Symmetrical multi-line transient tropical solid high-heat-conductivity-coefficient testing device

A technology with high thermal conductivity and high thermal conductivity, applied in the direction of thermal development of materials, can solve the problems of poor test repeatability, multi-user, low signal-to-noise ratio, etc., and achieve the effect of reducing production cost and improving thermal diffusivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

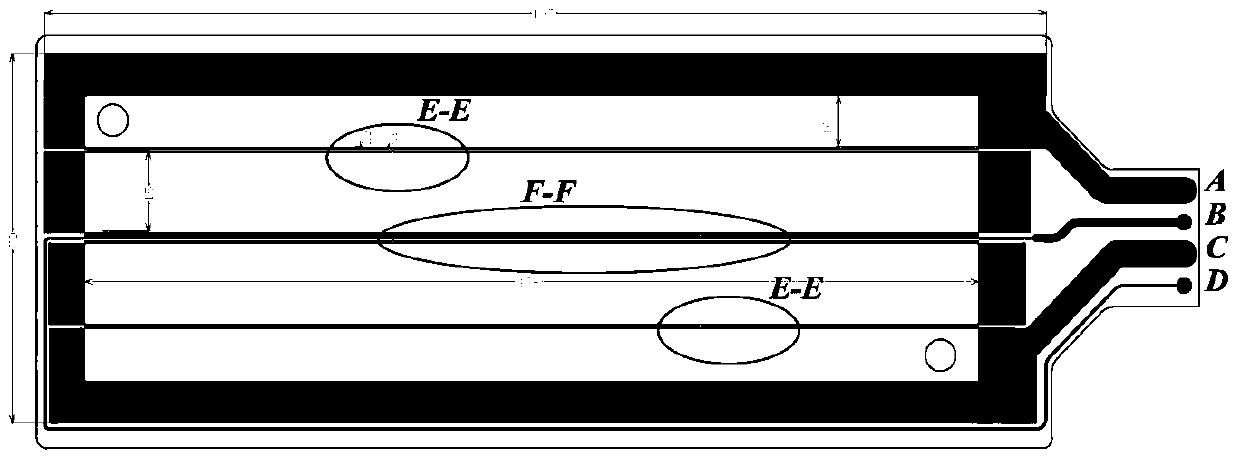

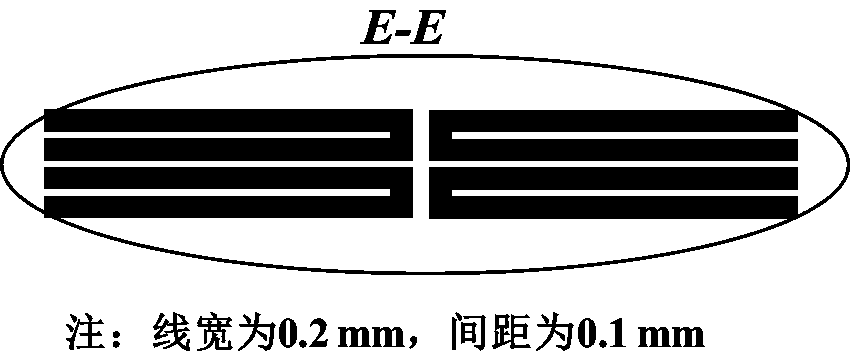

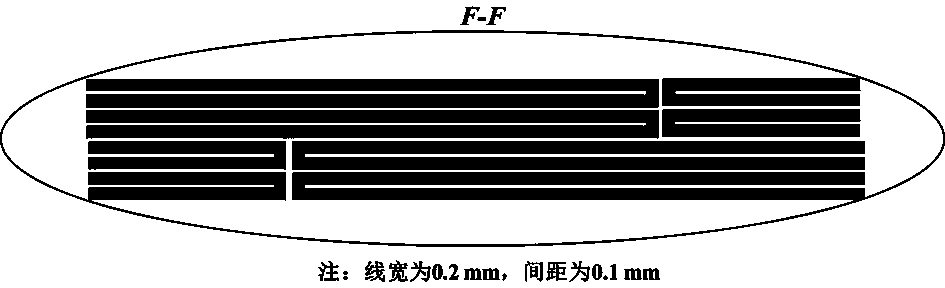

[0039] refer to figure 1 The structural diagram of the heating chip of the present invention shown, figure 2 and image 3 gives figure 1 The schematic diagram of the enlarged structure of the local area E-E and the local area F-F and the size of the heating wire are marked in the figure, and the unit in the figure is mm.

[0040] A power supply is used to provide constant energy for the two opposite nodes of the heating plate; wherein, the power supply can be a constant current source, a constant voltage source, or a constant power source;

[0041] The data acquisition system is used to collect the voltage and temperature changes of the other two relative nodes after the same material to be tested is attached to the upper and lower surfaces of the heating plate, and obtain the thermal conductivity of the material to be tested.

[0042] In a specific implementation process, the pitch of each metal line constituting the hot zone is 0.1 mm, and the minimum width of the metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com