Current detector based on metal-dielectric-metal waveguide

A detector and metal technology, applied in the field of current detection, can solve problems such as reducing the detection performance of the detector, and achieve the effects of small structure size, wide amplitude and high detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

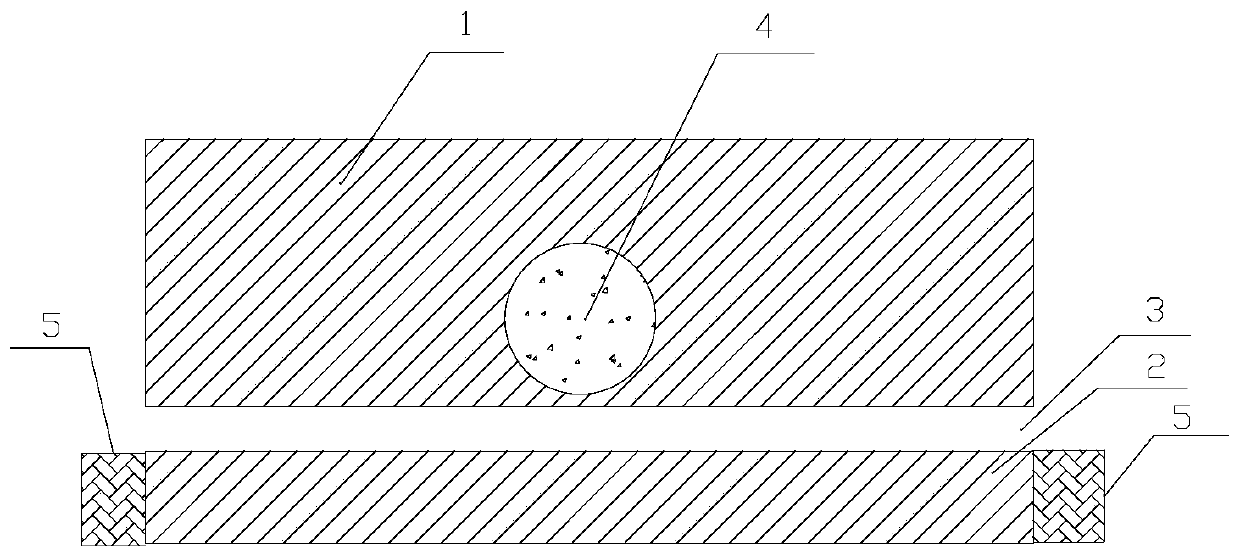

[0020] The present invention provides a figure 1 The current detector based on the metal-dielectric-metal waveguide shown includes a substrate and a first metal plate 1 placed on the substrate, a second metal plate 2, an electrode 5, the first metal plate 1 and The second metal plate 2 is arranged in parallel, and a gap 3 is formed between the first metal plate 1 and the second metal plate to form a metal-dielectric-metal waveguide. The width of the slit 3 is less than 60 nanometers to support only basement membrane transport. Electrodes 5 are connected to both ends of the second metal plate 2 . A cavity 4 is provided on the first metal plate 1 , and a magnetic fluid is provided in the cavity 4 . The substrate is magnesium fluoride crystal. The magnetic fluid is water-based ferroferrofluid. The material of the first metal plate 1 and the second metal plate 2 is gold. In application, the optical fiber is used to couple light into the slot 3 of the metal-dielectric-metal wa...

