Stator excitation flywheel pulse reluctance generator system

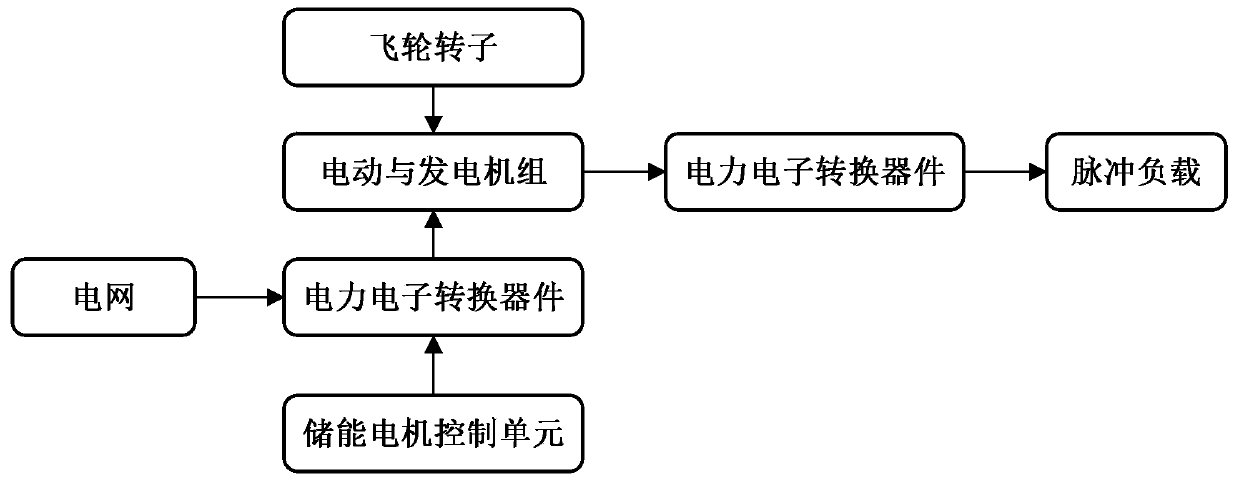

A reluctance motor and generator technology, applied in synchronous generators, electrical components, electromechanical devices, etc., can solve the problems of low power density, low energy density, large volume and weight, etc., and achieve high power density and energy density. Small and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

