Multistage compression multi-condenser intermediate complete cooling heat pump drying system

A heat pump drying and condenser technology, applied in the heat pump field, can solve the problems of low system energy efficiency, large compression ratio, large irreversible loss, etc., and achieve the effects of improving economic benefits, reducing exhaust temperature, and reducing irreversible loss of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

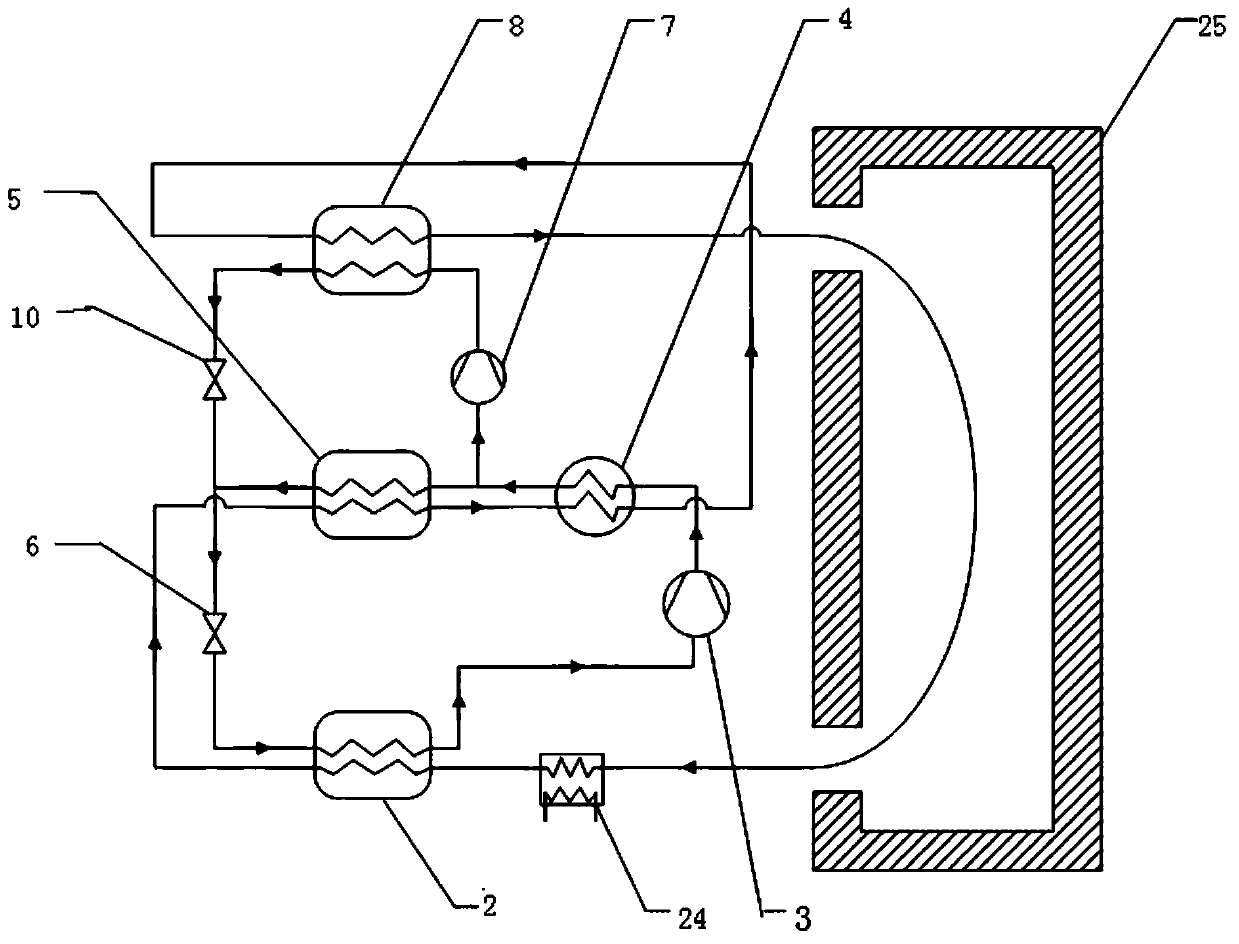

[0024] Example 1: Two-stage compression double condenser intermediate complete cooling heat pump drying system

[0025] This system is composed of the first stage heat pump cycle and the second stage heat pump cycle, and the humid air in the drying room is continuously heated. The system is as follows: figure 1 shown.

