A kind of wear-resistant steel with excellent surface quality and preparation method thereof

A surface quality, wear-resistant steel technology, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve problems affecting the appearance of equipment, uneven paint film, affecting surface quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

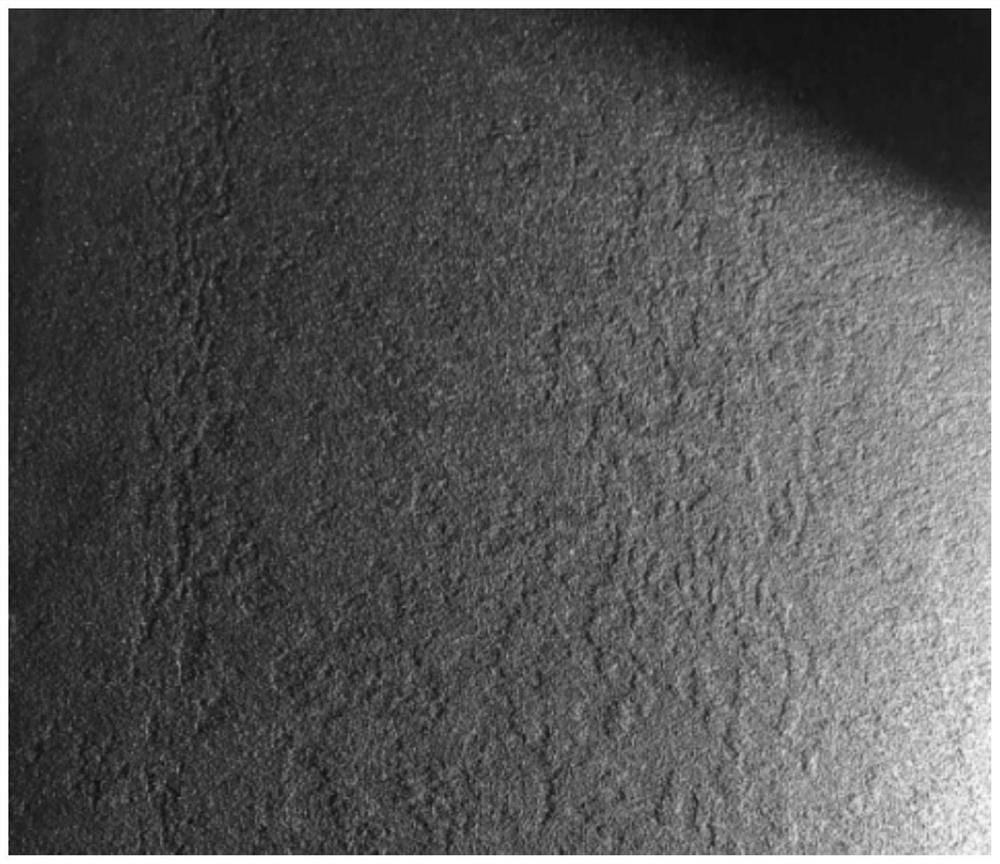

Image

Examples

Embodiment Construction

[0046] Below in conjunction with embodiment the present invention is described in further detail.

[0047] Taking the steel plate as an example, the production process of the wear-resistant steel of the present invention is: converter steelmaking -> LF refining -> VD or RH high vacuum degassing -> continuous casting -> heating -> rolling -> shot blasting -> Quenching -> Tempering.

[0048] The present invention will be further described below in conjunction with Embodiment 1-2. The specific chemical composition of Embodiment 1-2 is shown in Table 1. Steel plate carbon equivalent CEV≤0.4, welding crack sensitivity coefficient PCM≤0.25, which can realize welding without preheating.

[0049] The production method of the low-alloy easy-to-weld wear-resistant steel plate with excellent surface quality in Example 1-2 of the present invention comprises the following steps:

[0050] (1) Smelting: Smelting with a 150-ton converter, the basicity of the final slag of the converter is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com