Roller way positioning method for preventing roller way slide carriage

A positioning method and roller table technology, applied in electrical components, control systems, AC motor control, etc., can solve problems such as affecting the quality of steel plates, wrong marking positions, uneven roller planes, etc., to increase benefits, prevent slippage, The effect of improving the quality of the steel plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

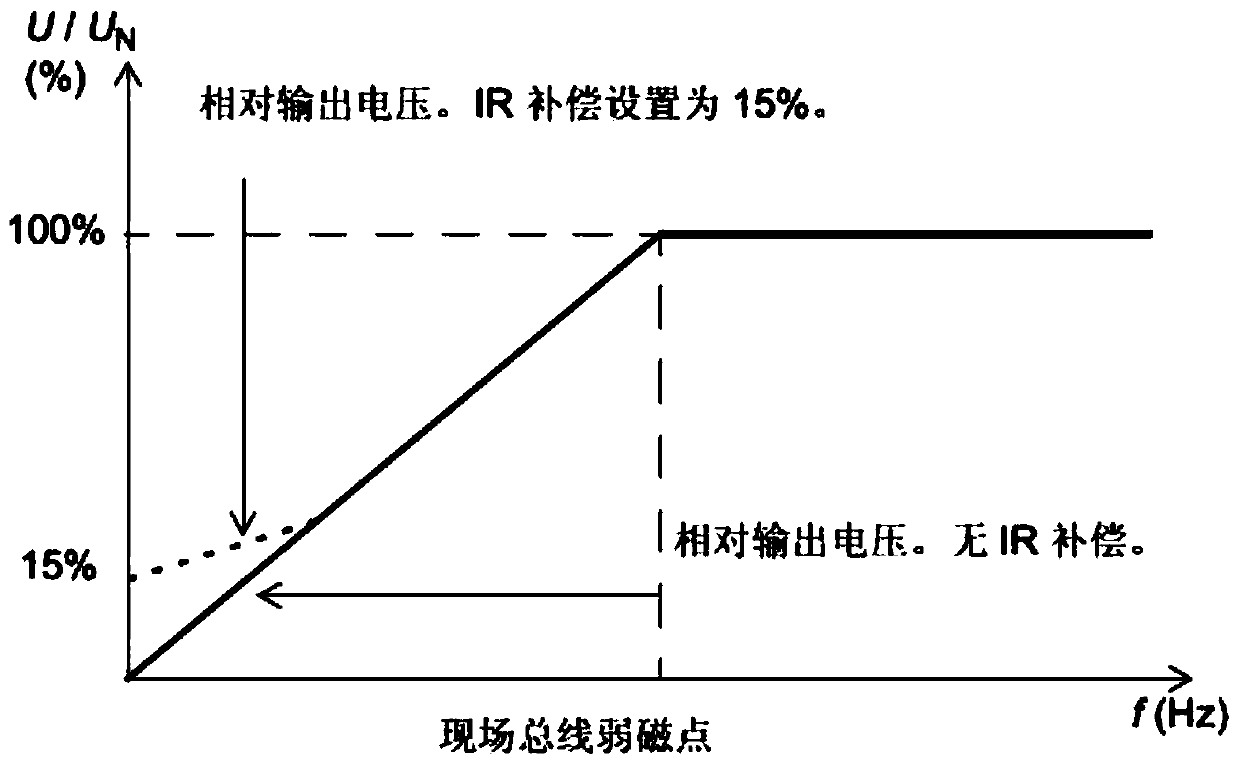

[0012] This embodiment provides a method for positioning rollers to prevent roller slides, involving the IR compensation function of ABB ACS800 multi-transmission inverters, such as figure 1 Shown, including

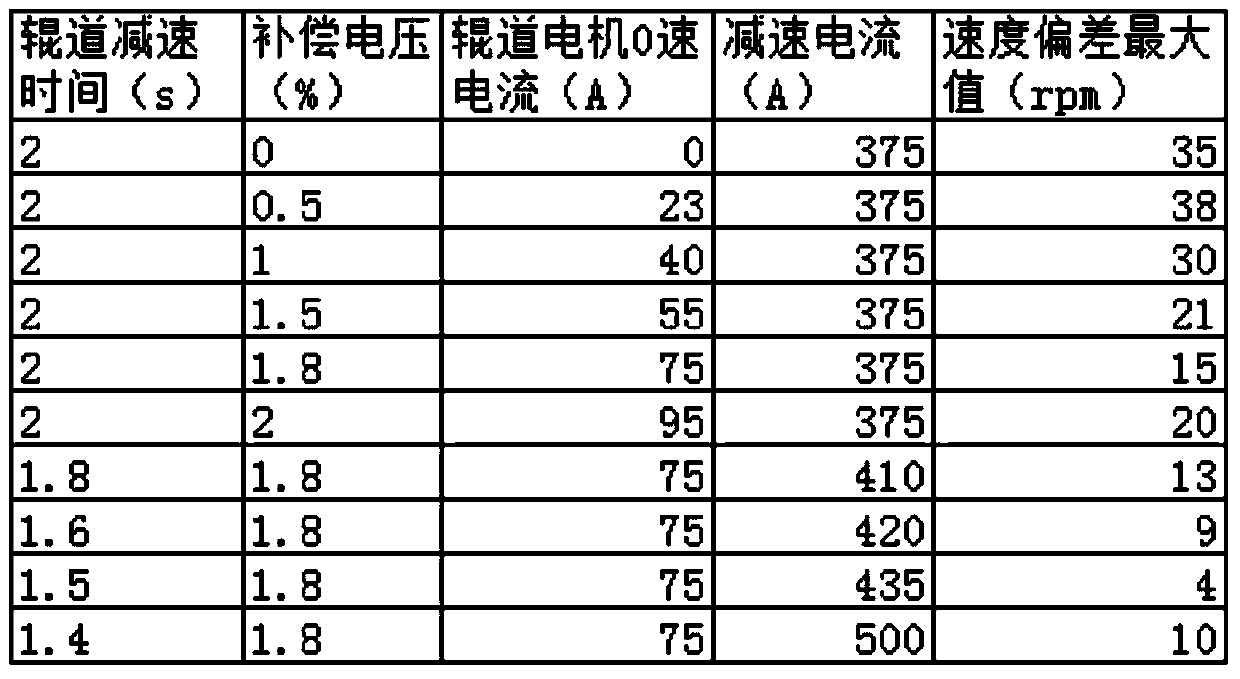

[0013] Inverter IR compensation is 0 speed compensation: when the motor is at 0 speed, the motor's magnetic flux is adjusted by supplying the motor's output voltage of 5%-10% of the rated voltage to meet the application of 0 speed and high starting torque; After the steel plate reaches the specified position, it stops at 0 speed. In the case of uninterrupted power supply, the inverter provides a compensation voltage of 5%-10% relative to the rated voltage for the motor to increase the motor flux and excitation current to ensure 0 speed torque; tracking model optimization: the deceleration time is the time it takes for the motor to decelerate from the highest speed to 0 speed. Theoretically, the shorter the deceleration time, the better, but the shorter the time, the greater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com