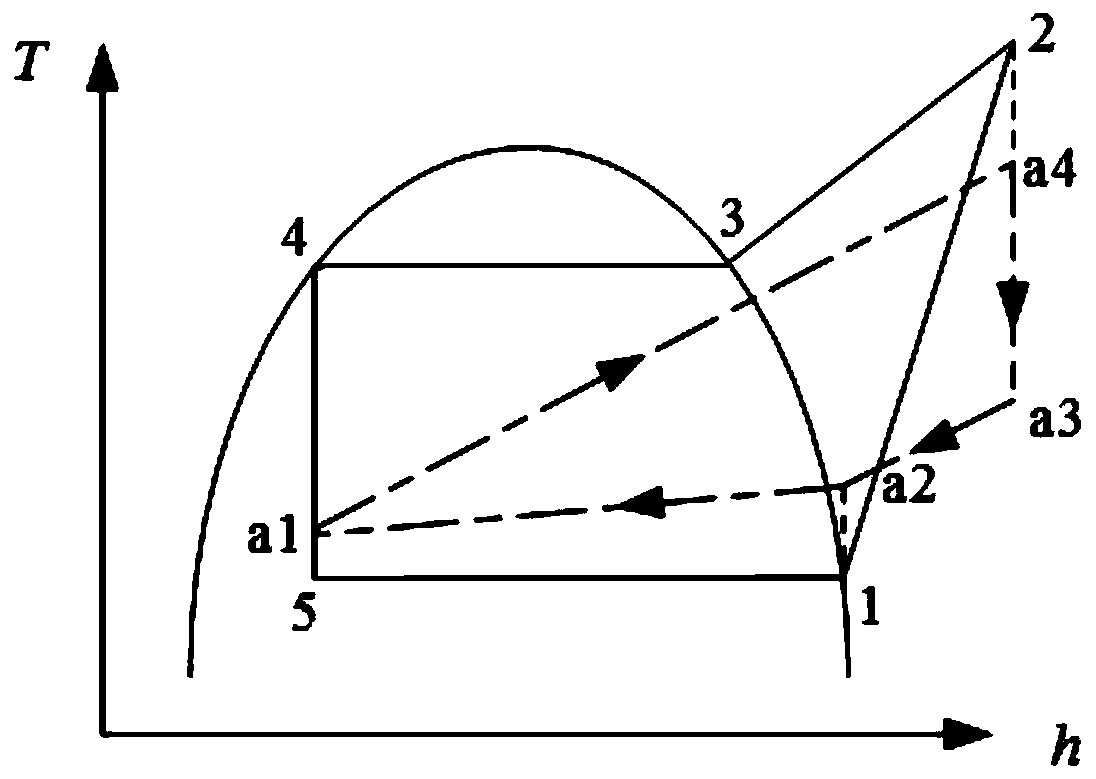

[0026] (1) If the system uses pure working fluid, the temperature and enthalpy diagram of the single-stage pure conventional heat pump drying system is as follows figure 2 shown.

[0027] The specific implementation is as follows:

[0028] The first step: the first-stage compressor 3 sucks the low-temperature and low-pressure working fluid at the outlet of the evaporator 2 working fluid side (such as figure 2 state "1"), compressing it into superheated gas at medium temperature and pressure (such as figure 2 state "2"). Afterwards, the superheated gas flows into the first-stage gas cooler 4 working medium side inlet, and the temperature of the working m...

