Composite heating type heat storage soldering iron

A composite heating and heat storage technology, used in soldering irons, electric heating devices, metal processing equipment, etc., can solve problems such as burning out electronic components, and achieve the effect of improving heating efficiency, flexible heating methods, and improving welding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

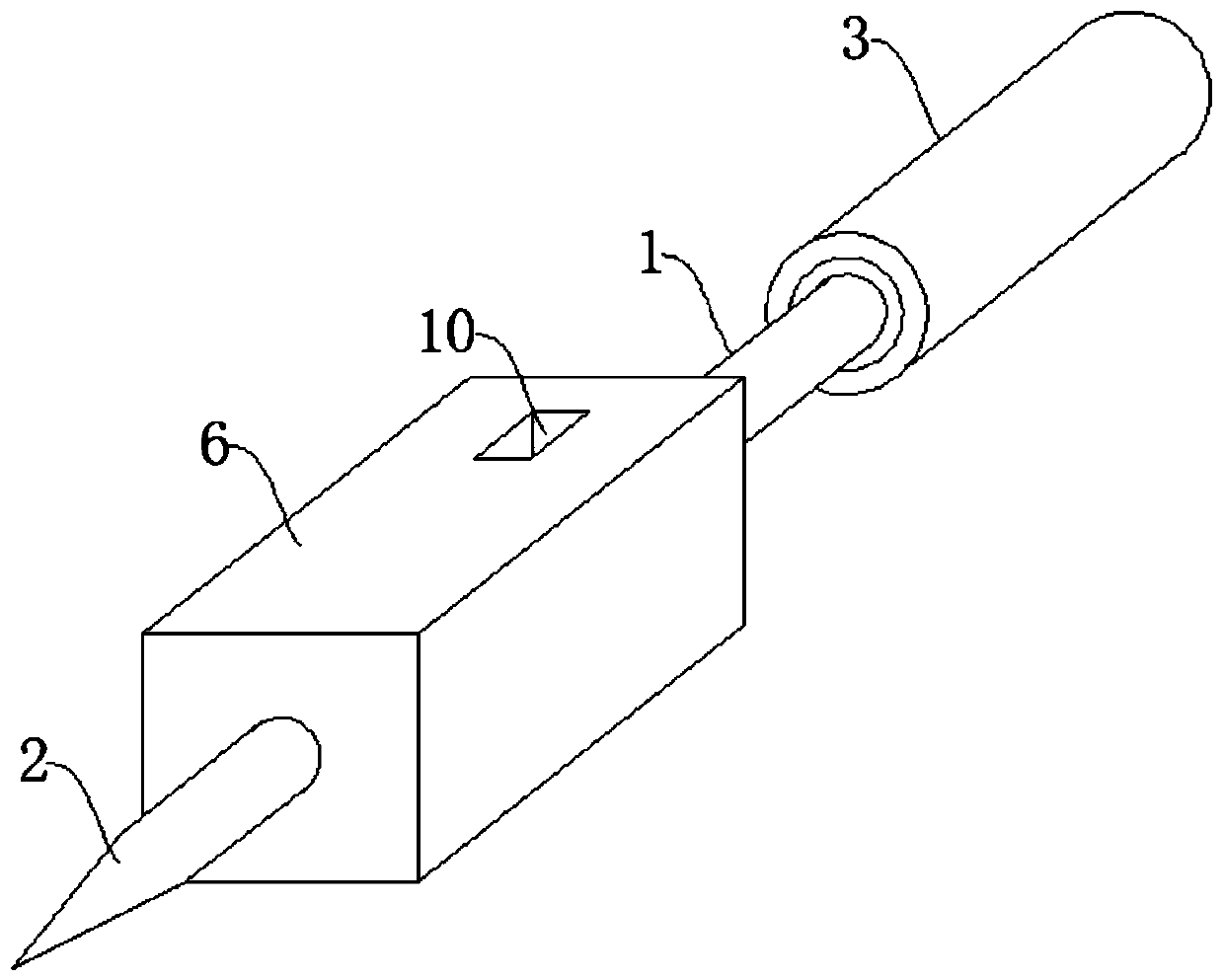

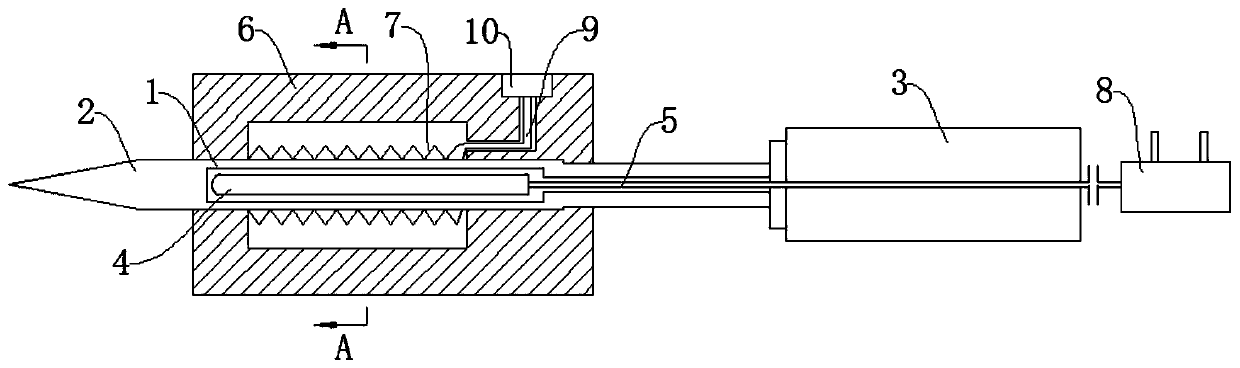

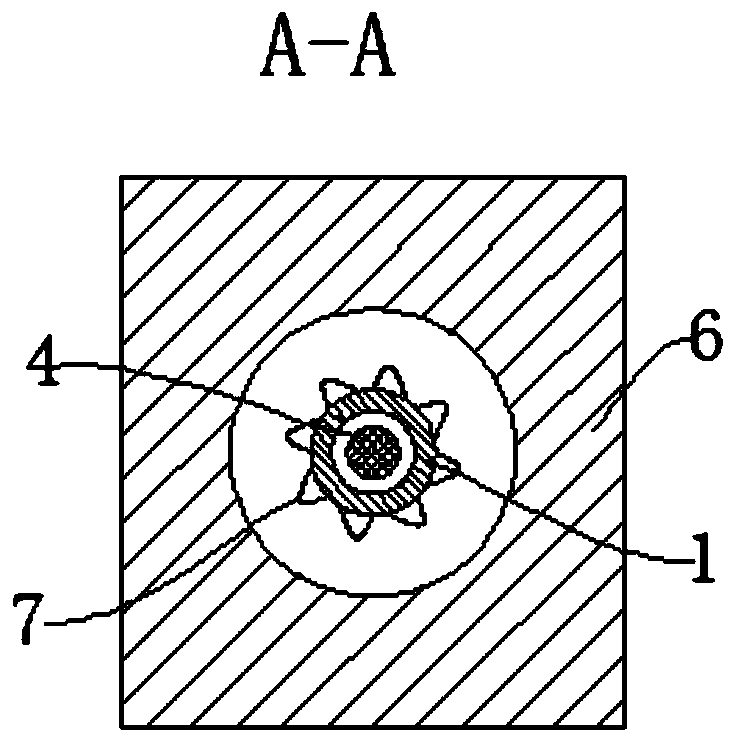

[0034] Embodiment one: if Figure 1 to Figure 3 As shown, the present invention provides a composite heating heat storage type soldering iron, which includes a hollow soldering iron core 1, a soldering iron tip 2 is provided at one end of the soldering iron core 1, a handle 3 is connected to the other end of the soldering iron core 1, and the hollow soldering iron core 1 The soldering iron core 1 is provided with an inner heating wire 4, and the inner heating wire 4 is connected with an inner heating wire 5 near the end of the handle 3, and a hollow heat storage metal block 6 is arranged on the outer coat of the soldering iron core 1, and the soldering iron core 1 An external heating wire 7 is wound around the outside, and the external heating wire 7 is located in the cavity of the heat storage metal block 6 . The soldering iron of the present invention has two electric heating methods, the inner heating wire 4 and the outer heating wire 7, the heating methods are flexible and...

Embodiment 2

[0039] Embodiment two: if Figure 4-6As shown, on the basis of the first embodiment, the heat storage metal block 6 is provided with a flame heating surface 11 . The heat storage metal block 6 is covered with an insulating layer 12 except the flame heating surface 11 . When there is no other power supply such as mains electricity and vehicle, an open flame heat source such as an alcohol lamp can be used to heat the heating surface of the heat storage metal block 6, and the temperature of the soldering iron can be determined by the temperature of the bimetal sheet on the heat storage metal block 6, and then the electronic unit Soldering of devices. The insulation layer 12 is insulation materials such as aluminum silicate insulation cotton, and the insulation shell is sheathed outside the insulation material, such as a rubber layer. Simple soldering of electronic components can also be realized without power supply, which further improves the application range of the soldering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com