Glass frit, glass frit production method, and aluminium paste

A manufacturing method and technology of glass frit, applied in the direction of quartz/glass/glass enamel, conductive materials dispersed in non-conductive inorganic materials, metal/alloy conductors, etc., can solve problems such as weak tensile strength and eliminate warping , Eliminate the effects of low life expectancy and easy vitrification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

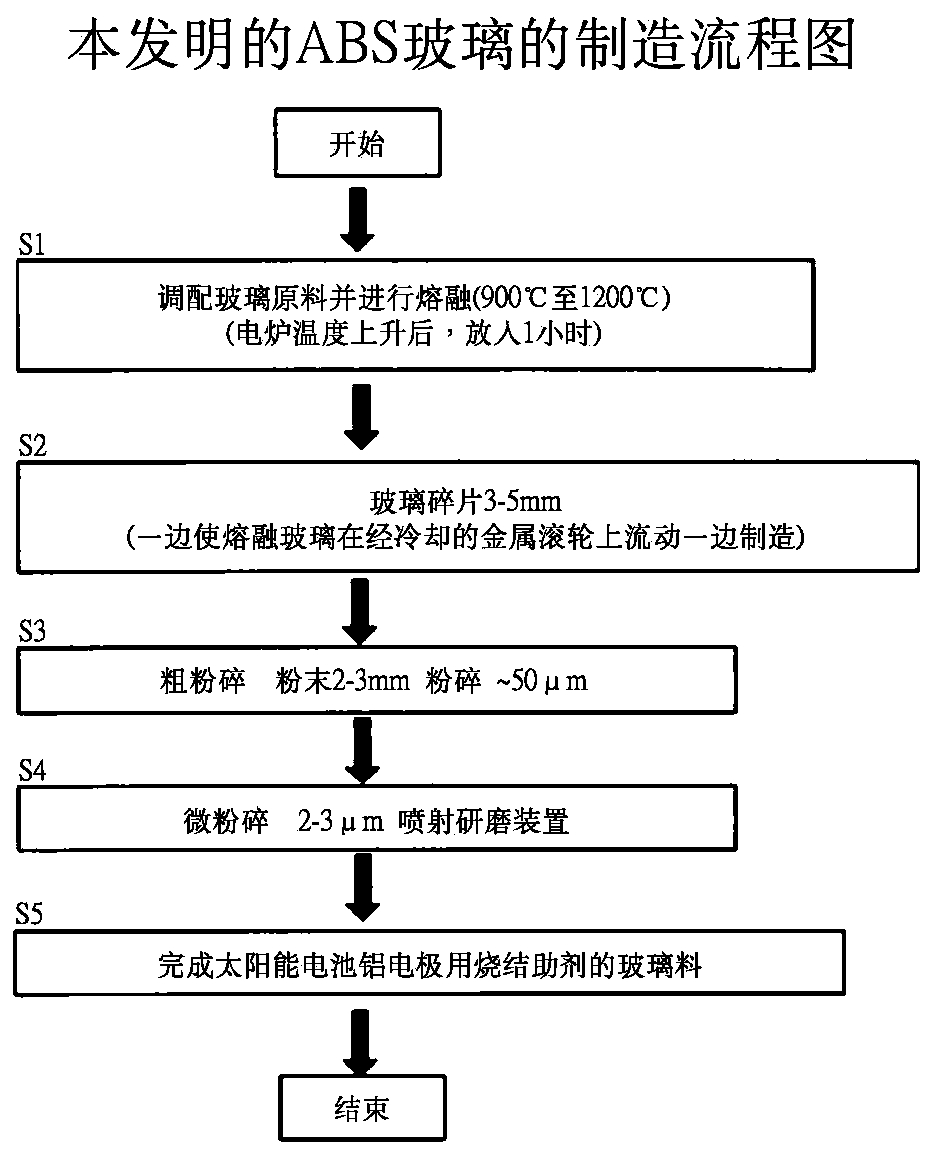

[0028] figure 1 The manufacturing flow chart of the ABS glass (Art Beam solar cell glass) of this invention is revealed.

