A method for detecting the working state of stamping production line equipment

A technology of production line equipment and working status, which is applied in mechanical equipment, metal processing equipment, fluid pressure actuation system testing, etc., can solve problems such as not very economical and undesirable, unable to predict production line failure trends, and single fault signal, etc., to achieve Reduce spare parts consumption costs and equipment maintenance costs, improve equipment maintenance and management efficiency, and extend the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

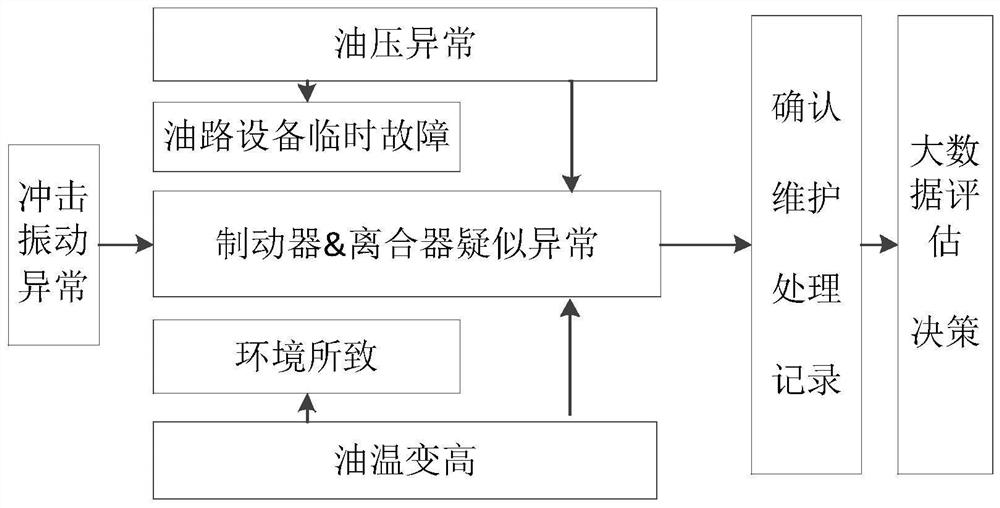

[0028] The core equipment on the stamping production line is the press equipment, and the press equipment is mainly controlled by the brake and clutch inside the press equipment. Therefore, when building the detection method, the parameter detection and evaluation of the brake and clutch are focused. A method for detecting the working state of stamping production line equipment, which includes the following steps: Step 1, regularly collecting oil pressure parameters F (I, T), oil temperature parameters F (X, T) and oil pressure parameters of each unit brake and clutch on the stamping production line Shock vibration parameter F(Y, T), the above parameters all take different values based on time or position, among them, the T variable is unified as the time variable, T=1, 2, 3, ..., t, t+1, the unit is machine Detection cycle, such as collecting data once a week, different values of T represent various parameters of brakes and clutches at different times; I, X, and Y variable...

Embodiment 2

[0037] The basic implementation steps of this embodiment are the same as those in Embodiment 1. The oil pressure trend identification criterion involved can also be the single-point oil pressure time trend identification criterion, and the oil temperature increase identification criterion can be the single-point oil temperature change with time. The high recognition criterion, the vibration trend recognition criterion may be a single-point vibration time trend recognition criterion.

[0038] The difference is that the single-point oil pressure time trend identification criterion can be as follows: obtain the oil pressure abnormal point, and the oil pressure abnormal point is that the oil pressure parameters collected at a single point are higher than the oil pressure parameters at two adjacent time points. The threshold h is lower than the threshold h at the same time as the oil pressure parameters at two adjacent time points, and the occurrence frequency of oil pressure abnorm...

Embodiment 3

[0044] The oil pressure trend recognition criterion involved in this embodiment is also the single point oil pressure time trend recognition criterion, the oil temperature rise recognition criterion is the single point oil temperature rise with time recognition criterion, and the vibration trend recognition criterion is the single point Point vibration time trend identification criterion.

[0045] The second embodiment studies the abnormality of the occurrence frequency of data sudden convex points and sudden concave points, and the present embodiment studies the number of abnormal changes in the overall increase or decrease of data. The single-point oil pressure time trend identification criterion can be as follows: obtain the oil pressure abnormal point, and the oil pressure abnormal point is a sudden change in the average oil pressure parameter collected at a single point. If the number of oil pressure abnormal points reaches n, the criterion is established. During specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com