Penicillium oxalicum capable of degrading organic acid smelly matter and scale-up cultivation method and application of Penicillium oxalicum

A technology of Penicillium oxalate and enlarged culture, applied in the field of Penicillium oxalate and its enlarged culture, can solve the problems of limited deodorization effect of livestock manure and the like, and achieve the effects of easy growth, strong growth adaptability and high tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

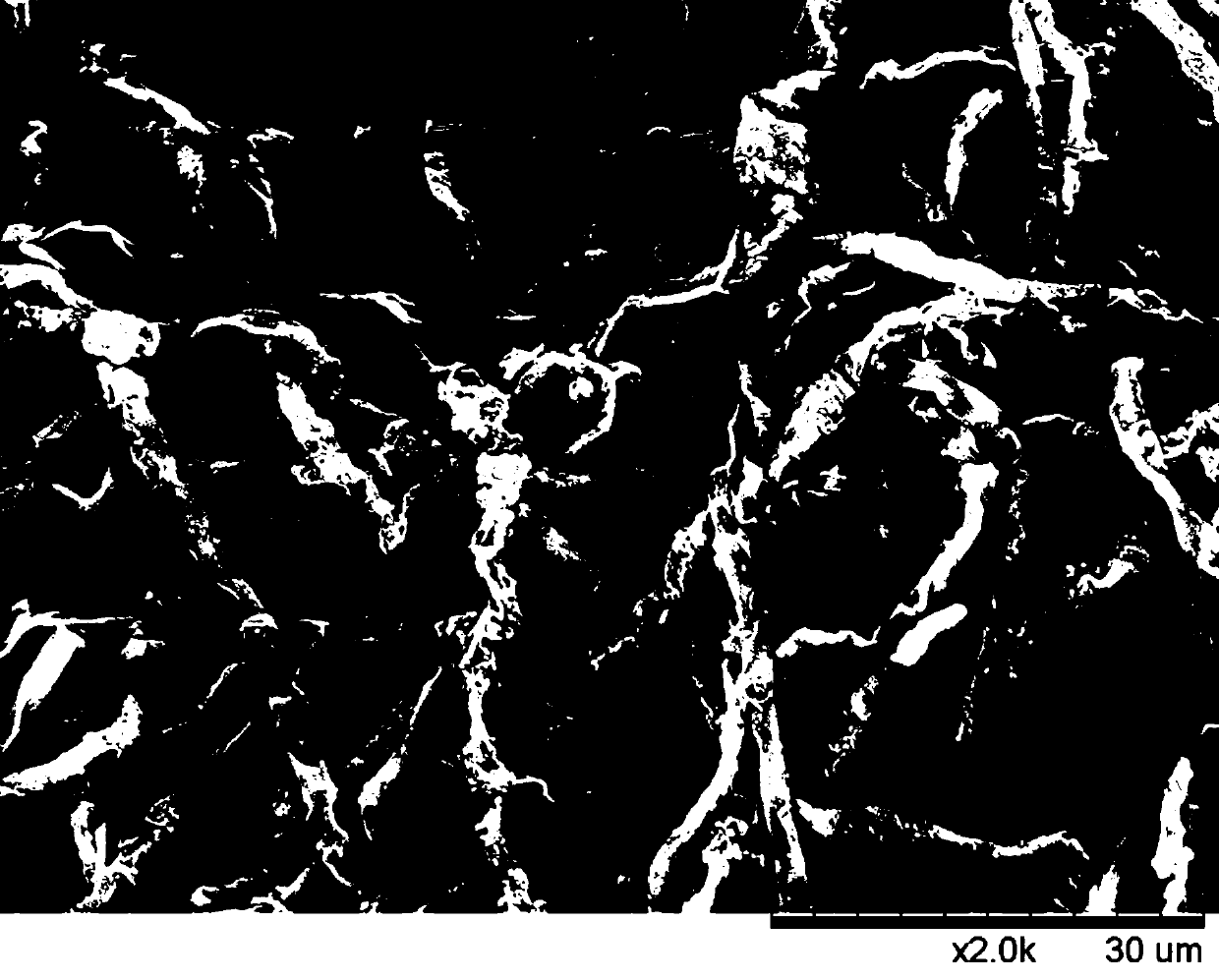

