Phase change heat storage type heat supply system and control method thereof

A heat supply system and phase change heat storage technology, which is applied in heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of inability to ensure the efficiency of charging and discharging heat at the same time, and achieve the purpose of improving the efficiency of charging and discharging heat, and improving the efficiency of heat exchange. Thermal efficiency, the effect of improving system energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Embodiment 1 Preferably,

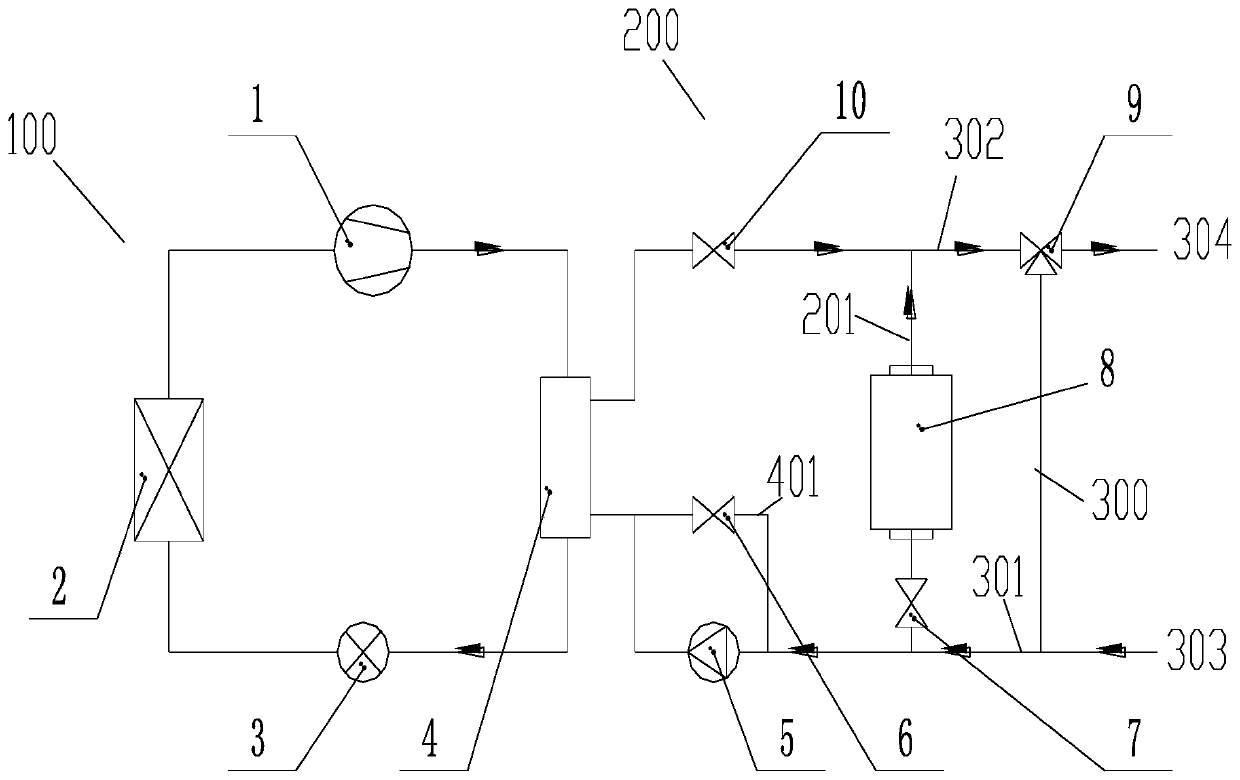

[0066] Such as figure 1 As shown, a first branch 401 is provided in parallel on the circulating water pump 5 , and a first cut-off valve 6 is provided on the first branch. This is the preferred structural form of Embodiment 1 of the present invention, which can effectively realize the parallel connection of the second heat exchanger 4 of the heat pump and the heat accumulator, and realize the second thermal energy in the joint heating mode of the heat pump heating and heat accumulator. The parallel connection of the exchanger and the heat accumulator simultaneously provides the user with water for heating. figure 1 Embodiment 1 of the phase change thermal storage water heater provided by the present invention. The system includes a heat pump heating loop and a water system heat storage and discharge loop. The heat pump heating circuit is composed of compressor 1, first heat exchanger 2, throttling device 3, second heat exchanger 4 and auxil...

