Preparation method of one-way moisture-conductive antibacterial non-woven fabric

A unidirectional moisture-wicking, non-woven fabric technology, applied in non-woven fabrics, textiles, papermaking, biochemical fiber treatment, etc., can solve the problems of non-woven fabrics with insufficient antibacterial performance and no antibacterial performance, and achieve overall porosity and average pore size Decrease, increase moisture permeability and improve the effect of breeding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1 provides a kind of preparation method of unidirectional moisture-conducting antibacterial non-woven fabric, comprises the steps:

[0058] S1, opening into a net: respectively sending the kapok fiber with an average length of 25mm and the hydrophilic cotton fiber with an average length of 45mm into the opener to open into a net;

[0059] S2, pre-stabbing: the kapok fiber web and the hydrophilic cotton fiber web after opening into a web are pre-punched by acupuncture to obtain a kapok fiber web layer and a cotton fiber web layer;

[0060] Wherein, the pre-punching process of the kapok fiber web layer is: carry out 2 pre-punchings to the kapok fiber web at a frequency of 400 times / min, the pre-punching density is 2000 pieces / m, and the first pre-punching depth is The height of the kapok fiber web layer is stated, and the depth of the second to fourth pre-punching is 4 / 5 of the height of the kapok fiber web layer; the cotton fiber web passes through the upper s...

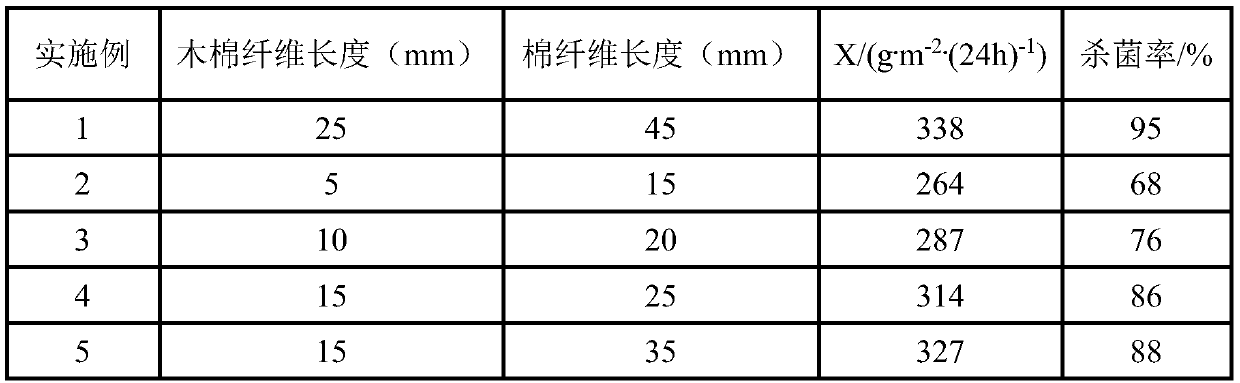

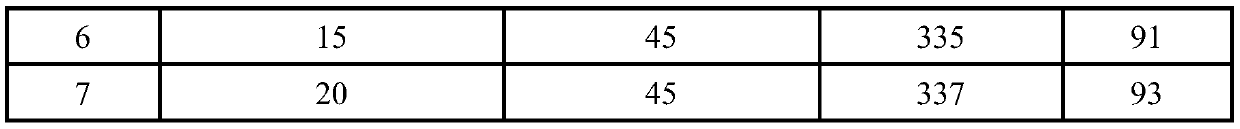

Embodiment 2~7

[0069] Embodiments 2-7 provide a kind of preparation method of unidirectional moisture-guiding antibacterial non-woven fabric, compared with embodiment 1, the difference is that, change the length of kapok fiber and cotton fiber in step S1, except the above-mentioned difference, other operations are all the same. The same, and will not be repeated here; the specific experimental condition parameters and measurement results are shown in the table below.

[0070]

[0071]

[0072] Comparing the results of Examples 1 to 7, it can be seen that the unidirectional moisture-conducting antibacterial non-woven fabrics prepared within the fiber length range defined by the present invention have good moisture permeability and antibacterial properties, and the increase in the length of kapok fiber, cotton fiber As the length increases, the moisture permeability and antibacterial performance of the prepared unidirectional moisture-conducting antibacterial nonwoven fabric show a gradua...

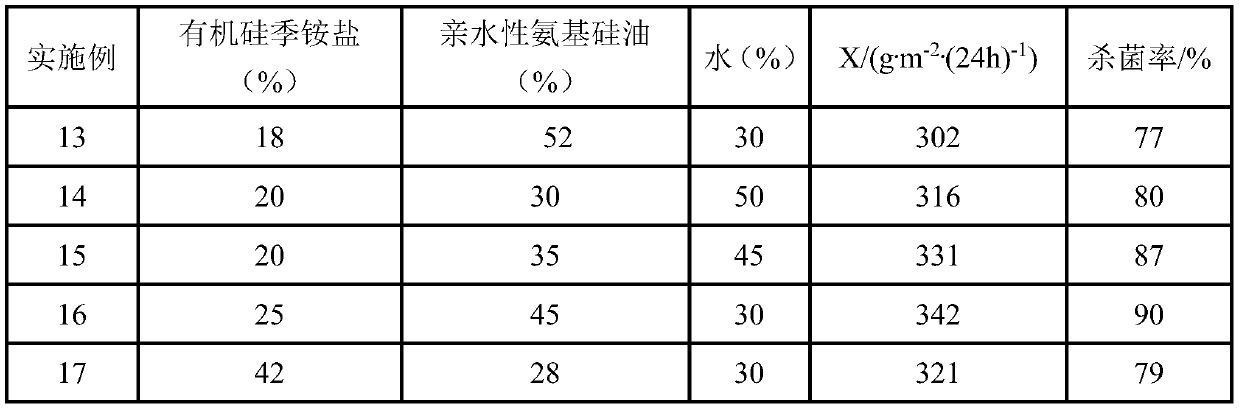

Embodiment 8~12

[0074] Embodiments 8-12 provide a kind of preparation method of unidirectional moisture-guiding antibacterial non-woven fabric, compared with embodiment 1, difference is that, change the weight percent of kapok fiber web layer, cotton fiber web layer described in step S3, Except for the above differences, other operations are the same and will not be repeated here; the specific experimental condition parameters and measurement results are shown in the table below.

[0075] Example Kapok fiber net layer (%) Cotton fiber net layer (%) X / (g.m -2 .(24h) -1 )

[0076] Comparing the results of Example 1 and Examples 8 to 12, it can be seen that as the ratio of the content of the kapok fiber web layer to the cotton fiber web layer increases, the moisture permeability of the prepared unidirectional moisture-conducting antibacterial non-woven fabric decreases gradually, but the bactericidal performance increases first. After subtraction, when the kapok fiber content r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com