Modified welan gum, preparation method thereof, water-based fracturing fluid composition and water-based fracturing fluid

A technology of water-based fracturing and Welan gum, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problem of no cross-linking-viscosification system, slow dissolution of Welan gum, and gel-forming properties Poor problems, to achieve the effect of low cost, increased viscosity, enhanced viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

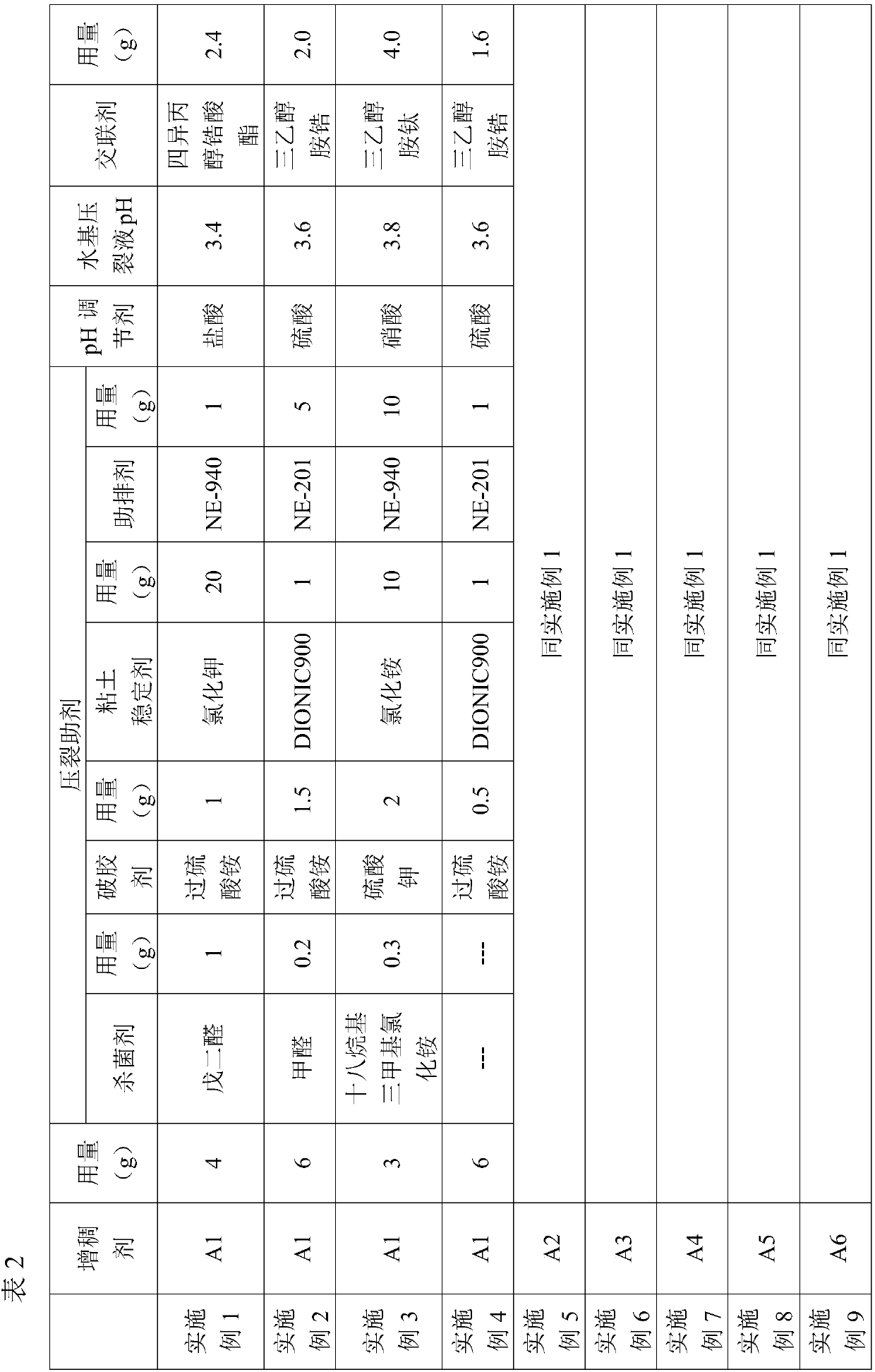

[0016] According to the first aspect of the present invention, there is provided a preparation method of modified Welan gum, the method comprising: in the presence of an organic solvent and a phase transfer catalyst, contacting Welan gum with citric acid to obtain citric acid modified Sexual Welan gum.

[0017] According to the present invention, the phase transfer catalyst can be various conventional phase transfer catalysts in the art, preferably a quaternary ammonium salt phase transfer catalyst, such as but not limited to benzyltriethylammonium chloride, tetraethylammonium chloride , Tetrabutylammonium Bromide, Tetrabutylammonium Chloride, Tetrabutylammonium Bisulfate, Trioctylmethylammonium Chloride, Dodecyltrimethylammonium Chloride, Tetradecyltrimethylammonium Chloride at least one of ammonium chloride and trimethyloctadecylammonium chloride. Preferably, the phase transfer catalyst is trimethyloctadecylammonium chloride.

[0018] Wherein, the amount ratio of the Welan...

preparation example 1

[0055] This preparation example is used to illustrate the preparation of citric acid modified Welan gum

[0056] In a three-necked flask, take 5g of Welan gum and 5g of trimethyloctadecylammonium chloride and mix them in 80ml of toluene under stirring conditions to prepare a suspension of 62.5g / L. Add 1.39g of citric acid Add the crystals into the above suspension at a substantially constant speed within 30 minutes, stir at a speed of 450rpm to fully dissolve it; react at normal pressure, 90°C, and 500rpm for 10 hours, take out the reaction solution, and pour it into The product was precipitated in a large amount of absolute ethanol, washed, filtered with suction, and dried at 60°C for 24 hours to obtain the modified Velan gum product A1. The water solubility and viscosity are shown in Table 1.

preparation example 2

[0058] This preparation example is used to illustrate the preparation of citric acid modified Welan gum

[0059] In a three-necked flask, mix 5g of Welan gum and 7.5g of trimethyloctadecylammonium chloride in 83ml of toluene under stirring conditions, and prepare a suspension of about 60g / L. Mix 2.5g of lemon The acid crystals were added to the above-mentioned suspension at a substantially constant speed within 20 minutes, stirred at a speed of 500 rpm to allow it to fully dissolve; reacted at normal pressure, 110°C, and 550 rpm for 9 hours, took out the reaction solution, and poured Add a large amount of absolute ethanol to precipitate the product, wash, filter with suction, and dry at 70°C for 12 hours to obtain the modified Velan gum product A2. See Table 1 for water solubility and viscosity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com