Composite material battery box

A technology of composite materials and battery boxes, which is applied in the direction of battery boxes/coats, secondary batteries, battery covers/end covers, etc., can solve problems such as poor insulation performance, weak corrosion resistance, and a large number of molds, and achieve mileage deviation Controllable, excellent shock and noise reduction performance, and the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

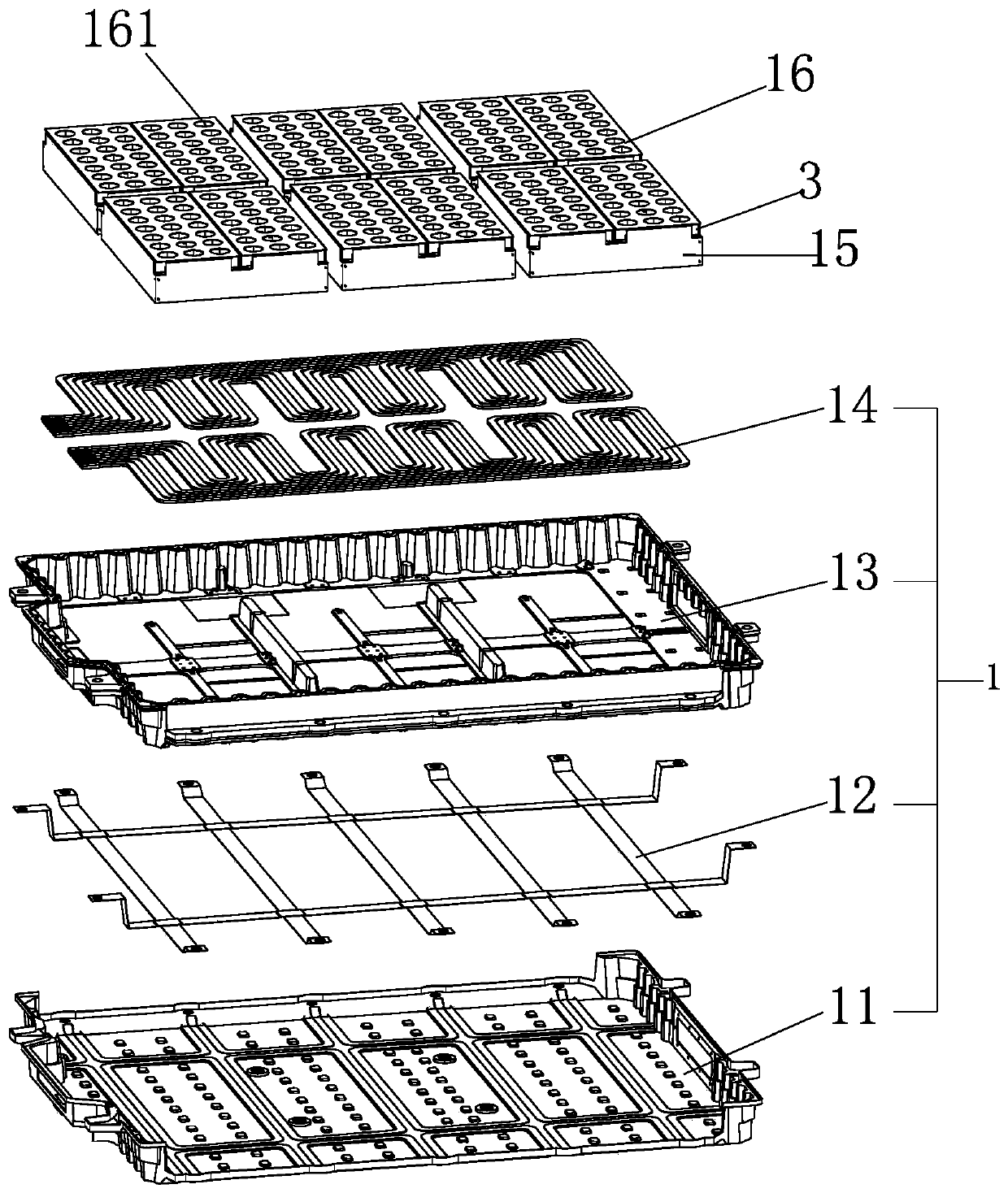

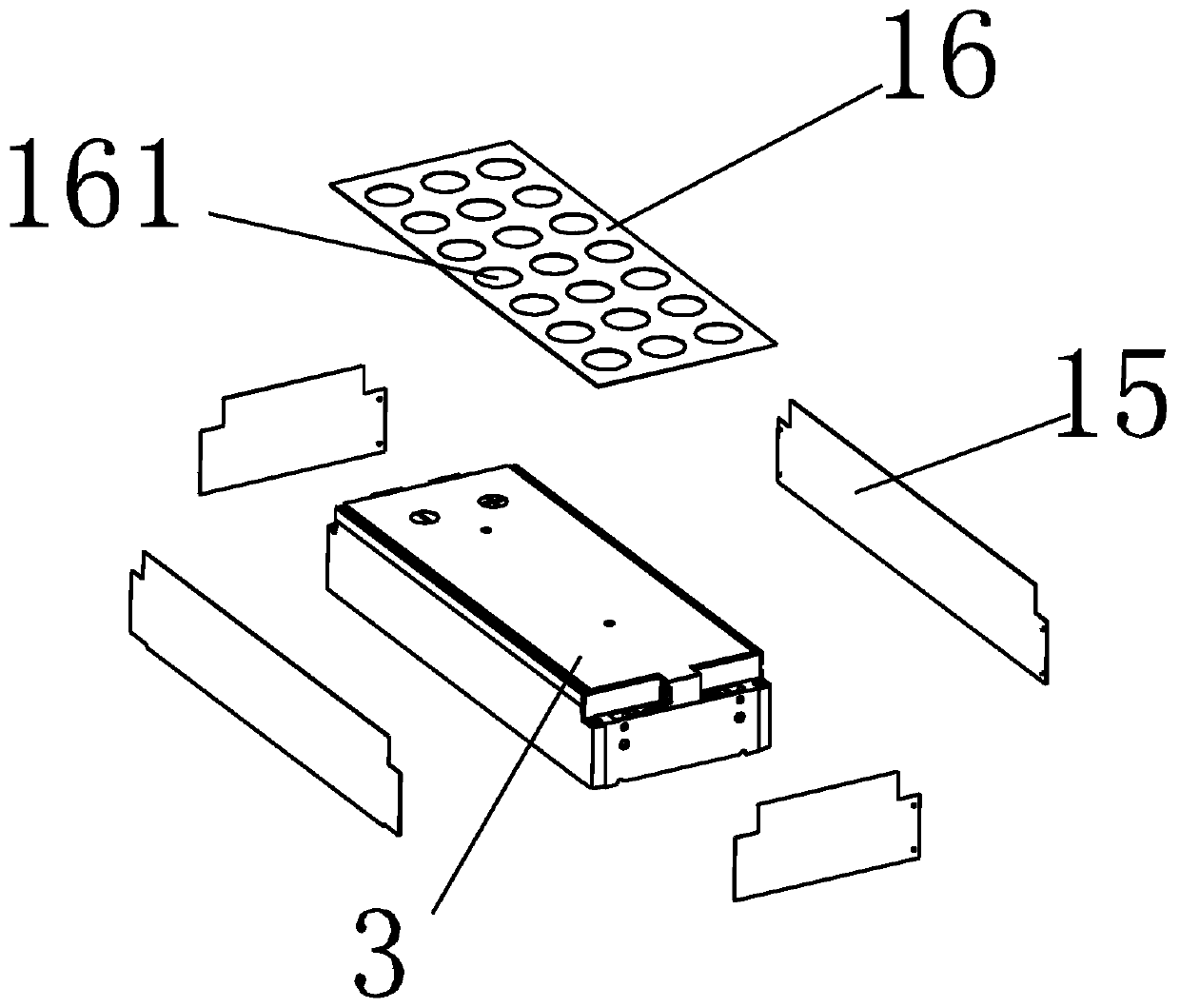

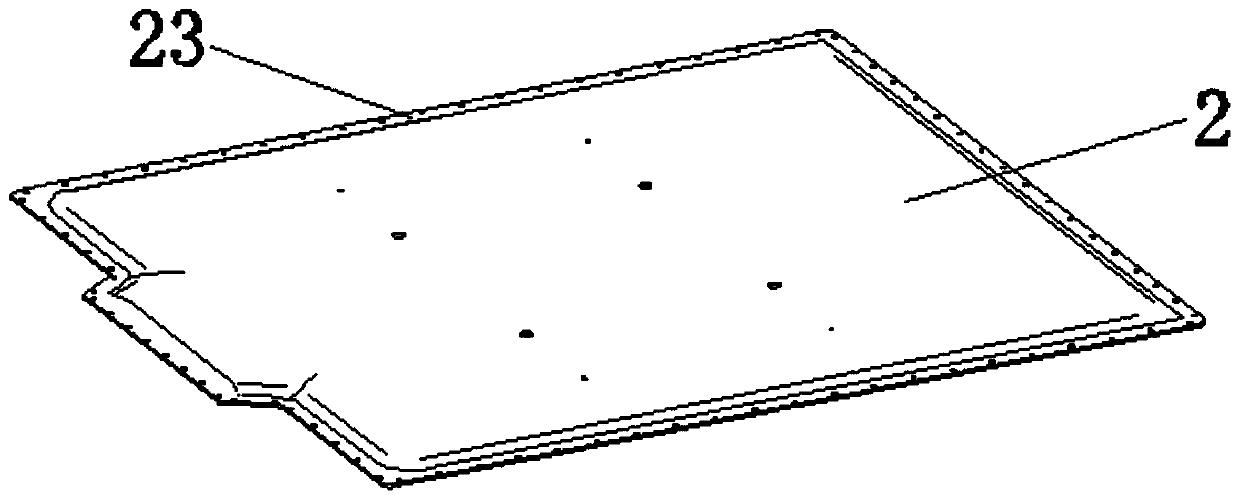

[0028] like figure 1 and figure 2 As shown, a composite material battery case of the present invention includes a lower case 1 and an upper cover 2, and the lower case 1 and the upper cover 2 are connected by bolts on the outer periphery. The lower casing 1 is a sandwich sandwich structure, including an outer casing 11 , a reinforcing bracket 12 and an inner casing 13 bonded together by structural adhesive. In one embodiment, the outer shell 11 is formed by compression molding of high-strength continuous long glass fiber prepreg; the reinforcing bracket 12 is made of metal material, such as aluminum alloy or No. 20 cold-rolled steel plate; the inner shell 13 is made of short glass fiber The SMC material is molded, and the middle of the inner shell 13 and the outer shell 11 is a reinforcing bracket 12, and the three are bonded with structura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com