hole positions, measuring dimensions R1, R2, L1, L2, W, D.

[0061] (2) Image acquisition; 1. Camera, the camera needs to choose an industrial camera with stable and reliable performance, and the resolution is required to reach 5 million pixels. The actual detection environment is in the nuclear power plant pressure vessel pool with underwater radiation, and it is necessary to make waterproof and radiation-resistant Therefore, the size of the camera is required to be small (the maximum diameter of the detection hole is 61mm), and the focal leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com