Embodiment 2

[0069] Embodiment 2 Preferably,

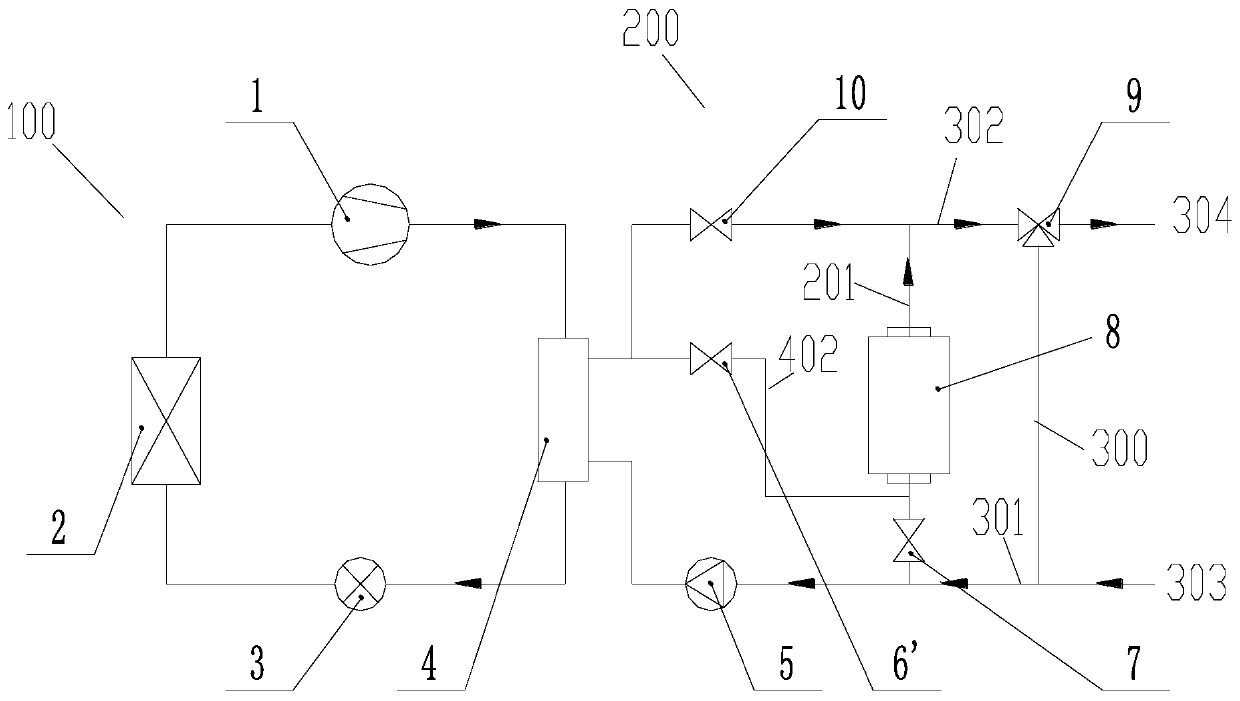

[0070] Such as figure 2 As shown, it also includes a second branch 402, one end of the second branch 402 is connected between the heat accumulator 8 and the second shut-off valve 7, and the other end is connected to the second heat exchanger 4 and the third cut-off valve 10, and a first cut-off valve '6' is also provided on the second branch 402. This is the preferred structural form of Embodiment 2 of the present invention, which can effectively realize the series connection of the second heat exchanger 4 of the heat pump and the heat accumulator, and realize the second thermal The exchanger and the heat accumulator are connected in series, and the second heat exchanger is located at the low-temperature end, and the heat accumulator is located at the high-temperature end, and at the same time, water is supplied to the user for heating.

