Light stabilizer, preparation method and uses thereof

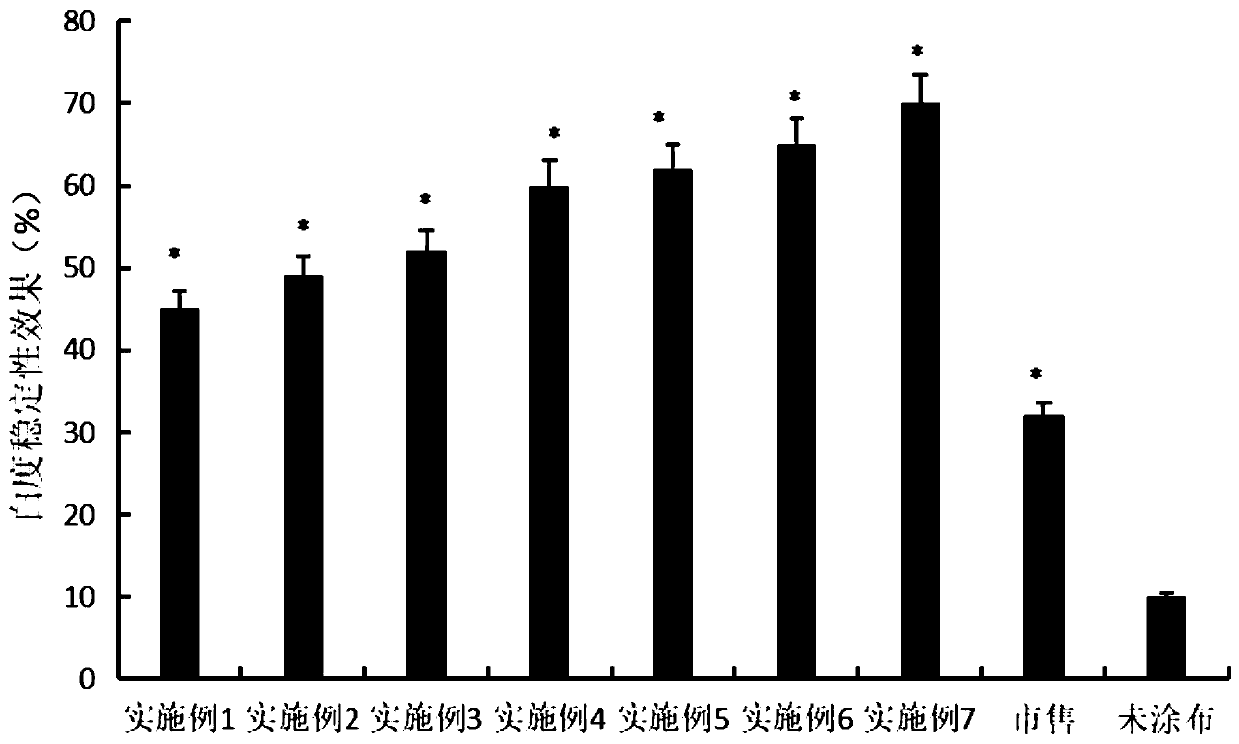

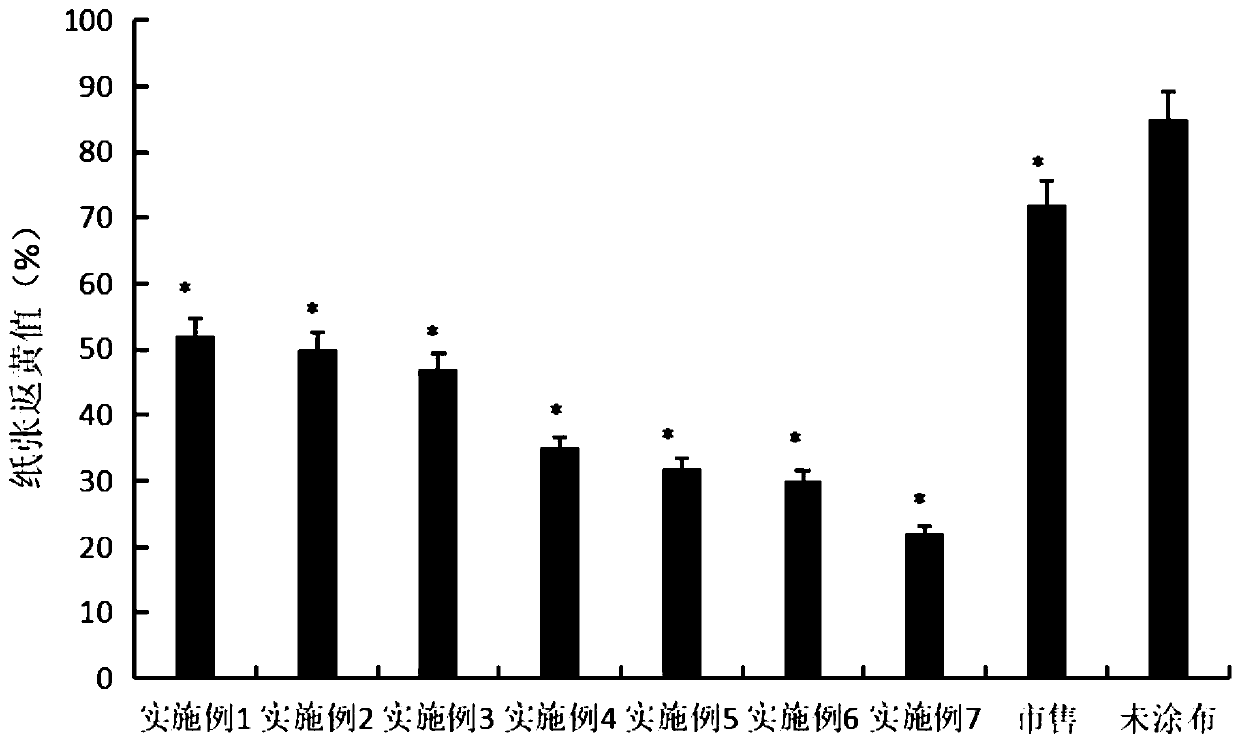

A technology of light stabilizer and active agent, applied in the field of light stabilizer and its preparation, can solve the problems of unstable whiteness of high-yield pulp, high input cost, limited scope of use, etc., and achieve the effect of good light stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

