Cooling system of self-baking electrode for brown corundum smelting in dump furnace

A self-baking electrode and cooling system technology, applied in electric heating devices, electrical components, heating by discharge, etc., can solve problems such as shortening the service life, and achieve the effect of improving the heat exchange effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

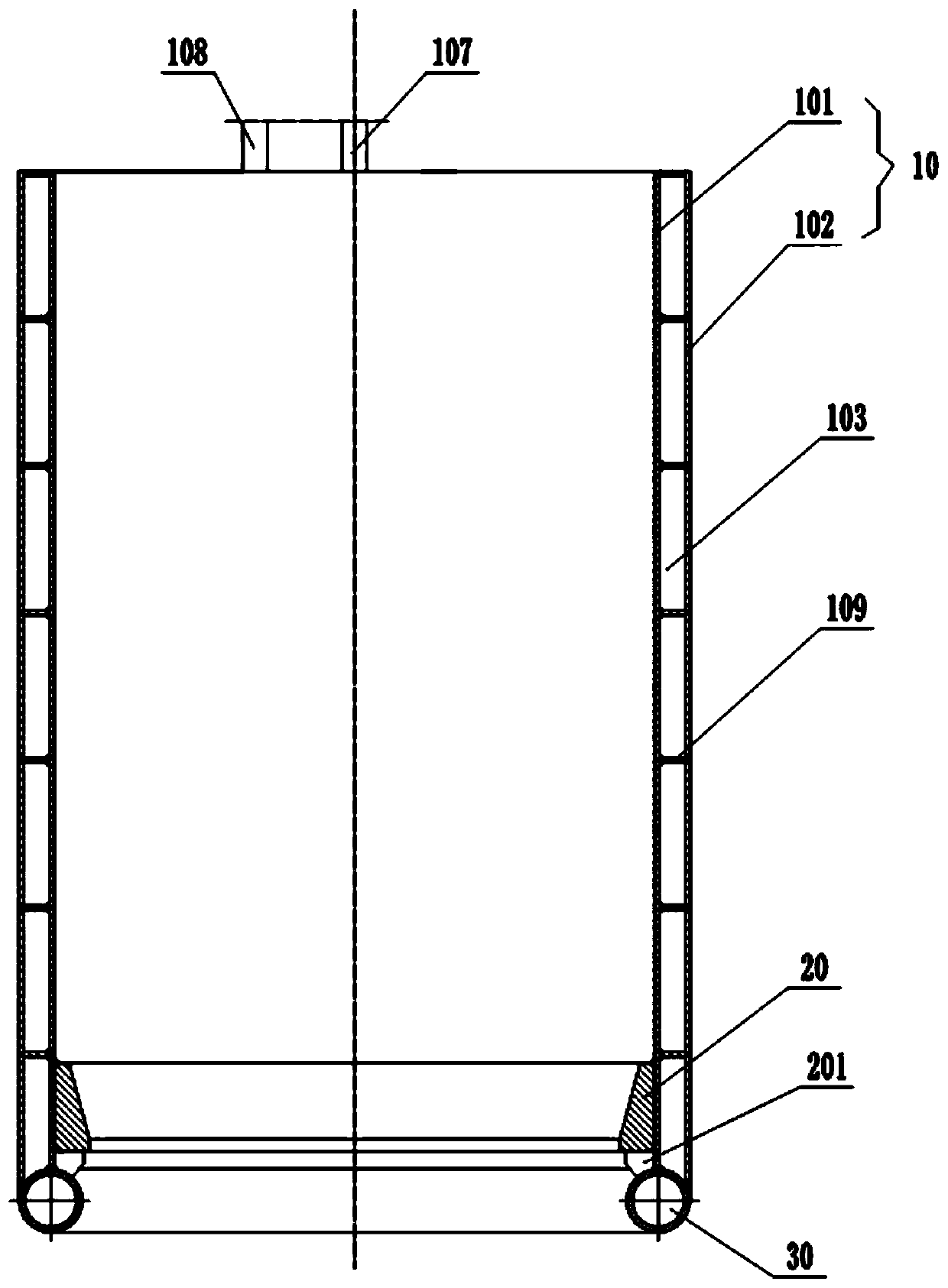

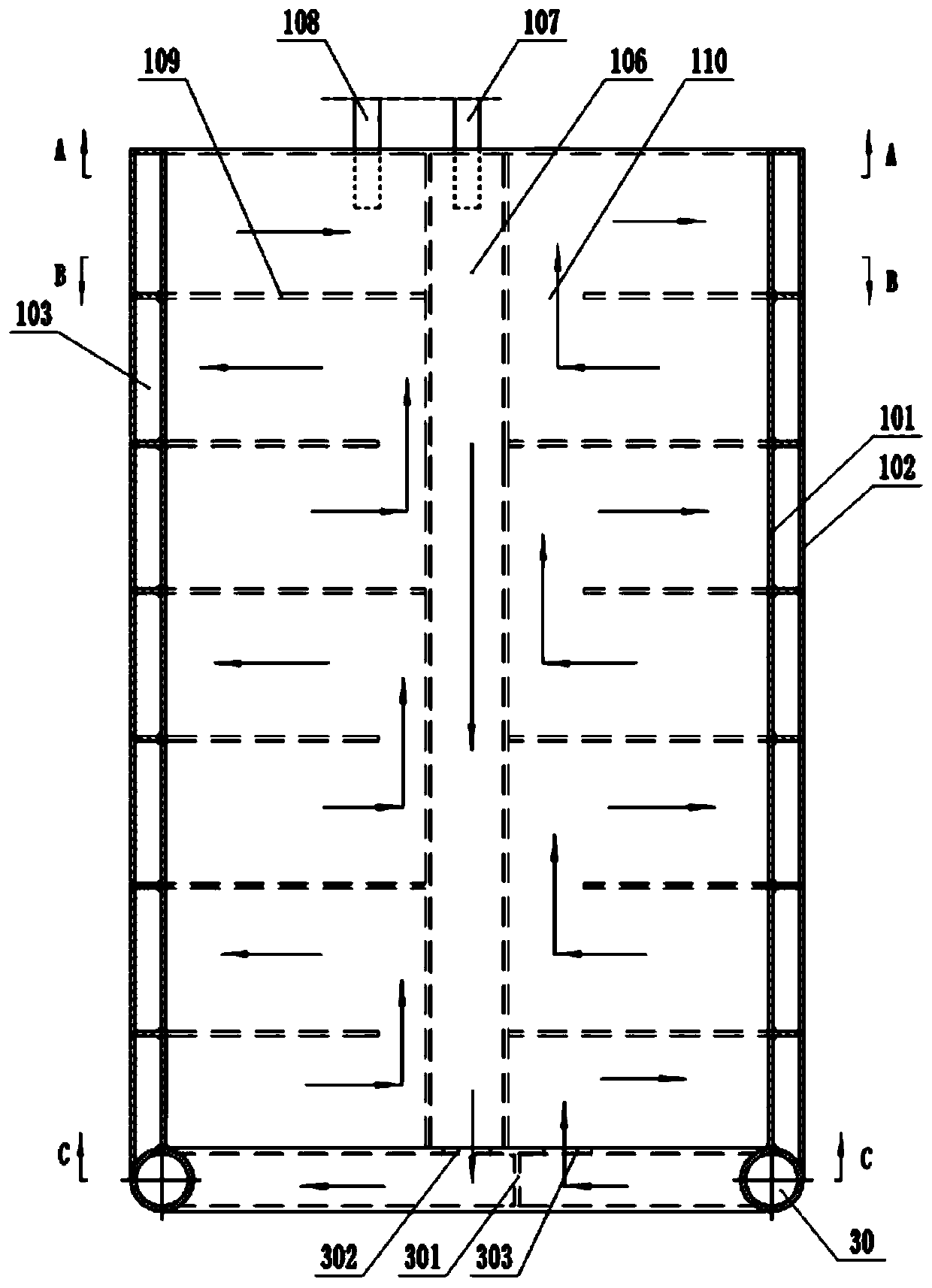

[0036] Embodiment 1 is basically as attached figure 1 and figure 2 Shown:

