Inspection system and method for semiconductor integrated circuit device

A technology of integrated circuits and inspection systems, applied in the direction of circuits, semiconductor/solid-state device testing/measurement, electrical components, etc., to achieve the effects of production improvement, production process improvement, and production quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

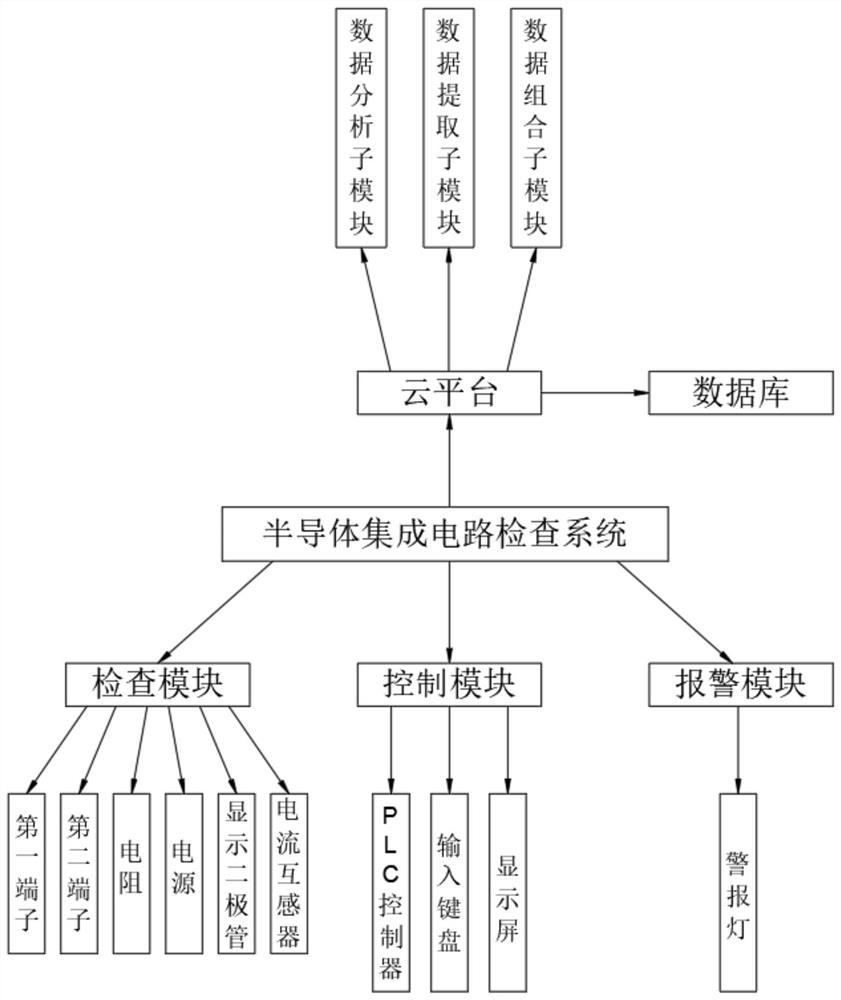

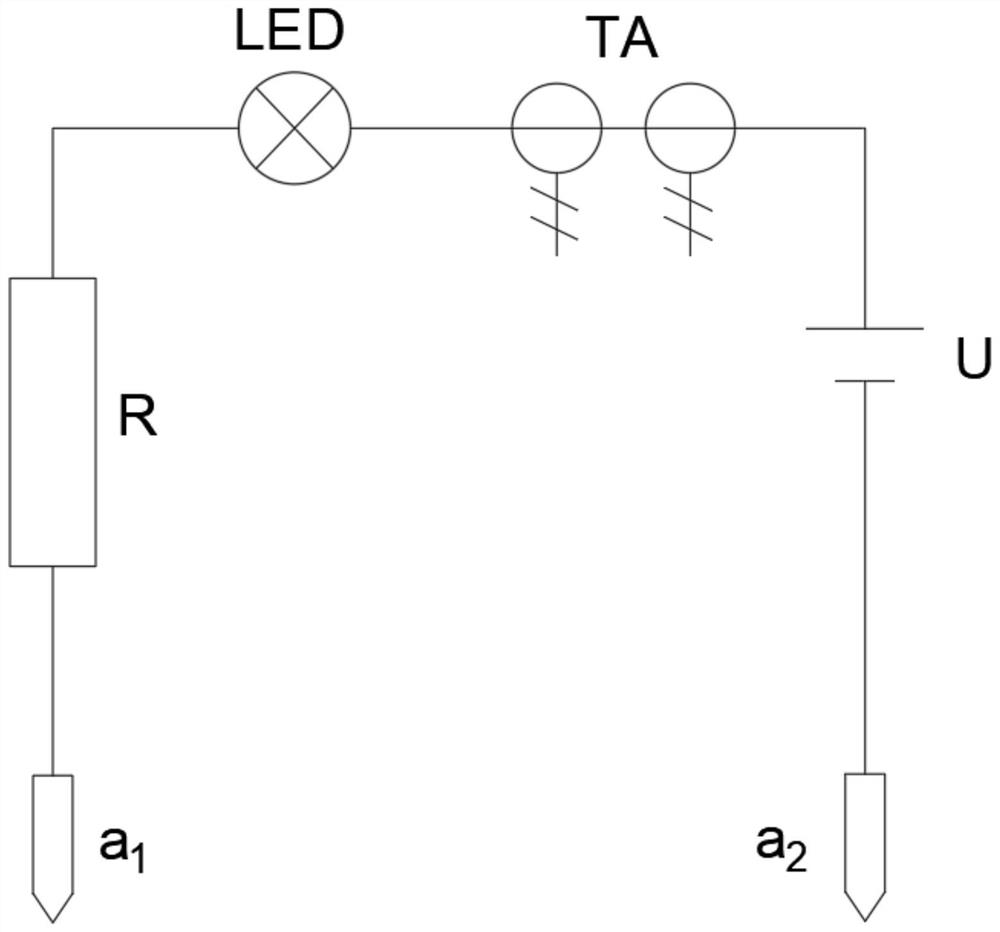

[0044] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, an inspection system for semiconductor integrated circuit devices, the inspection system includes an inspection module, a control module, an alarm module and a cloud platform;

[0045]The output terminal of the inspection module is electrically connected to the input terminal of the control module, and the output terminal of the control module is electrically connected to the input terminal of the alarm module and the cloud platform;

[0046] Inspection module: used to check whether the welding pins of semiconductor integrated circuits have virtual welding;

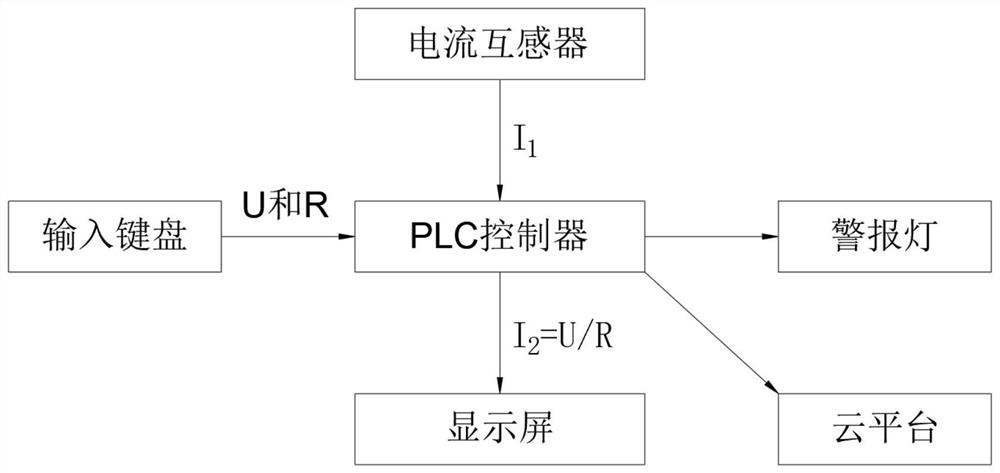

[0047] Control module: used to intelligently control the entire system, and also used to visually display the inspection results;

[0048] Alarm module: used to alarm when there is a false soldering phenomenon in the inspection of the semiconductor integrated circuit;

[0049] Cloud platform: used to store and analyze insp...

Embodiment 1

[0088] Embodiment 1: Use the input keyboard to input the voltage value of 4.8V, the resistance value of 22Ω and the resistance value of the display diode into the PLC controller, according to Ohm's law:

[0089]

[0090] Calculate the expected current value I in the inspection module circuit 1 =0.5A;

[0091] Utilize the current transformer to check the real-time current I2=0A of the module circuit;

[0092] I 1 ≠ I 2 , indicating that the soldering of electronic components of semiconductor integrated circuits has a virtual soldering phenomenon.

Embodiment 2

[0093] Embodiment 2: Use the input keyboard to input the voltage value of 4.8V, the resistance value of 22Ω and the resistance value of the display diode into the PLC controller by using the input keyboard. According to Ohm's law:

[0094]

[0095] Calculate the expected current value I in the inspection module circuit 1 =0.5A;

[0096] Use the current transformer pair to check the real-time current I of the module circuit 2 =0.5A;

[0097] I 1 = I 2 , indicating that the soldering of electronic components of semiconductor integrated circuits is in a normal state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com