Drying cylinder stripping agent for papermaking and preparation method thereof

A drying cylinder peeling and oily agent technology, applied in the direction of coating, wax coating, etc., can solve the problems of reduced water absorption ability, oil quality, and poor use effect, and achieve good dispersion, good mechanical stability, The effect of solving the problem of cylinder sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

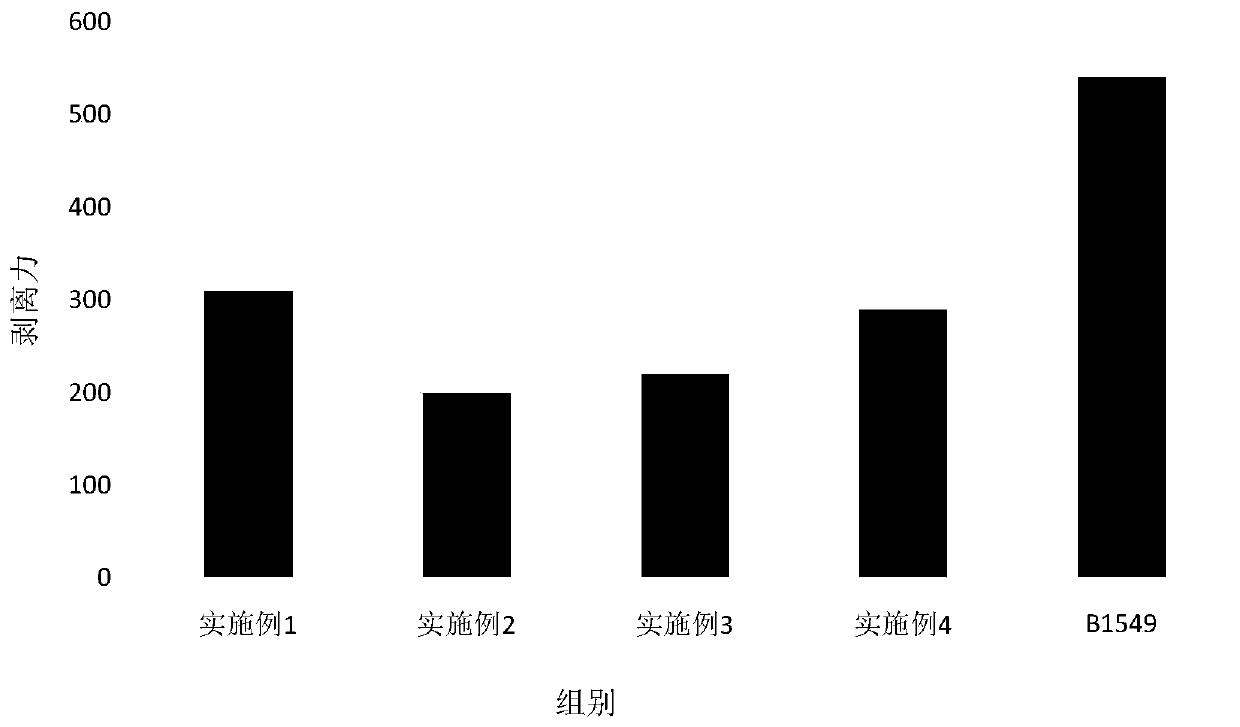

Examples

Embodiment 1

[0023] Put 500 parts (parts by weight, the same below) of 26# white oil into a dry and clean 1000L high-speed mixer, keep the speed at 1000 rpm, then add 200 parts of tall oil fatty acid and 100 parts of tall oil to the high-speed mixer ; Stir for 10 minutes. Add 80 parts of Span 80 and Tween 80 to the above system, and stir for 15 minutes. Finally, 20 parts of polyethylene glycol 600 was added and stirred for 5 minutes. Then add 100 parts of polyethylene glycol 400 dioleate and stir for 10 minutes. After the sampling test is qualified, the material is discharged and packaged.

Embodiment 2

[0025] Put 200 parts of 32# white oil into a dry and clean 1000L high-speed mixer, keep the speed at 1000 rpm, then add 150 parts of tall oil fatty acid and 50 parts of tall oil to the high-speed mixer, and stir for 20 minutes. Add 400 parts of alkylphenol polyoxyethylene ether (10) and Tween 80 to the above system, and stir for 15 minutes. Finally, 100 parts of polyethylene glycol 400 was added and stirred for 5 minutes. Then add 100 parts of polyethylene glycol 400 monooleate and stir for 10 minutes. After the sampling test is qualified, the material is discharged and packaged.

Embodiment 3

[0027] Put 400 parts of 32# white oil into a dry and clean 1000L high-speed mixer, keep the speed at 1000 rpm, then add 400 parts of oleic acid hydroxyethylimidazoline into the high-speed mixer, and stir for 15 minutes. Add 180 parts of polyethylene glycol 400 monooleate and alkylphenol polyoxyethylene ether (10) to the above system, and stir for 10 minutes. Finally 20 parts of polyethylene glycol 400 was added and stirred for 15 minutes. After the sampling test is qualified, the material is discharged and packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com