A high-speed electromagnetic polishing device for complex curved surfaces with small and medium diameters

A technology of complex curved surfaces and polishing devices, applied in grinding/polishing equipment, optical surface grinders, manufacturing tools, etc., can solve problems such as reducing optical processing efficiency, and achieve the effect of improving optical processing efficiency, compression time, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0030] In order to effectively shorten the optical modification time and improve the optical processing efficiency, the present invention designs an electromagnetic high-speed polishing device based on magnetorheological fluid to process complex curved optical elements with small and medium calibers.

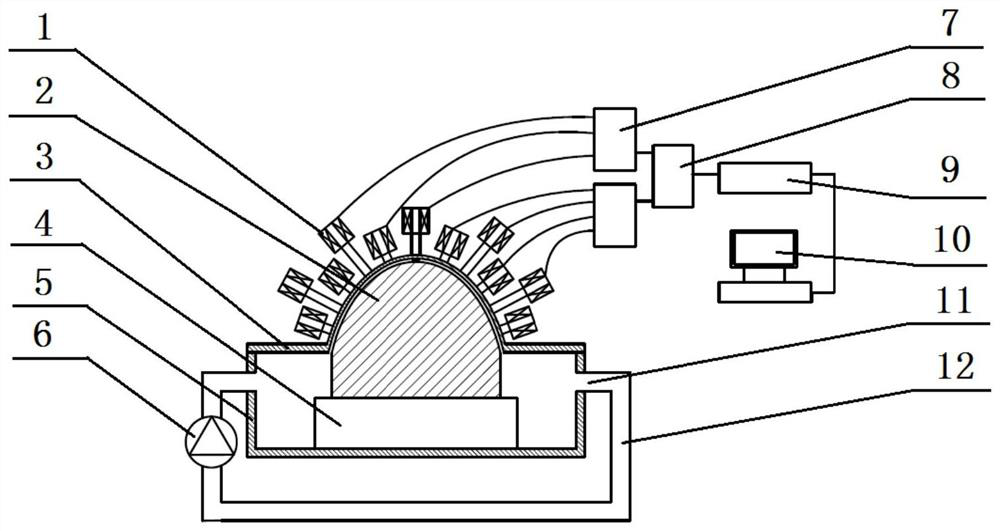

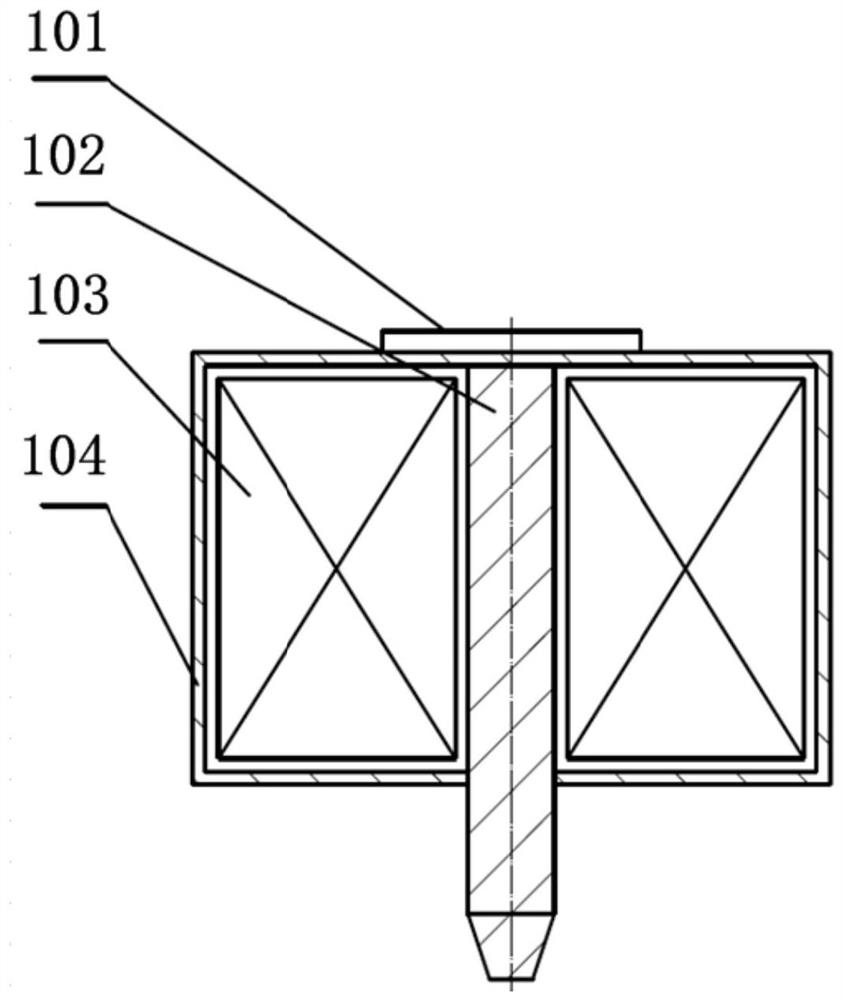

[0031] figure 1 It is a structural schematic diagram of a high-speed electromagnetic polishing device for complex curved surfaces with small and medium calibers according to the present invention. As shown in the figure, the device includes a sealed container, an object stage 4, a magnetorheological fluid circulation pipeline 12 and a controllable magnetic field generating device.

[0032] The airtight container is composed of a container body 5 and an upper cover 3 . Both the container body 5 and the upper cover 3 are made of non-magnetic material, prefer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com