[0071] figure 2 They are Embodiment 2 of the phase change thermal storage water heater provided by th...

Embodiment 3

[0074] Embodiment 3 Preferably,

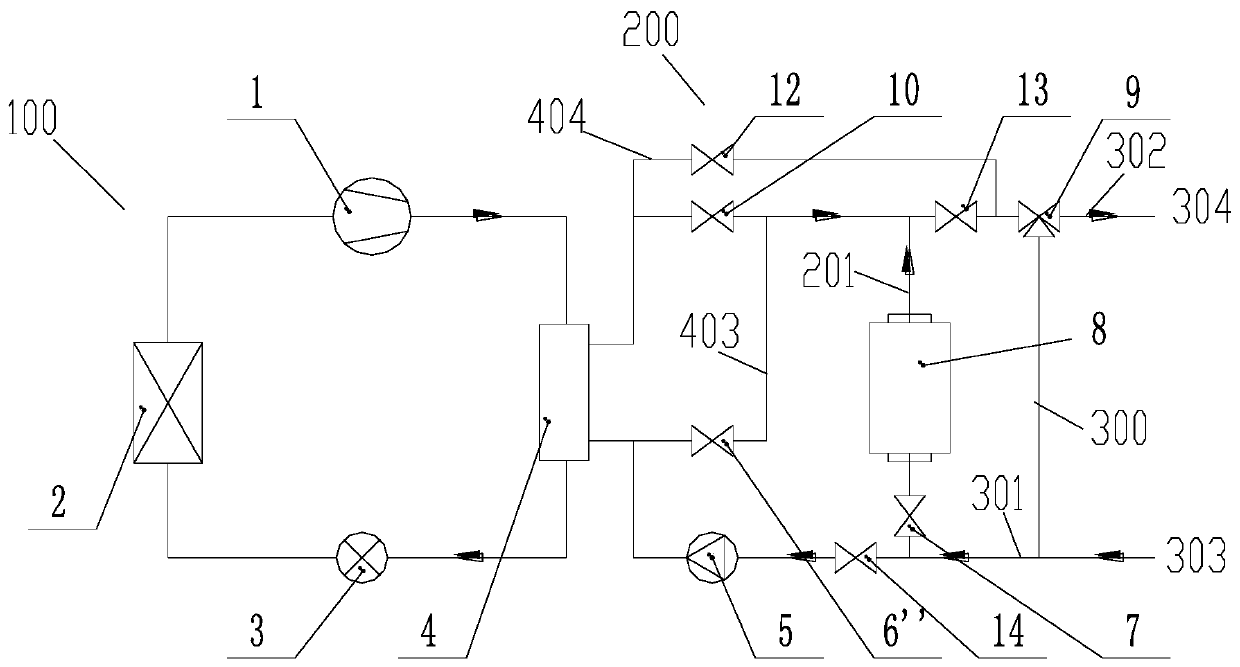

[0075] Such as image 3 As shown, it also includes a third branch 403, one end of the third branch 403 is connected to the position between the second end of the partial pipeline 201 and the third stop valve 10, and the other end is connected to the The position between the third end of the second heat exchanger 4 and the first end of the partial pipeline 201, and the third branch 403 is also provided with a first stop valve "6". This is the preferred structural form of Embodiment 3 of the present invention, which can effectively realize the series connection of the second heat exchanger 4 of the heat pump and the heat accumulator. The series connection of the exchanger and the heat accumulator, and the second heat exchanger is located at the high-temperature end, and the heat accumulator is located at the low-temperature end, and at the same time, water is supplied to the user for heat supply. At this time, the heating energy efficiency is h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com