Embodiment 2

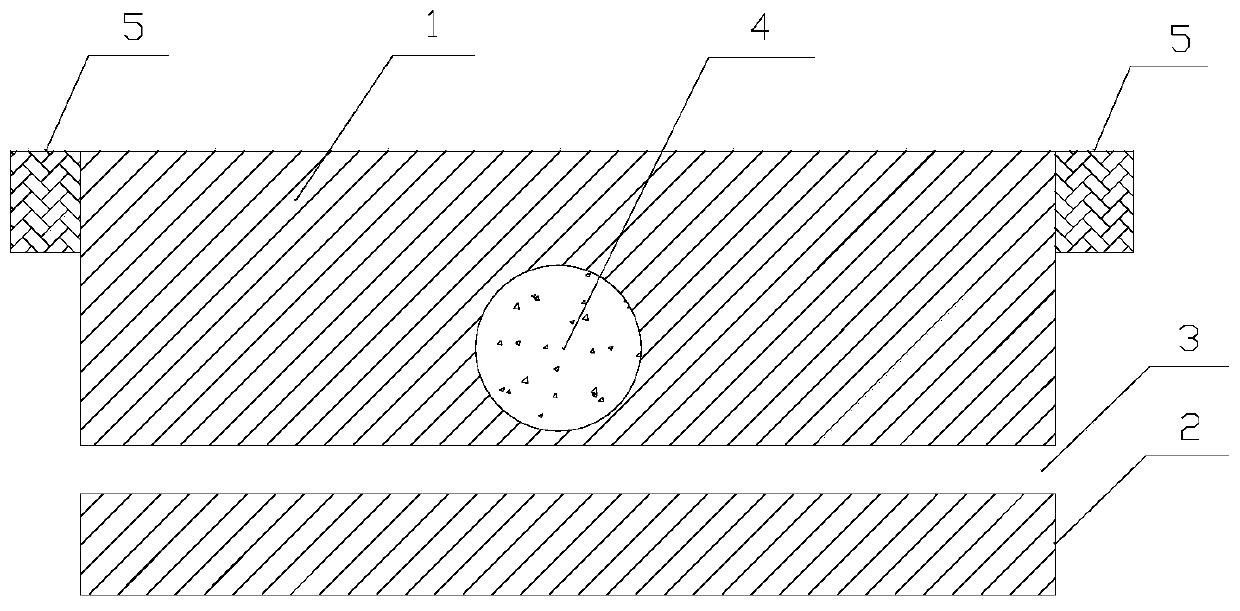

[0022] On the basis of Example 1, such as figure 2 As shown, the electrodes 5 are connected to both ends of the first metal plate 1 . The first metal plate 1 is used as the carrier of the current to be measured. The cavity 4 is circular, and the distance between the cavity 4 and the slit 3 is less than 100 nanometers, so that the surface plasmon polaritons in the slit 3 are coupled into the cavity 4 . The distance from the cavity 4 to the side of the first metal plate 1 away from the slit 3 is greater than 100 nanometers and less than 400 nanometers, that is to say, the distance between the cavity 4 figure 2 The distance between the tops of the first metal plate 1 is greater than 100 nanometers and less than 400 nanometers. It is designed so that the current to be measured not only flows from the area between the cavity 4 and the slit 3, but also flows from the area from the cavity 4 to the top of the first metal plate 1, and the direction of the current flowing from the t...

Embodiment 3

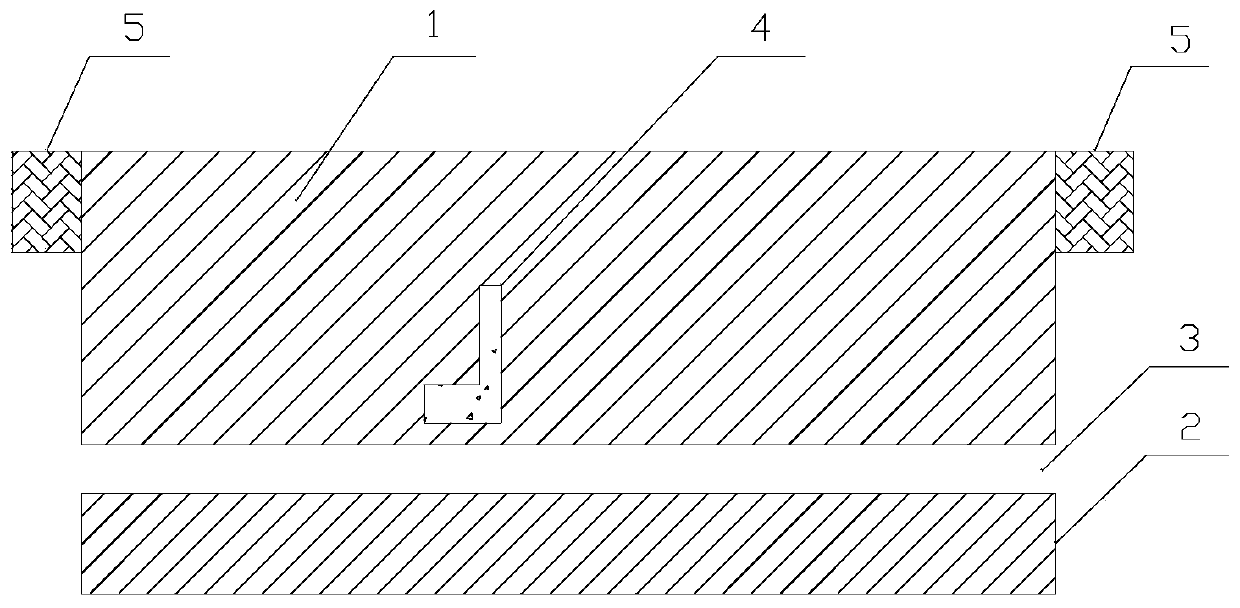

[0024] On the basis of Example 2, such as image 3 As shown, the cavity 4 is L-shaped. The cavity 4 can also be U-shaped, V-shaped and other shapes. When the cavity 4 has these shapes, the currents near the cavity 4 are different, the excited magnetic fields are different, and the changes to the refractive index of the magnetic fluid are different, resulting in serious non-uniform distribution of the refractive index in the cavity 4 . The resonance peak of the cavity is split and the resonance peak is narrower, which improves the detection sensitivity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com