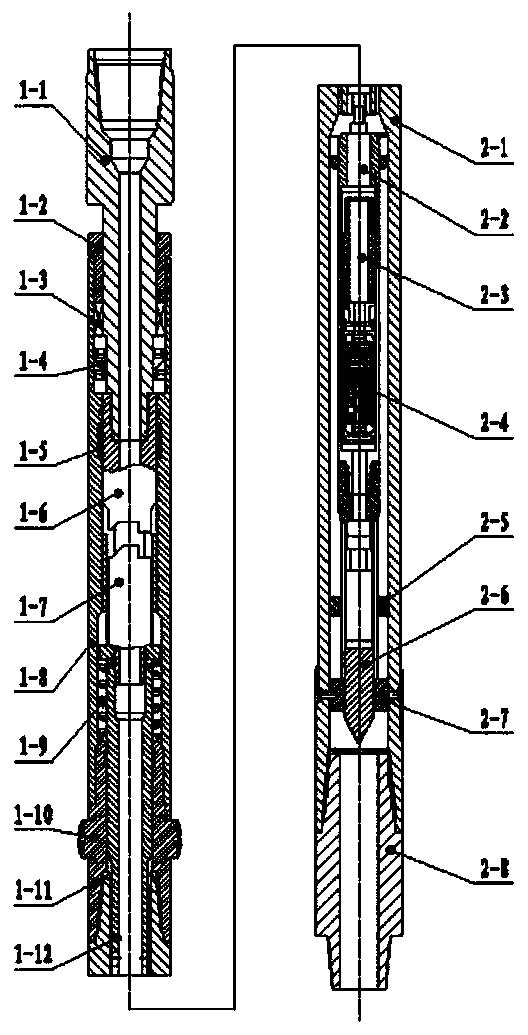

Half-way rotary well track control tool

A technology for wellbore trajectory and control tools, applied in the automatic control system of drilling, drilling equipment, directional drilling, etc., can solve the problems of low ROP, difficult orientation in directional sections, etc., achieve low cost and improve wellbore cleaning ability , the effect of good economical applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

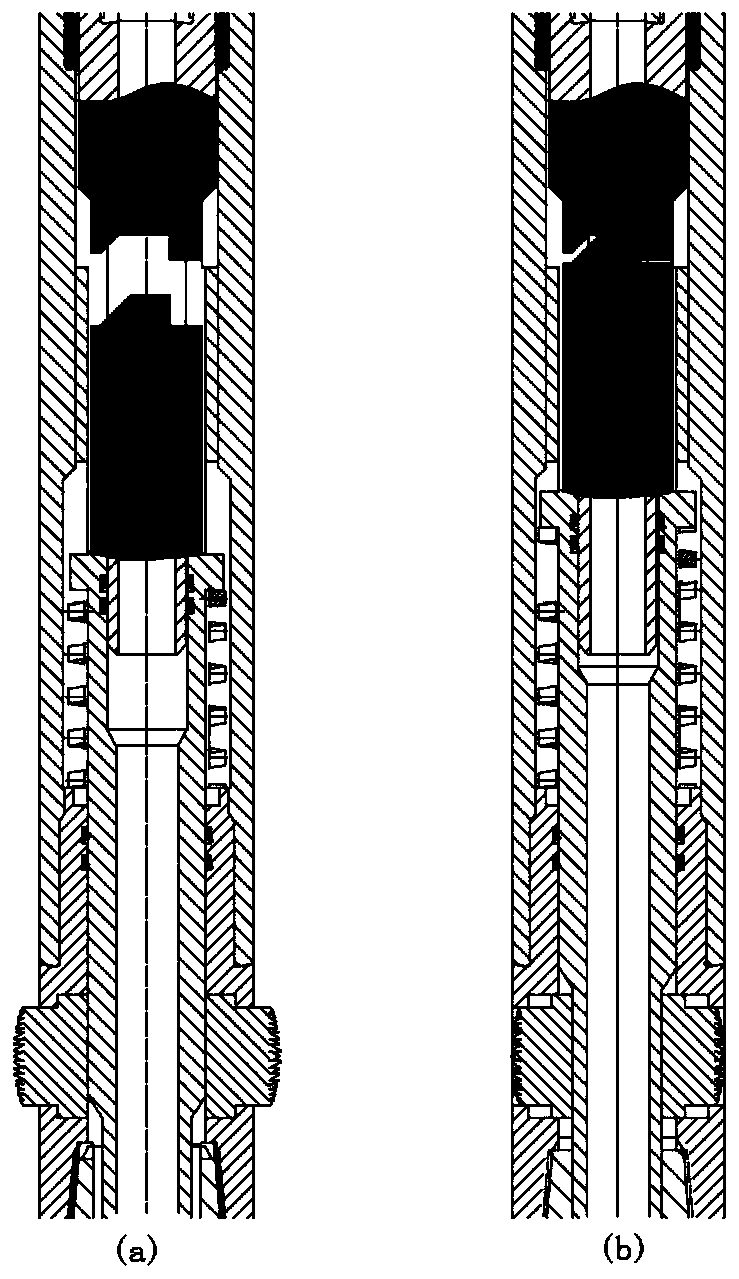

[0031] An 8 1 / 2″ wellbore uses a downhole motorized drilling tool assembly for conventional sliding directional drilling in the horizontal section, and the half-rotary well trajectory control tool is installed in the drill string at a certain distance from the rear end of the downhole motor. The surface Send out a set of bypass valve shunt and pressure relief signals at a certain time interval, and transmit them to the half-rotary wellbore trajectory control tool. The pressure sensor built in the downhole electronic control unit of the tool will drive the DC motor after receiving the pressure change signal 2-3 Make an action to drive the center rod 1-12 to move up. The upper half clutch 1-6 and the lower half clutch 1-7 leave to realize the pipe string turning up and down. At this time, the turntable can rotate normally at a certain speed, and the driller has a small drilling pressure. Send the drill and observe whether the tool face is stable. If the tool face is relatively st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com