Method for constructing surface shape mathematical model of circular tube type solar composite parabolic concentrator

A compound parabola and mathematical model technology, applied in solar thermal power generation, instruments, electrical digital data processing, etc., can solve problems such as difficulty in establishing differential equation solving process, hindering work development, complexity, etc., and achieve a simple and intuitive construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

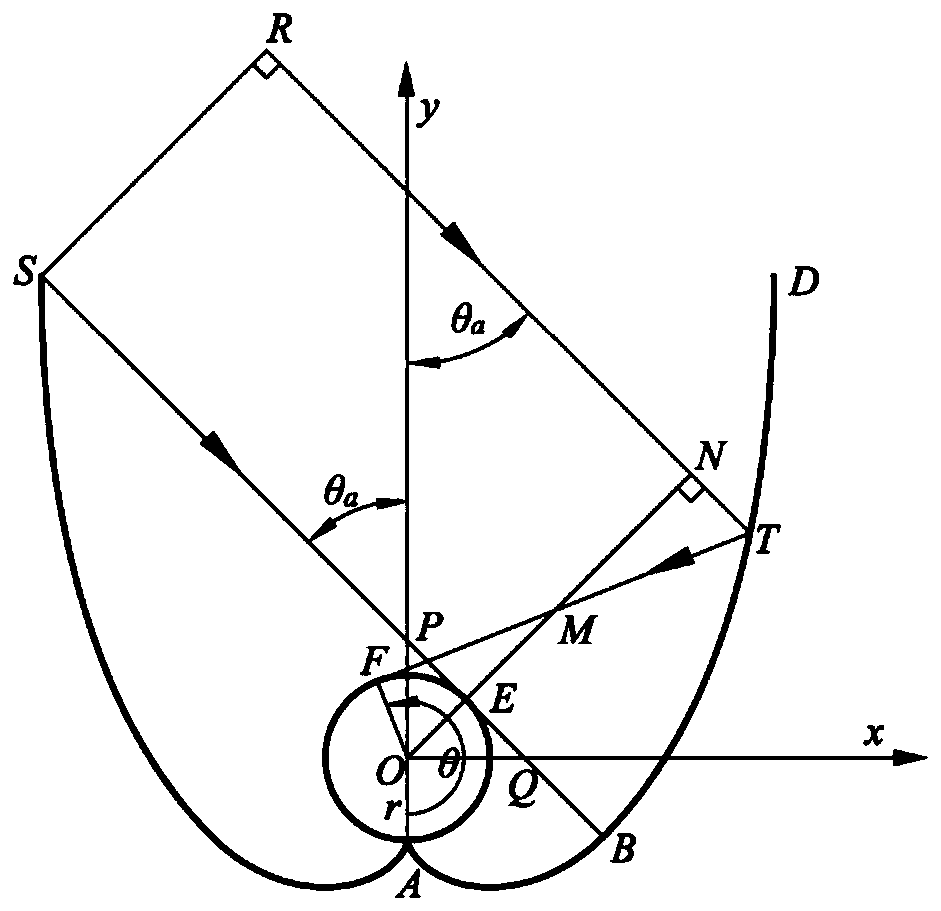

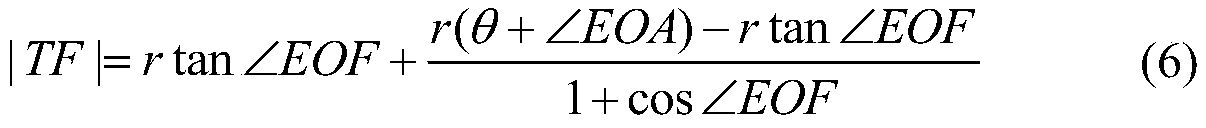

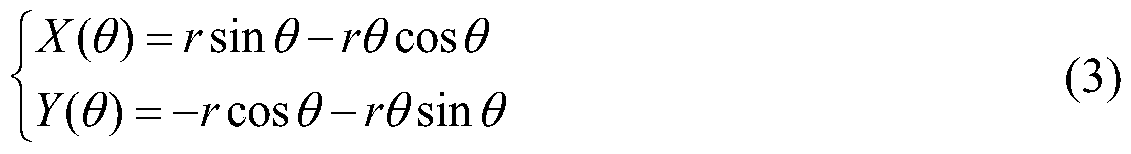

[0044] A method for constructing a mathematical model of a cylindrical solar compound parabolic concentrator, such as figure 1 As shown, on the cross-section of the circular tubular compound parabolic concentrator, the xoy coordinate system is established with the center O of the circular tube as the coordinate origin, and the CPC is composed of curves AD and AS symmetrical to the y-axis; among them, the right side of the CPC Half-branch curve AD is composed of involute AB and upper curve BD. The radius of the circular tube is r; the edge ray SB is tangent to the circular tube at point E, and the angle between the edge ray SB and the y-axis is called the receiving half angle θ a ; The angle between the radius corresponding to the reflected light tangent to the circular tube and the negative semi-axis of the y-axis is θ; the specific steps are as follows:

[0045] (1) Let any point on the involute AB be B(X,Y), then the abscissa X of point B is equal to the sum of the projected...

Embodiment 2

[0078] A method for constructing the mathematical model of the surface shape of a circular tubular solar compound parabolic concentrator, when the receiving half angle θ a =45°(0.25π), the mathematical model of the right half branch curve of CPC is:

[0079]

[0080]

[0081] The mathematical model of the left half of the CPC curve is:

[0082]

[0083] The U(θ) expression in Equation (16) is the same as Equation (15).

[0084] The mathematical model obtained by the method of the present invention is consistent with the result obtained by using the differential method in the literature "Research on Surface Model of Circular Absorber Composite Parabolic Concentrator and Simulation Verification".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com