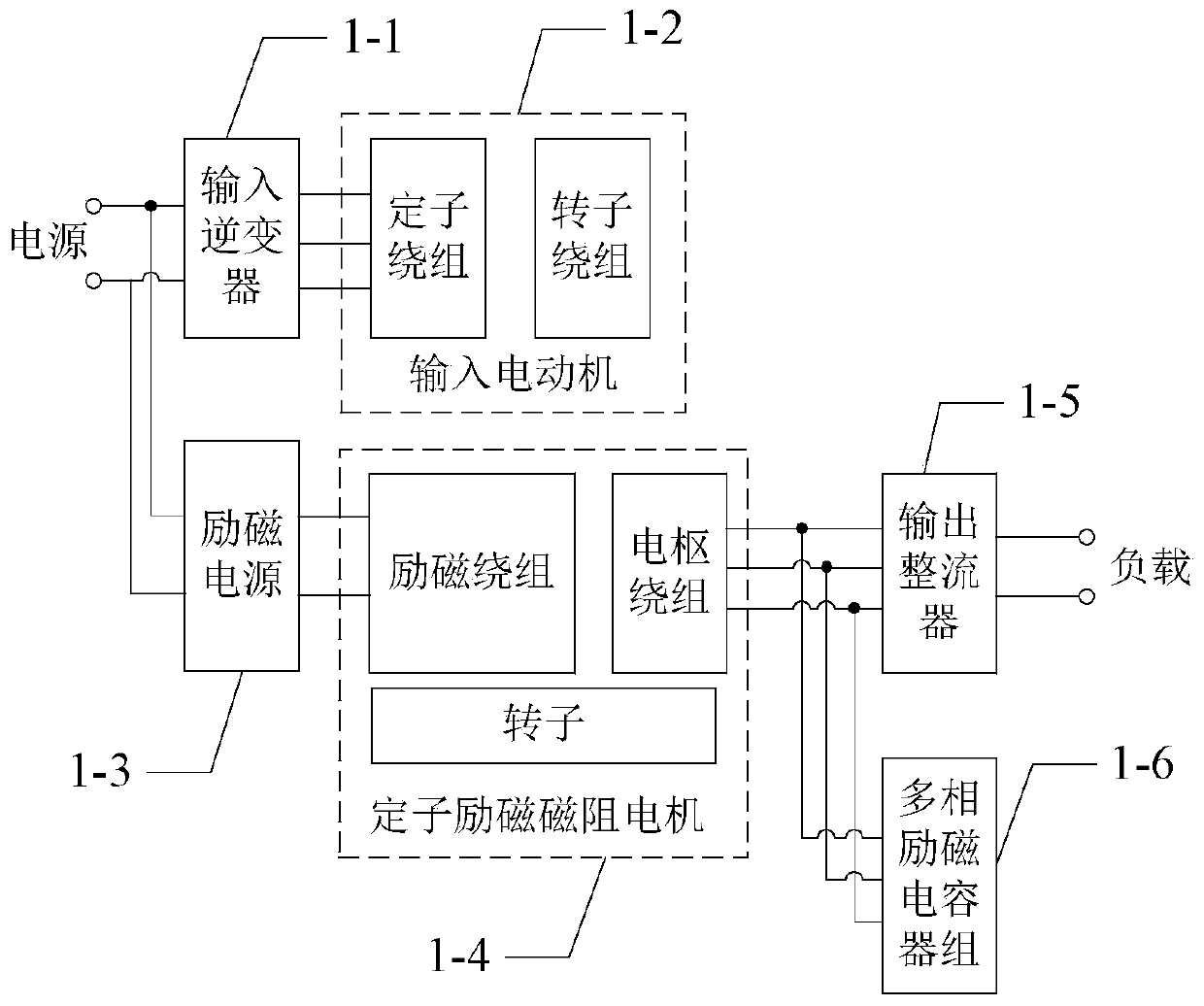

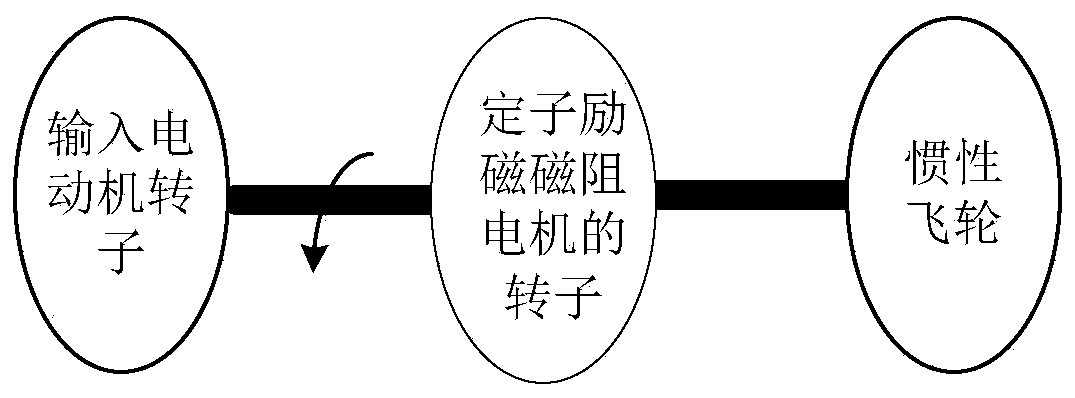

[0025] Specific implementation mode one: combine figure 2 and image 3 Describe this embodiment, a stator excitation flywheel pulse reluctance generator system described in this embodiment includes an input inverter 1-1, an input motor 1-2, an excitation power supply 1-3, a stator excitation reluctance motor 1- 4. Output rectifier 1-5, multi-phase excitation capacitor bank 1-6 and inertial flywheel;

[0026] The output end of the input inverter 1-1 is connected to the lead wire of the stator winding of the input motor 1-2; the output end of the excitation power supply 1-3 is connected to the lead wire of the excitation winding of the stator excitation reluctance motor 1-4, The lead wires of the multiphase armature windings of the stator excitation reluctance motor 1-4 are connected to the AC input terminals of the output rectifier 1-5, and the output terminals of the multiphase armature windings of the stator excitation reluctance motor 1-4 are connected in parallel with the...

specific Embodiment approach 2

[0028] Specific implementation mode two: combination image 3 and Figure 4 Describe this embodiment, a stator excitation flywheel pulse reluctance generator system described in this embodiment includes an input inverter 2-1, an input motor 2-2, an excitation power supply 2-3, a stator excitation reluctance motor 2- 4. Output rectifier 2-5, multi-phase excitation capacitor bank 2-6 and inertial flywheel;

[0029] The output end of the input inverter 2-1 is connected with the lead-out wire of the stator winding of the input motor 2-2; the output end of the excitation power supply 2-3 is connected with the lead-out wire of the excitation winding of the stator excitation reluctance motor 2-4, The two output terminals of each phase of the armature winding of the excitation reluctance motor 2-4 are respectively connected with the two AC input terminals of a single-phase rectifier 2-5, and at the same time, each phase of the stator excitation reluctance motor 2-4 The two output en...

specific Embodiment approach 3

[0031] Specific implementation mode three: combination Figure 5 and Figure 6 Describe this embodiment, a stator excitation flywheel pulse reluctance generator system described in this embodiment includes an input inverter 3-1, an input permanent magnet AC motor 3-2, a stator excitation reluctance motor 3-3, an output Rectifier 3-4, multi-phase excitation capacitor bank 3-5 and inertial flywheel;

[0032] The output terminal of the input inverter 3-1 is connected to the lead-out line of the stator winding of the input permanent magnet AC motor 3-2; the positive and negative pole output terminals of the DC bus of the input inverter 3-1 are connected to the stator excitation reluctance motor 3-3 The lead wires of the excitation winding of the stator excitation reluctance motor 3-3 are connected together, the lead wires of the multiphase armature winding of the stator excitation reluctance motor 3-3 are connected with the AC input end of the output rectifier 3-4, and the multip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com