specific Embodiment approach

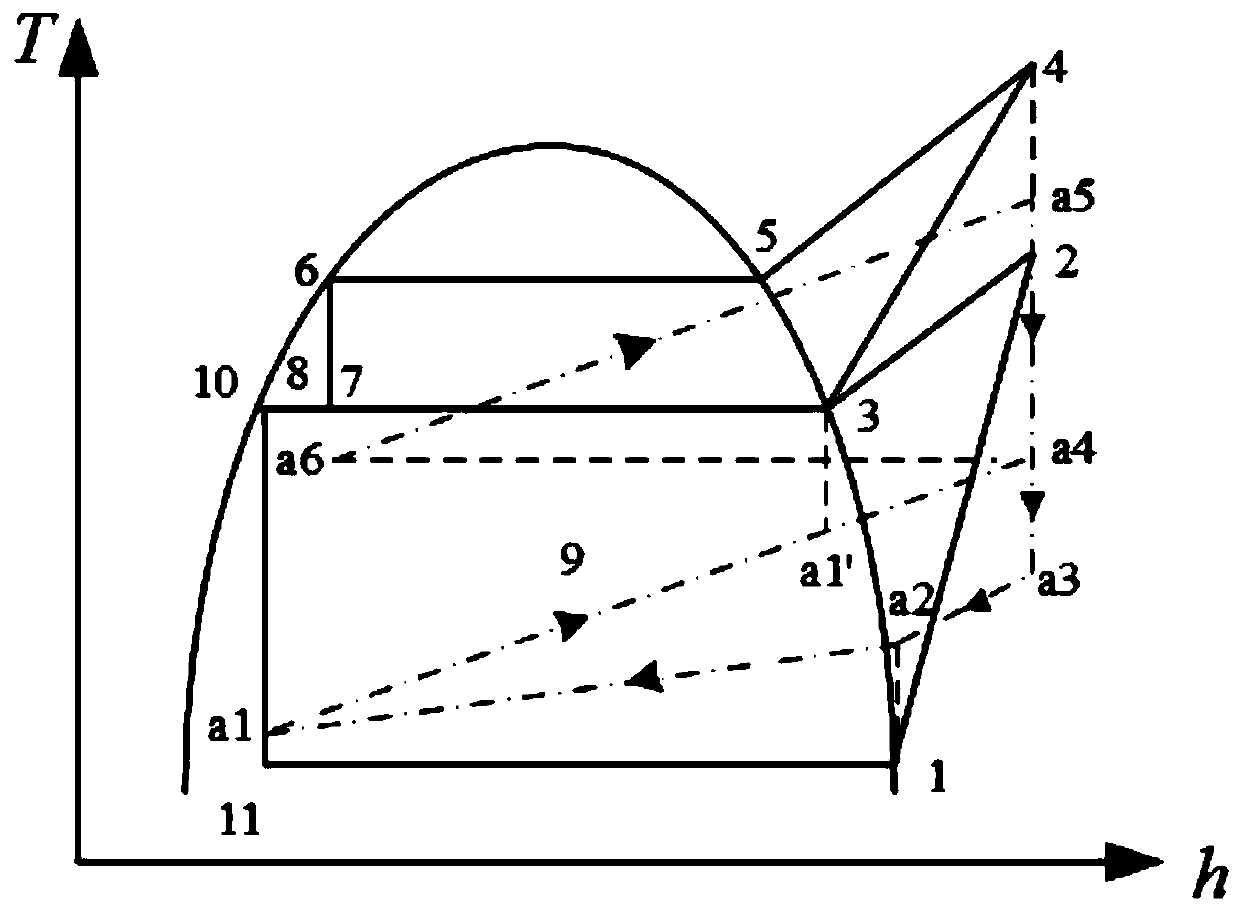

[0030] (2) If the system uses pure working fluid, the temperature and enthalpy diagram of the heat pump drying system with two-stage pure-compression double-condenser complete cooling in the middle is as follows image 3 shown. The specific implementation is as follows:

[0031] The first step: the first-stage compressor 3 sucks the low-temperature and low-pressure working fluid at the outlet of the evaporator 2 working fluid side (such as image 3 state "1"), compressing it into superheated gas at medium temperature and pressure (such as image 3 state "2"), then the superheated gas flows into the first-stage gas cooler 4 working medium side inlet, and the temperature of the working medium in the gas cooler 4 decreases after heat exchange (such as image 3 state "3"), then the gas is divided into two paths, and all the way flows into the first-stage condenser 5 to be condensed to saturated liquid (such as image 3 state "8"), and then the working fluid enters the first-stage...

Embodiment 2

[0041] Embodiment 2: A heat pump drying system with multiple condensers in the middle of three stages of compression and above is completely cooled.

[0042] This device can also be designed as a complete heat pump drying system in the middle of a multi-stage compression multi-stage condenser according to specific implementation needs, so as to realize multiple times of air drying, so as to better adapt to the drying process requirements of different materials. Specific examples of multi-stage compression multi-stage condenser intermediate complete heat pump drying system are as follows: Figure 5 .

[0043] The specific implementation is as follows:

[0044] Step 1: The first-stage compressor 3 sucks the low-temperature and low-pressure working fluid at the outlet of the working medium side of the evaporator 2, compresses it into superheated gas at intermediate pressure, and then enters the first-stage gas cooler 4 for heat exchange. After that, it is divided into two roads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com