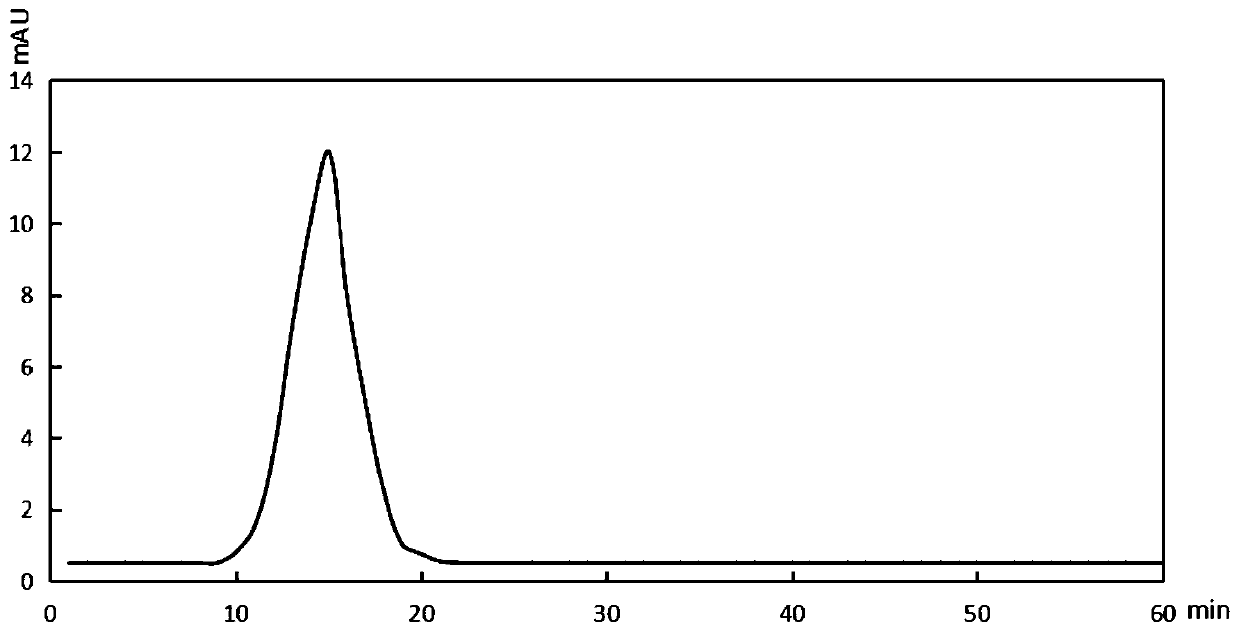

Image

Examples

Embodiment 1

[0026] A preparation method of light stabilizer, comprising the following steps:

[0027] S1. Dissolve 1 mol of methyl salicylate in dichloromethane, slowly add 1.2 mol of thionyl chloride dropwise under ice bath, stir while dropping, at a speed of 200r / min, continue to stir for 2 hours after the dropwise addition, and stop the reaction , the solvent was removed by rotary evaporation, washed with water, and suction filtered to obtain the intermediate;

[0028] S2. Add 1.2mol 2,2',6,6'-tetramethylpiperidinamine to the reaction kettle, adjust the pH value to 5 with 1mol / L hydrochloric acid solution, control the reaction temperature to 10°C, and add 1mol intermediate At the same time, the temperature is gradually raised to 50°C, and the reaction continues until the pH value does not change. Slowly raise the temperature to 85°C, react until the amino value disappears, cool to room temperature, distill under reduced pressure, wash repeatedly with acetone, and dry to obtain photosta...

Embodiment 2

[0030] A preparation method of light stabilizer, comprising the following steps:

[0031] S1. Dissolve 1 mol of methyl salicylate in dichloromethane, slowly add 1.5 mol of thionyl chloride dropwise under ice bath, stir while dropping, at a speed of 500r / min, continue to stir for 3 hours after the dropwise addition, and stop the reaction , the solvent was removed by rotary evaporation, washed with water, and suction filtered to obtain the intermediate;

[0032] S2. Add 1.5mol 2,2',6,6'-tetramethylpiperidinamine to the reaction kettle, adjust the pH value to 6 with 2mol / L hydrochloric acid solution, control the reaction temperature to 15°C, and add 1mol intermediate At the same time, the temperature is gradually raised to 60°C, and the reaction continues until the pH value does not change. Slowly raise the temperature to 90°C, react until the amino value disappears, cool to room temperature, distill under reduced pressure, wash repeatedly with acetone, and dry to obtain photosta...

Embodiment 3

[0034] A preparation method of light stabilizer, comprising the following steps:

[0035] S1. Dissolve 1 mol of methyl salicylate in dichloromethane, slowly add 1.35 mol of thionyl chloride dropwise under ice bath, stir while dropping, at a speed of 350r / min, continue to stir for 2 hours after the dropwise addition, and stop the reaction , the solvent was removed by rotary evaporation, washed with water, and suction filtered to obtain the intermediate;

[0036] S2. Add 1.3mol 2,2',6,6'-tetramethylpiperidinamine to the reaction kettle, adjust the pH value to 5.5 with 1.5mol / L hydrochloric acid solution, control the reaction temperature to 12°C, and drop 1mol intermediate At the same time, the temperature is gradually raised to 55°C, and the reaction continues until the pH value does not change. Slowly raise the temperature to 87°C, react until the amino group value disappears, cool to room temperature, distill under reduced pressure, wash repeatedly with acetone, and dry to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com