Bearing platform foundation backfill structure and construction method thereof

A construction method and basic technology, which is applied in the direction of basic structure engineering, filling, construction, etc., can solve the problems of high construction cost, prominent concrete cracks, and high compaction requirements, so as to improve backfill efficiency, facilitate mechanical lifting, and reduce manpower. The effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

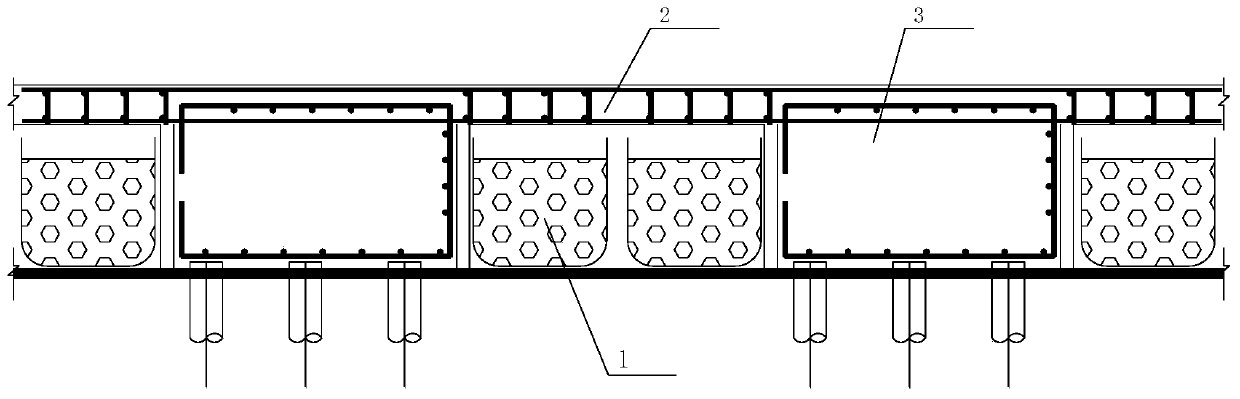

[0036] Combine below figure 1 The structural composition of the cap foundation backfill structure of the present invention is described.

[0037] A cap foundation backfill structure, which includes: a pile foundation structure, a backfill layer and a cap foundation bottom plate 2, the pile foundation structure goes deep into the soil; the backfill layer includes a concrete wrapping layer and a structural member 3 arranged side by side, and the A certain gap is formed, the concrete wrapping layer is located above the pile foundation structure, the concrete wrapping layer is formed by pouring concrete with the backfill material 1, the concrete wrapping layer is located above the pile foundation structure; the cap foundation bottom plate 2 is located above the concrete wrapping layer, the cap foundation bottom plate 2 A fixed connection is formed between the structural members 3 .

[0038] In this embodiment, preferably, the backfill material 1 is several high-density degradable...

Embodiment 2

[0043] Please continue to refer figure 1 , the present invention also provides a construction method for the backfill structure of the cap foundation, the construction method comprising the following steps:

[0044] Step 1. Preparation of backfill material 1: Put the graded gravel into several high-density degradable woven bags with a shovel, and the volume of a woven bag filled with graded gravel is 1 cubic meter;

[0045] Step 2. Backfill material 1 enters the site: lift the woven bag filled with graded gravel with an excavator, and transport it horizontally to the coverage of the lifting equipment;

[0046] Step 3: Backfill material 1 is hoisted in place: After the reinforcement of the cap is bound, use a truck crane or a tower crane to hoist the woven bag filled with graded gravel into the gap between the caps, stack it in a single layer, and avoid the intrusion of the backfill material 1 For the range of structural components, the minimum distance between the backfill ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com