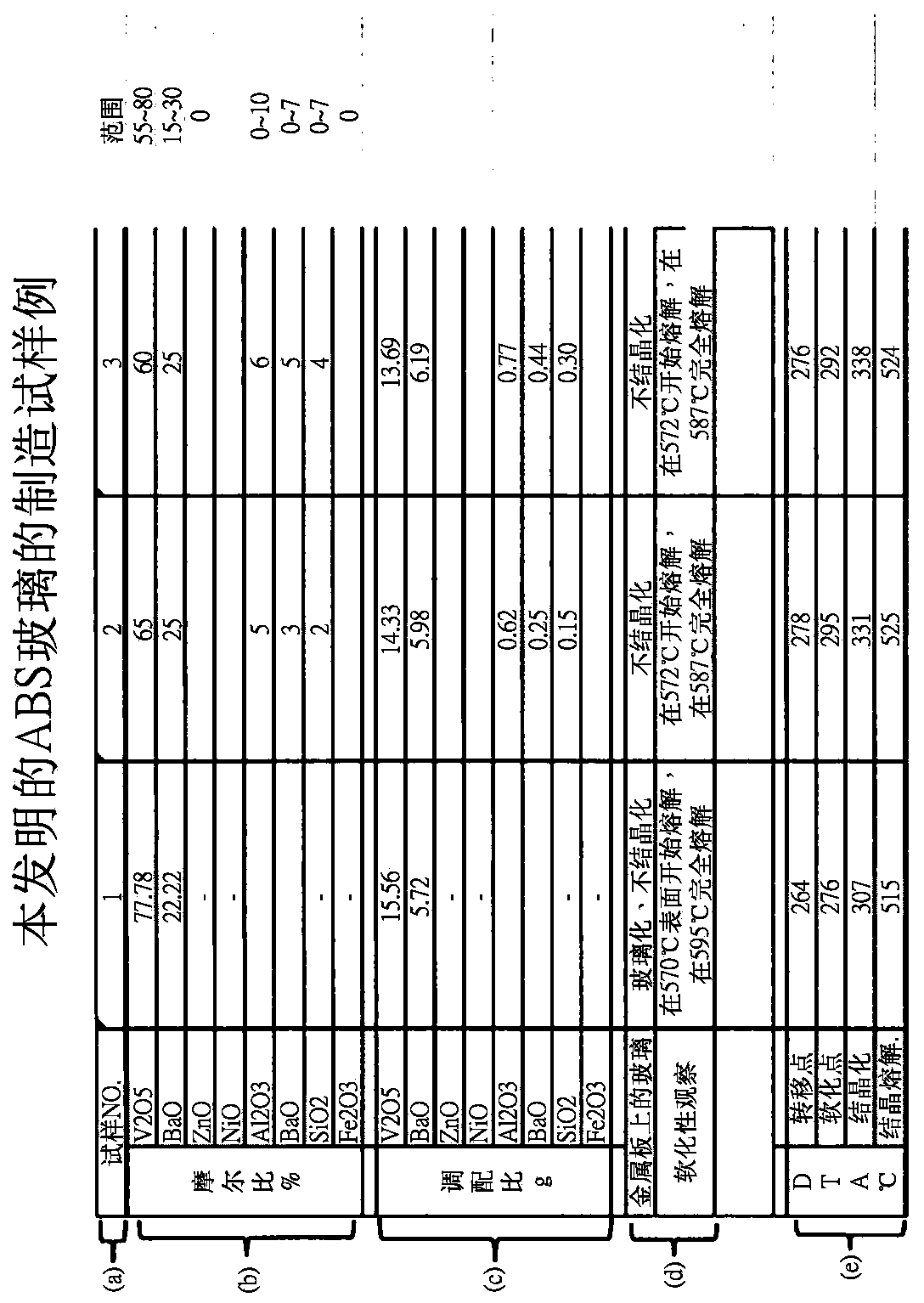

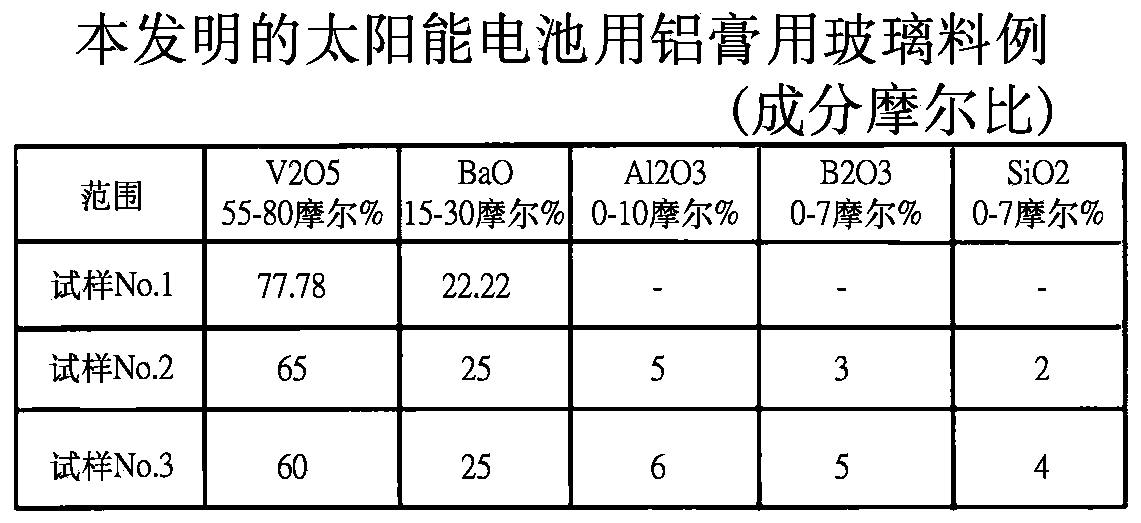

[0029] exist figure 1 , S1 Prepare and melt glass raw materials (900°C to 1200°C) (after the temperature of the electric furnace rises, add and leave for 1 hour). This is when the temperature of the electric furnace is raised to the optimum temperature determined by experiments in the range of 900°C to 1200°C, the prepared glass raw material is put into the crucible, inserted, dissolved and left for 1 hour. Alternatively, the raw material put in the crucible may be melted and left to stand for 1 hour by raising the temperature to a predetermined temperature in an electric furnace. In the experiment, the glass raw material is, for example, the following figure 2 Displayed below etc.

[0030]

[0031]

[0032] S2 produces glass shards (3 to 5mm). As described below, the molten glass produced in S1 was produced while flowing on the cooled metal ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com