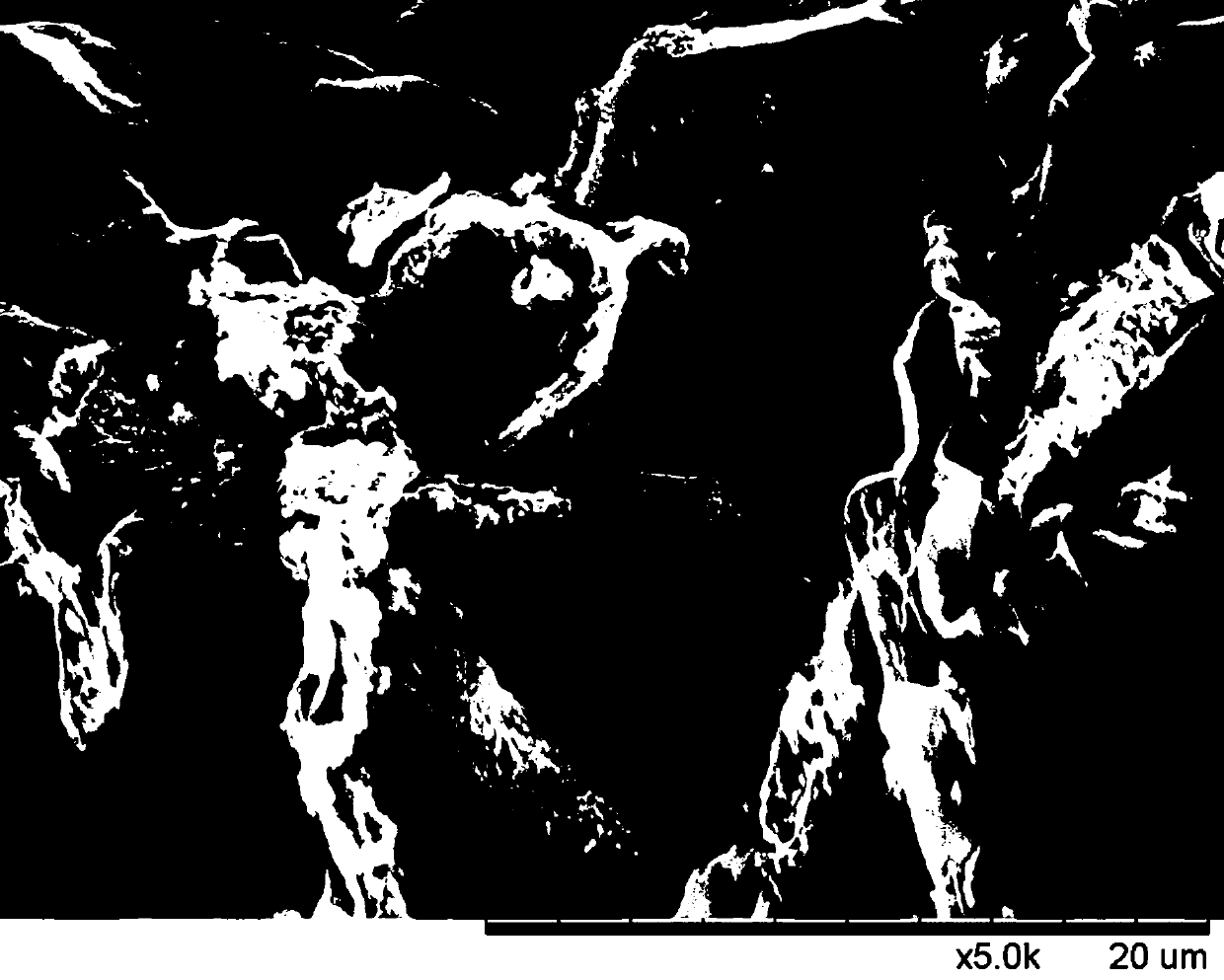

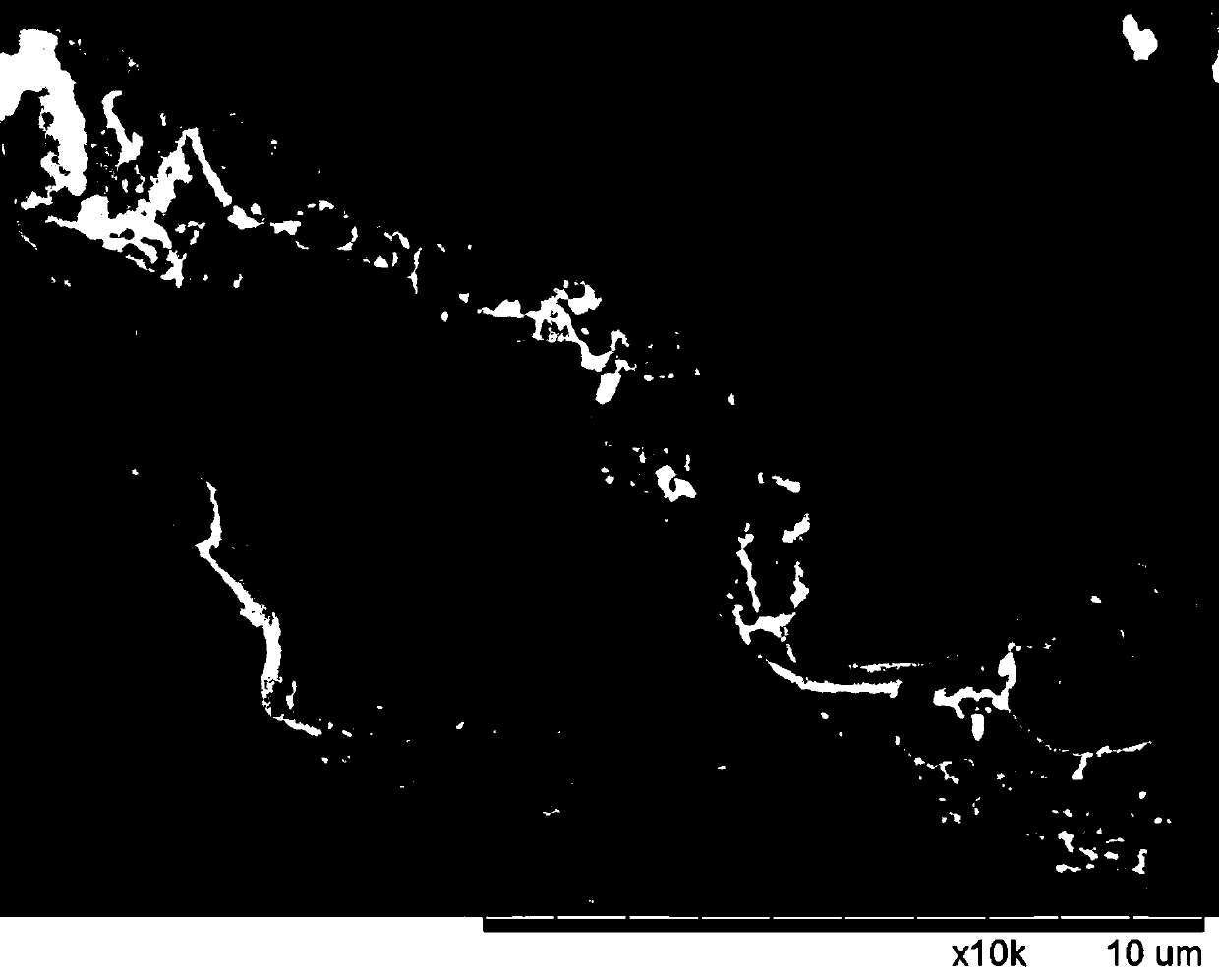

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be described in detail below in conjunction with the embodiments.

[0022] A Penicillium oxalicum that degrades organic acid and odor, which is Penicillium oxalicum DH-1, was deposited in the China Center for Type Culture Collection on April 16, 2018, and the preservation number is CCTCC NO: M 2018201; Address: No. 299, Bayi Road, Wuchang District, Wuhan City, Hubei Province.

[0023] Penicillium oxalicum DH-1 of the present invention is separated and screened from the accumulated dairy cow breeding manure, and the specific steps are as follows:

[0024] (1) Take 0.2 g of dairy cow manure accumulation and inoculate it into 100 mL of liquid screening medium. The configuration steps of the liquid screening medium are as follows: first prepare the basal medium, and the basal medium is based on glucose 20 g / L, tryptone 20 g / L, yeast extract 10g / L, dry cow manure 5 g / L, adjust the pH to 6.5~7.5, add water to the volume, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com