Metal additive forming fusion depth real-time prediction method based on depth and transfer learning

A transfer learning and metal additive technology, which is applied in the field of real-time prediction of metal additive forming penetration based on depth and transfer learning, can solve problems such as large errors in prediction values, image data interference, and low accuracy, so as to improve efficiency and improve The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

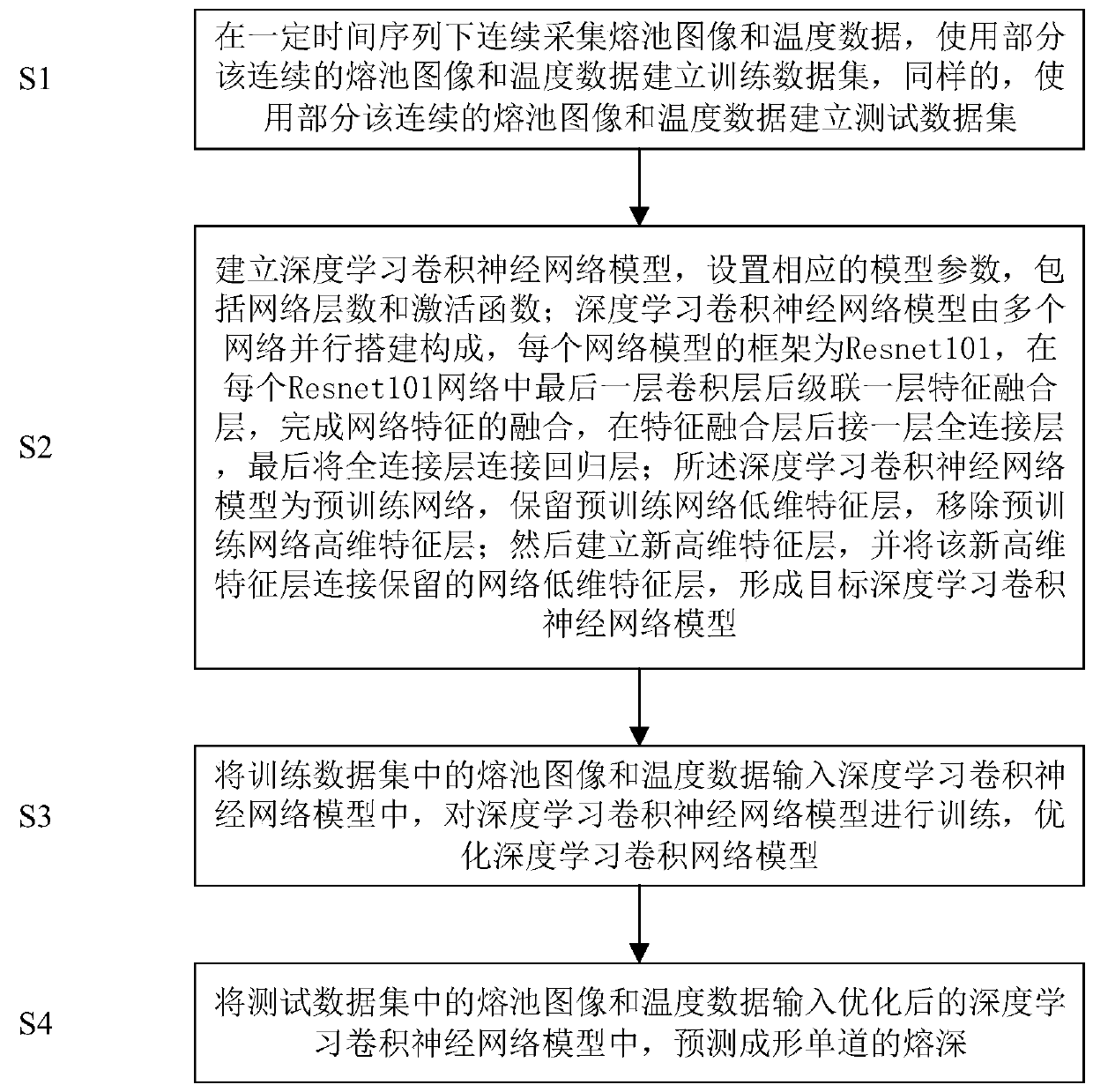

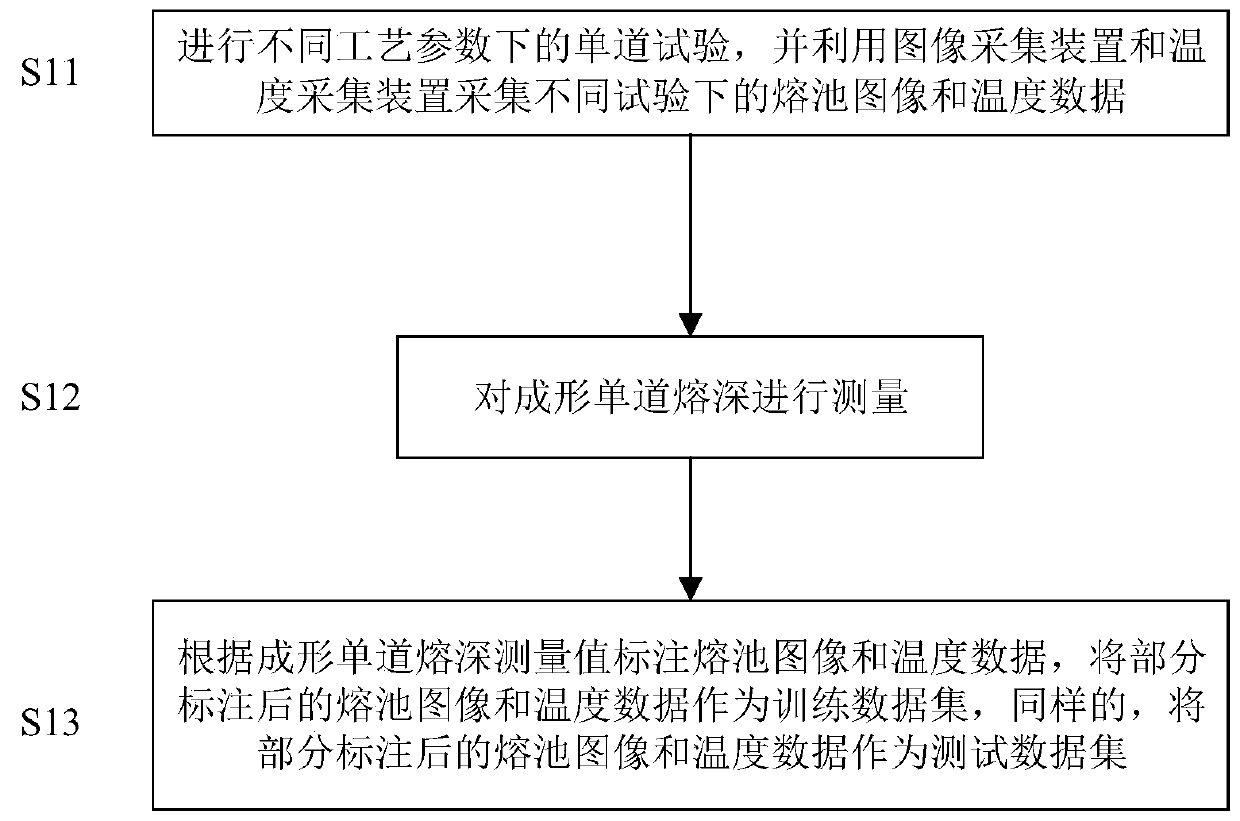

[0036] Such as figure 1 and Figure 4 As shown, the real-time prediction method of metal additive forming penetration depth based on depth and transfer learning includes the following steps:

[0037] S1: Continuously collect molten pool images and temperature data in a certain time series, and perform feature fusion processing on the molten pool images and temperature data, and use part of the continuous molten pool images and temperature data that have undergone feature fusion processing to establish a training data set. Similarly, use the continuous melt pool image and temperature data partially processed by feature fusion to establish a test data set;