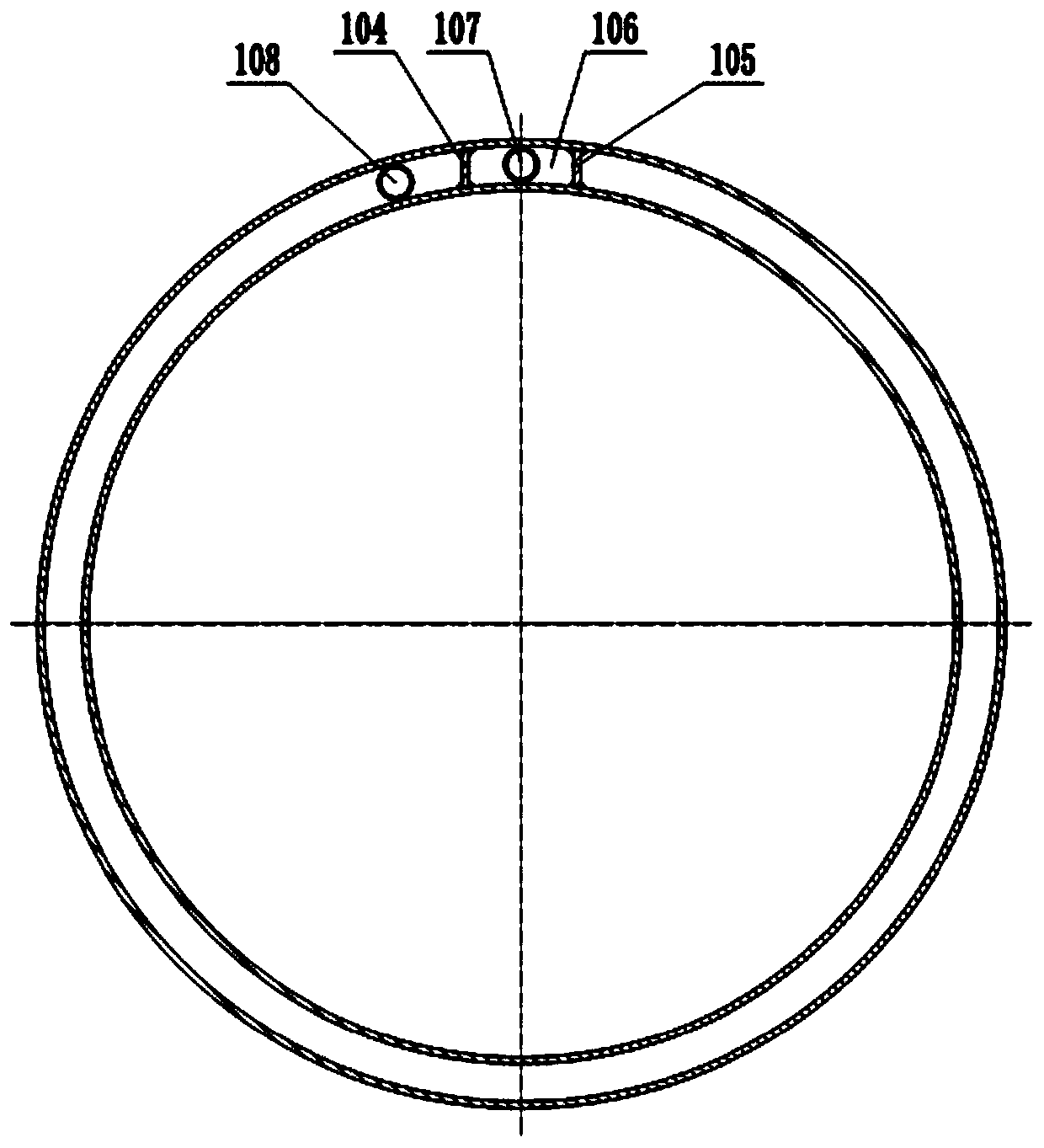

[0037] The self-baking electrode cooling system for smelting brown corundum in a dumping furnace includes a sheath 10, a tapered ring 20 and a hollow annular tube 30. The sheath 10 includes an inner layer 101 and an outer layer 102, and the annular tube 30 is welded to the inner layer At the bottom of the cover 101 and the outer cover 102, the tapered ring 20 is wide at the top and narrow at the bottom and is welded on the inner cover 101. Between the tapered ring 20 and the annular pipe 30, there is a connecting tapered ring 20, an annular The support plate 201 of the tube 30 and the inner layer cover 101, the inner layer cover 101, the outer layer cover 102 and the annular tube 30 form a closed cooling cavity 103, combined image 3 As shown, in the cooling cavity 103 along the axial direction of the sheath 10, a guard plate I 104 and a guard plate II 105 are welded, and a water inlet chamber 106 i...

Embodiment 2

[0043] Embodiment 2 is basically as Figure 6 Shown:

[0044] The difference from Embodiment 1 is that a deflector 40 is welded between both sides of the water deflector 301 and the inner wall of the annular pipe 30, and the upper surface of the deflector 40 on the right side of the water deflector 301 faces the water outlet 303, The upper surface of the deflector 40 on the left side of the water deflector 301 faces the water inlet 302, and the angle between the deflector 40 and the water deflector 301 is 20°-30°, and the included angle in this embodiment is 25° , in addition, the water inlet 302 and the water outlet 303 can all or partly be projected on the deflector 40 in the vertical direction.

[0045] Arranged like this, because when cooling water enters the annular pipe 30 through the water inlet 302, the water flow flowing to the water baffle 301 will form "retention" (that is, the flow velocity slows down), and the setting of the deflector 40 can allow the "delay" her...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com