Mint essence for heat-not-burning cigarette, tobacco sheet and heat-not-burning cigarette

A heat-not-burn and mint flavor technology, which is applied in tobacco, processed tobacco, essential oils/flavors, etc., can solve problems such as not being able to obtain the cooling sensation of mint, polluting the working environment and production lines, and having a weak mint flavor, etc. Achieve the effects of improving and modifying aroma, coordinating smoke aroma, and improving aroma quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

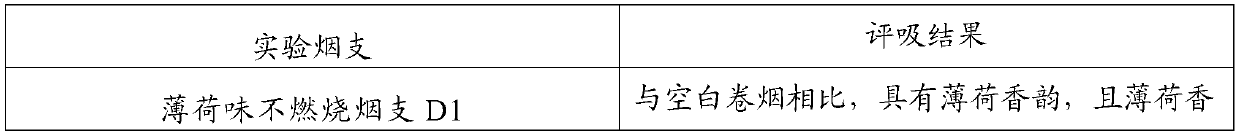

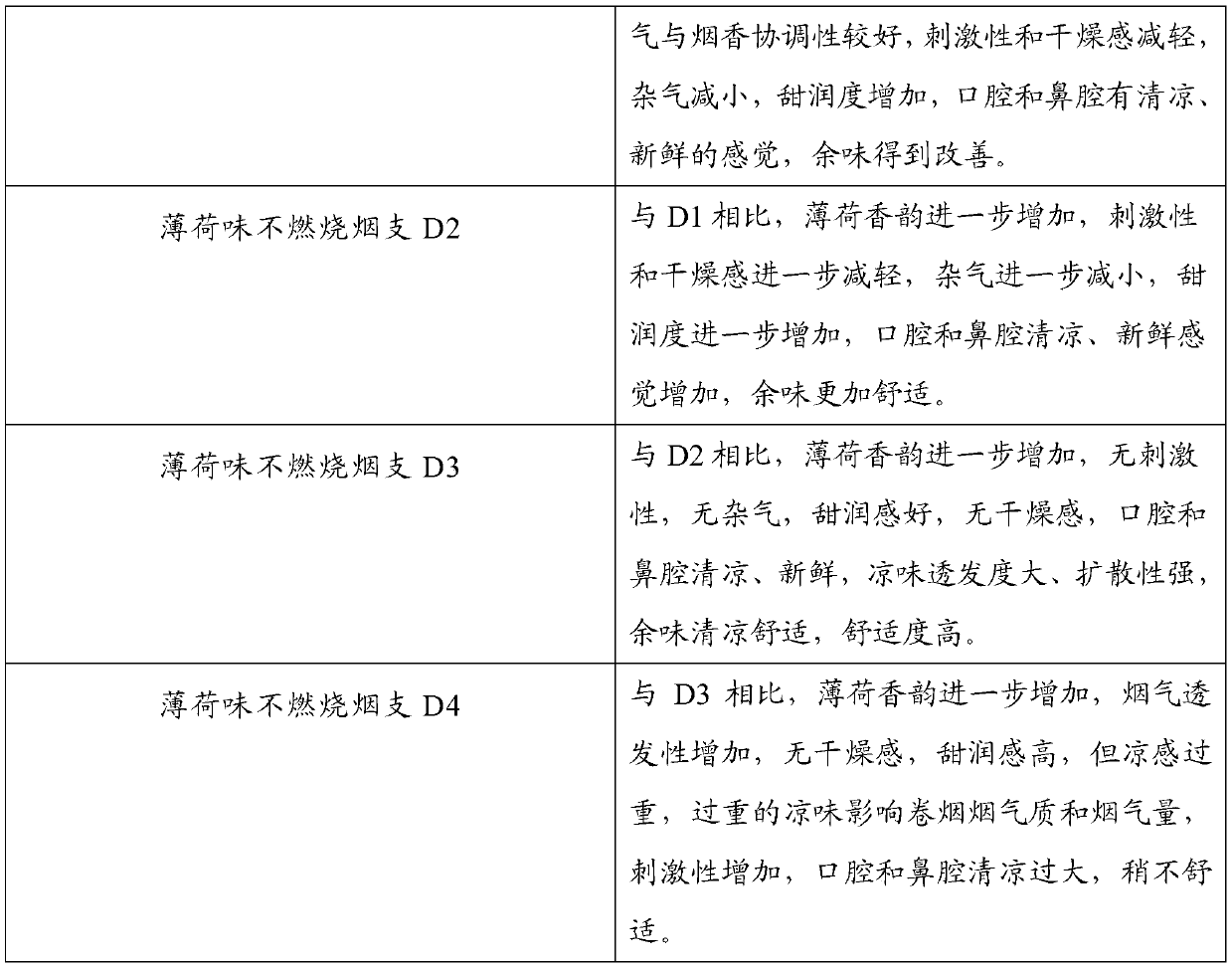

Embodiment 1

[0050] Add 20g of menthyl nylonate, 8g of monomenthyl succinate and 16g of menthyl lactate into 909g of propylene glycol, and stir well to obtain a mint base; weigh 15g of lemon oil, 2g of cinnamon oil, and 6g of bitter wood bark oil , clove oil 4g, rose oil 5g, dihydrocoumarin 1g, jasmonal 1g, vanillin 3g and tonka bean extract 6g, fully oscillate, mix and dissolve to prepare auxiliary fragrance base; prepare mint fragrance base After being mixed with the auxiliary fragrance base, fully shaken, the mint flavor S1 for heat-not-burn cigarettes can be obtained.

[0051] After adding 5wt% mint essence S1 to the tobacco sheet, the tobacco sheet is made into a mint-flavored non-burning cigarette D1.

Embodiment 2

[0053] Add 30g of menthyl nylonate, 12g of monomenthyl succinate and 20g of menthyl lactate into 870g of propylene glycol, and stir well to obtain a mint base; weigh 20g of lemon oil, 4g of cinnamon oil, and 8g of bitter wood bark oil , clove oil 6g, rose oil 6g, dihydrocoumarin 4g, jasmonal 2g, vanillin 4g and tonka bean extract 10g, fully oscillate, mix and dissolve to prepare auxiliary fragrance base; prepare mint fragrance base After being mixed with the auxiliary fragrance base, the mixture is fully shaken to obtain mint flavor S2 for heat-not-burn cigarettes.

[0054] After adding 8wt% mint essence S2 to the tobacco sheet, the tobacco sheet is made into a mint-flavored non-burning cigarette D2.

Embodiment 3

[0056] Add 35g of menthyl nylonate, 16g of monomenthyl succinate and 25g of menthyl lactate into 844g of propylene glycol, and stir well to obtain a mint base; weigh 22g of lemon oil, 5g of cinnamon oil, and 10g of bitter wood bark oil , clove oil 7g, rose oil 8g, dihydrocoumarin 5g, jasmonal 3g, vanillin 4g and tonka bean extract 12g, fully oscillating, mixing and dissolving to obtain an auxiliary fragrance base; prepare the mint fragrance base After being mixed with the auxiliary fragrance base, fully shaken, the mint flavor S3 for heat-not-burn cigarettes is obtained.

[0057] After adding 6wt% mint essence S3 to the tobacco sheet, the tobacco sheet is made into a mint-flavored non-burning cigarette D3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com