Steel for steel structure bolts

A technology for steel structures and bolts, applied in the field of fastener materials, to achieve high-strength performance grades, uniform precipitation, and prevention of grain boundary cracking.

Active Publication Date: 2021-03-23

LUOYANG SUNRUI SPECIAL EQUIP

View PDF17 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

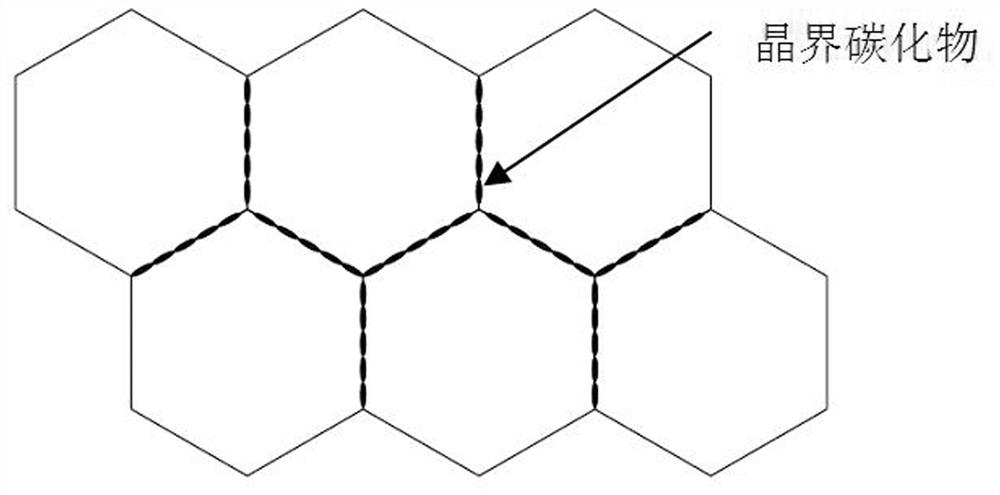

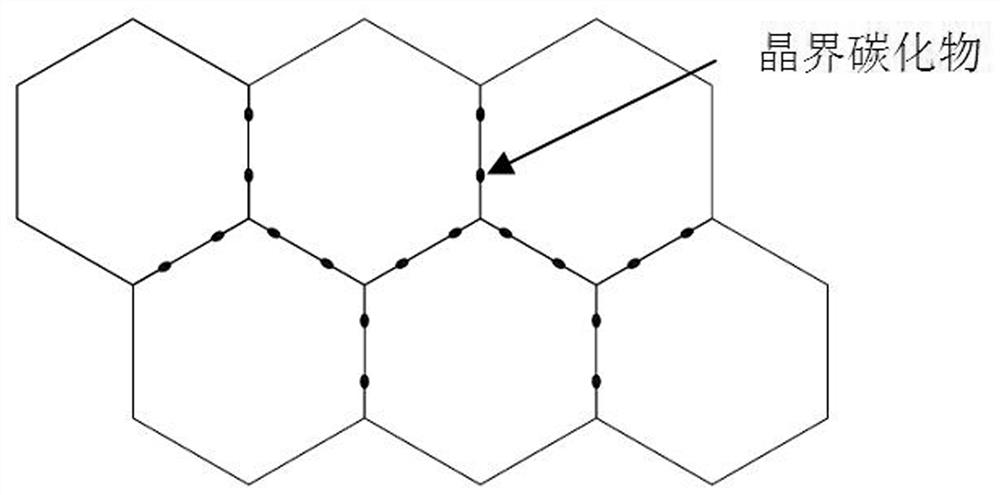

[0008] In improving the delayed fracture resistance of the material matrix, the crack source area of the delayed fracture bolts in practical applications shows intergranular fracture morphology, and the existing patents rarely have targeted solutions.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

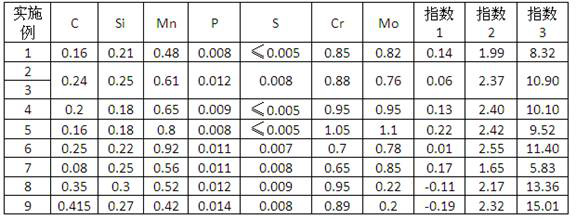

[0044] A 50Kg steel ingot was smelted in a vacuum furnace. The chemical analysis composition of the smelted material is shown in Table 1: billet forging to a φ38mm round bar, sawing and turning to a φ33*200mm smooth bar.

[0045] Table 1, embodiment chemical composition and performance index

[0046]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

A kind of steel for steel structure bolts, the steel material contains C: 0.1~0.3, Si: 0.10~0.35, Mn: ≤1.5, S≤0.01, P≤0.015, Cr: 0.5~1.4, Mo: 0.6~1.2 in mass percentage , the rest is Fe, unavoidable impurities, and the tempering temperature of the steel material is ≥600°C during the final heat treatment. The present invention is based on the actual steel structure application environment and the fracture morphology of the existing delayed fracture fracture analysis, and optimizes the alloy composition to improve the precipitation quantity and precipitation form of grain boundary carbides and improve the delayed fracture resistance of the material. The tensile strength of the invented steel for steel structure bolts can reach more than 1040MPa after heat treatment, and the upper limit can reach 1240MPa. The performance grade of the fastener meets GB / T1231-2006 standard 10.9S grade, and has excellent resistance to delayed fracture.

Description

technical field [0001] The invention belongs to the field of fastener materials, and specifically relates to a high-strength steel structure bolt steel with good delayed fracture resistance and formability, which is suitable for the manufacture and production of large hexagon head bolts and flange surface bolts for steel structures. application. Background technique [0002] Steel structure large hexagonal head bolts have large size and specifications, large hexagonal opposite sides, large deformation of the head for upsetting and forging, and high requirements on the plasticity of the bolt material. For example, the common size of large hexagonal head bolts for railway steel structure bridges is M22 ~ M30. For example, in the GB / T1231-2006 standard, the 10.9S grade bolt materials are: 20MnTiB, ML20MnTiB, 35VB, etc. Medium and low carbon B steel has been widely used in the field of fasteners due to its low content of alloy elements, good plastic formability, and low cost. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C38/02C22C38/04C22C38/22C21D1/18

CPCC21D1/18C22C38/02C22C38/04C22C38/22

Inventor 范芳雄陈继志杨俊峰孙永伟

Owner LUOYANG SUNRUI SPECIAL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com