Multifunctional rock-soil test model box

A test model, multi-functional technology, applied in the direction of soil material testing, material inspection products, using stable tension/pressure testing material strength, etc., can solve the problem of loading equipment positioning, cumbersome fixing, inability to guarantee test accuracy, and model box functions Single and other problems, to achieve the effect of saving manpower and material resources, wide applicability, and complete functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

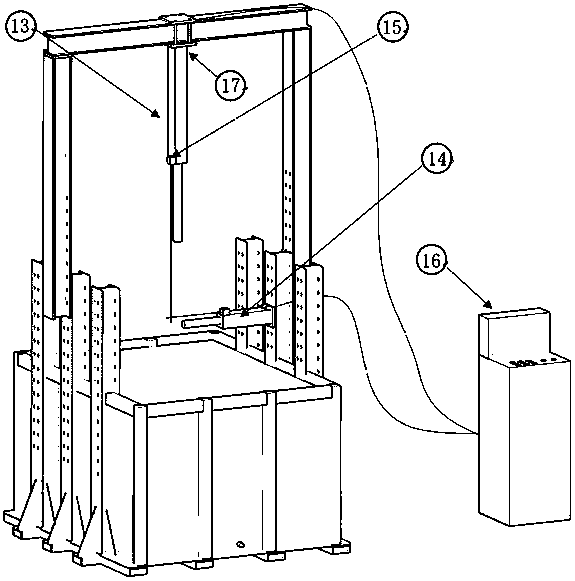

[0040] Application of loading and collecting devices. like image 3 As shown, reference numerals: 13, vertical loading actuator, 14, horizontal loading actuator, 15, laser displacement sensor, 16, control and acquisition system, 17, movable support.

[0041] The beam 9 is equipped with a vertical loading actuator 13 (which may be a servo oil cylinder or a servo electric cylinder). The connection method of the upper part of the actuator can ensure that the actuator can move freely along the length direction of the beam, and realize the vertical force or displacement loading on the structure.

[0042] There are several rows of bolt holes on the inner side of the anti-column 1, and there is a horizontal loading actuator 14, which can be fixed to the anti-column by bolts to realize horizontal force or displacement loading on the structure, and the position can be changed up and down.

[0043] The loading actuators are all equipped with force sensors. Through the vertical and hor...

Embodiment 2

[0048] Application of vacuum consolidation system. like Figure 4 As shown, reference signs: 18, reverse filter layer, 19, geotextile, 20, water storage tank, 21, negative pressure pump.

[0049] Vacuum consolidation systems include:

[0050] Reverse filter layer 18: composed of stones or sand, filled into the bottom of the model box, the height is higher than the height of the drain valve;

[0051] Geotextile 19: covered on the reverse filter layer to prevent flowing soil;

[0052] Water storage tank 20: connected to the drain valve 8 through a water pipe, fully sealed, used to store the extracted water;

[0053] Negative pressure pump 21: connected to the water storage tank, and applying negative pressure to the model box through the water outlet pipe.

[0054] During vacuum consolidation, a layer of plastic film is covered on the upper part of the model box, and the negative pressure pump, water storage tank and model box are connected. Turn on the negative pressure pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com