Holographic copying painting base and production method thereof

A production method and substrate technology, applied in chemical instruments and methods, wood layered products, special decorative structures, etc., can solve the problems of lack of texture and touch, reduced durability, and inability to display outdoors, etc., to achieve the installation method Simple, quick and durable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

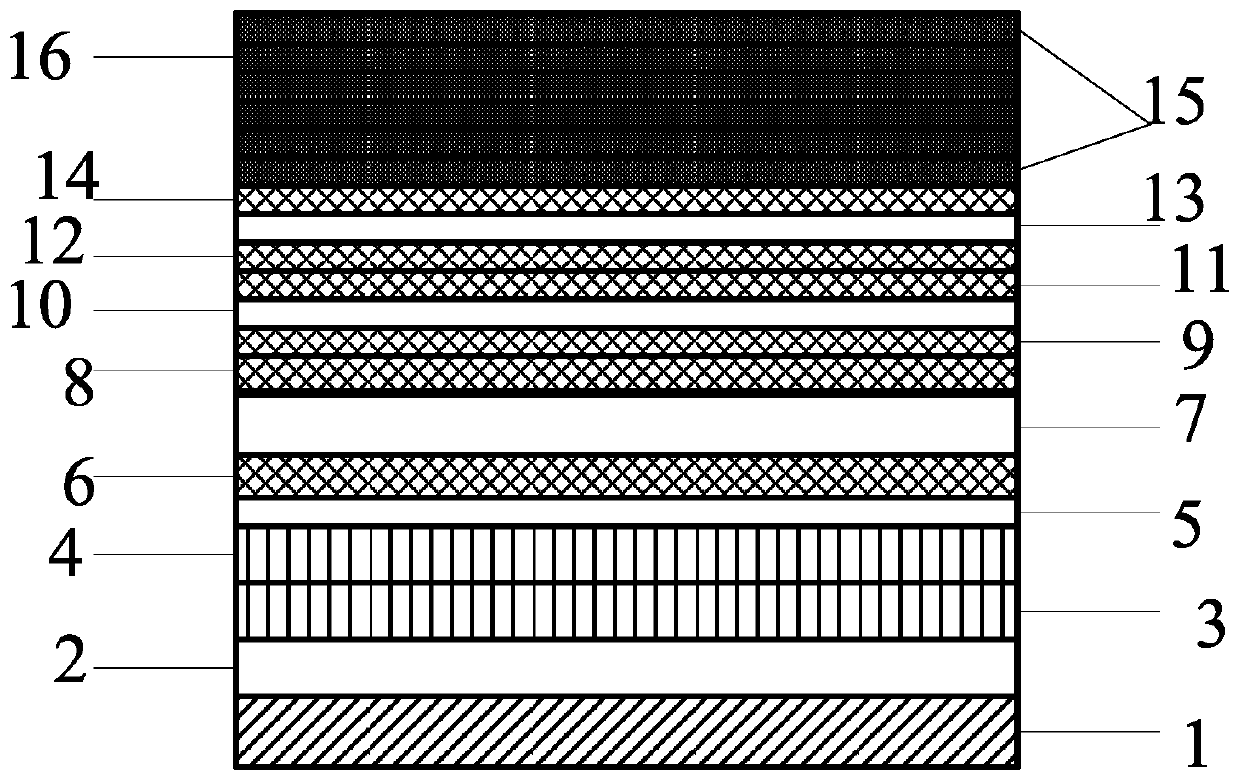

[0116] This embodiment provides a method for manufacturing a holographic copy painting base, wherein the method includes the following specific steps:

[0117] (1) Set the base substrate layer on the lining board of the marble board 1 (pure linen cloth), and then scrape the first layer of primer on the base substrate layer 2 to form the first primer layer 3, and wait for the second Scrape the second layer of primer after one layer of primer is completely dry to form the second primer layer 4, and form the primer layer after the second layer of primer is completely dry;

[0118] In step (1), the primer can be "Sankeshu White Latex", "Brothers Haobai Latex" and so on;

[0119] (2) Continue to scrape the primer on the primer layer to form the rock-sand soil primer layer 5; immediately spray the first diluted aqueous solution of the blending glue on the rock-sand soil primer layer to form the first dilution blending glue layer 6, Lay the first rock-sand soil layer 7 on the first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com