[0038] S2: Establish a deep learning convolutional neural network model, set the corresponding model parameters, including the number of network layers and activation functions; the deep learning convolutional neural network model is composed of multiple networks built in parallel, and the framework of each network model is...

Embodiment 2

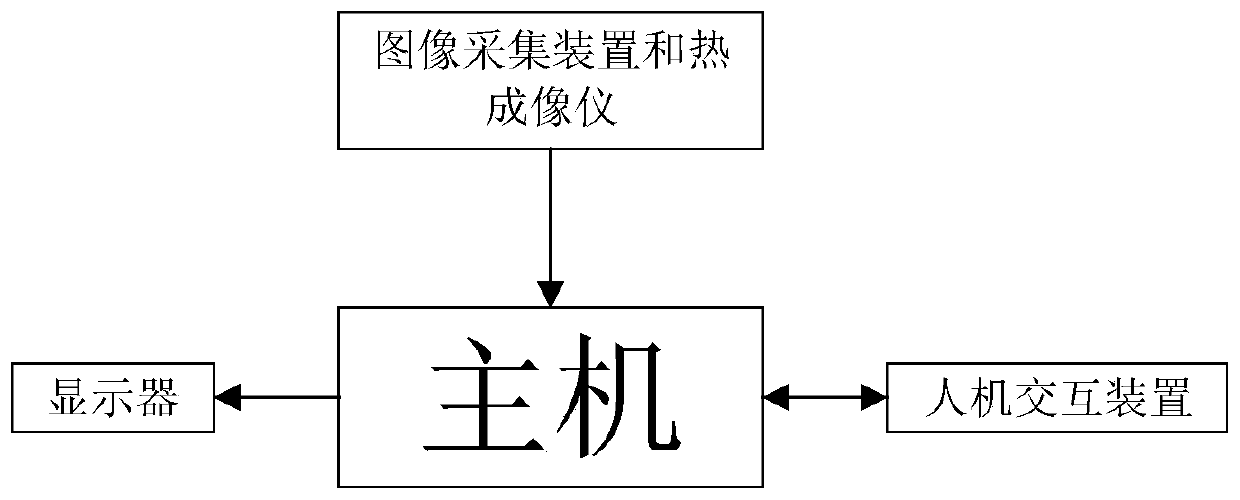

[0054] Such as image 3 As shown, the real-time prediction of metal additive forming penetration based on depth and transfer learning includes a printing workbench, an image acquisition device and a temperature acquisition device, a human-computer interaction device, a display and a host, the image acquisition device and a temperature acquisition device, Both the human-computer interaction device and the display are electrically connected to the host, and the image acquisition device and temperature acquisition device are installed above the printing workbench; the image acquisition device is used to continuously collect the melting pool in a certain time sequence image and transmit the collected melt pool image to the host; the temperature acquisition device is used to continuously collect temperature data in a certain time sequence and transmit the collected temperature data to the host; the host is used to use Part of the continuous molten pool image and temperature data is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com