Preparation method of zinc oxide/cuprous oxide heterojunction

A cuprous oxide and zinc oxide technology, applied in the field of chemistry, can solve the problems of high manufacturing cost, poor repeatability, n-type zinc oxide firmly combined with p-type materials, etc., achieving low cost, short reaction period, suitable for large-scale production and applied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

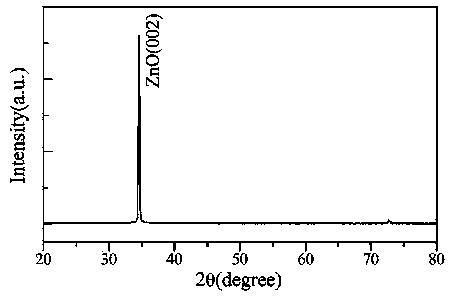

Image

Examples

Embodiment 1

[0043] The preparation method of the zinc oxide / cuprous oxide heterojunction of the present invention comprises the following steps:

[0044] (1) Wash the FTO glass substrate with acetone and ethanol, then ultrasonically clean it with deionized water for 30 minutes, and dry it with nitrogen gas for use;

[0045] (2) Prepare 100mL of zinc chloride solution with a concentration of 0.08mol / L, then add 8mL of ammonia water dropwise to this solution, and stir to obtain a zinc ammine ion solution;

[0046] (3) Put the FTO glass substrate in step (1) into the zinc ammonium ion solution and deionized water in turn for 20 seconds, repeat the above process 3 times, and obtain the substrate with zinc ammonium ion adsorption ;

[0047] (4) At 200°C, heat the substrate with zinc ammonium ions adsorbed thereon for 0.5h, and form zinc oxide nano-crystal seeds on the substrate;

[0048] (5) Put the substrate formed with zinc oxide nano-seeds into the zinc ammonium ion solution, and place th...

Embodiment 2

[0052] The preparation method of the zinc oxide / cuprous oxide heterojunction of the present invention comprises the following steps:

[0053] (1) Wash the FTO glass substrate with acetone and ethanol, then ultrasonically clean it with deionized water for 30 minutes, and dry it with nitrogen gas for use;

[0054] (2) Prepare 100mL of zinc chloride solution with a concentration of 0.02mol / L, then add 3mL of ammonia water dropwise into this solution, and stir to obtain a zinc ammine ion solution;

[0055] (3) Put the FTO glass substrate in step (1) into the zinc ammonium ion solution and deionized water in turn for 30 seconds, repeat the above process 5 times, and obtain the substrate with zinc ammonium ion adsorption ;

[0056] (4) heating the substrate adsorbed with zinc ammonium ions at 350° C. for 1 hour, and forming zinc oxide nano-crystal seeds on the substrate;

[0057] (5) Put the substrate formed with zinc oxide nano-seeds into the zinc ammonium ion solution, and place...

Embodiment 3

[0061] The preparation method of the zinc oxide / cuprous oxide heterojunction of the present invention comprises the following steps:

[0062] (1) Wash the FTO glass substrate with acetone and ethanol, then ultrasonically clean it with deionized water for 30 minutes, and dry it with nitrogen gas for use;

[0063] (2) Prepare 100 mL of zinc chloride solution with a concentration of 0.04 mol / L, then slowly add 5 mL of ammonia water dropwise into this solution, and stir to obtain a zinc ammine ion solution;

[0064] (3) Put the FTO glass substrate in step (1) into the zinc ammonium ion solution and deionized water in turn for 40 seconds, repeat the above process 12 times, and obtain the substrate with zinc ammonium ion adsorption ;

[0065] (4) At 300°C, heat the substrate with zinc ammonium ions adsorbed thereon for 1.5 hours, and form zinc oxide nano-crystal seeds on the substrate;

[0066] (5) Put the substrate formed with zinc oxide nano-seeds into the zinc ammonium ion solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com