Method of growing graphene film on insulating substrate in absence of catalyst

A technology of graphene film and insulating substrate, which is applied in the field of growing graphene film on non-catalyst insulating substrate, which can solve the problems of complex graphene principle, easy pollution, and large external interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

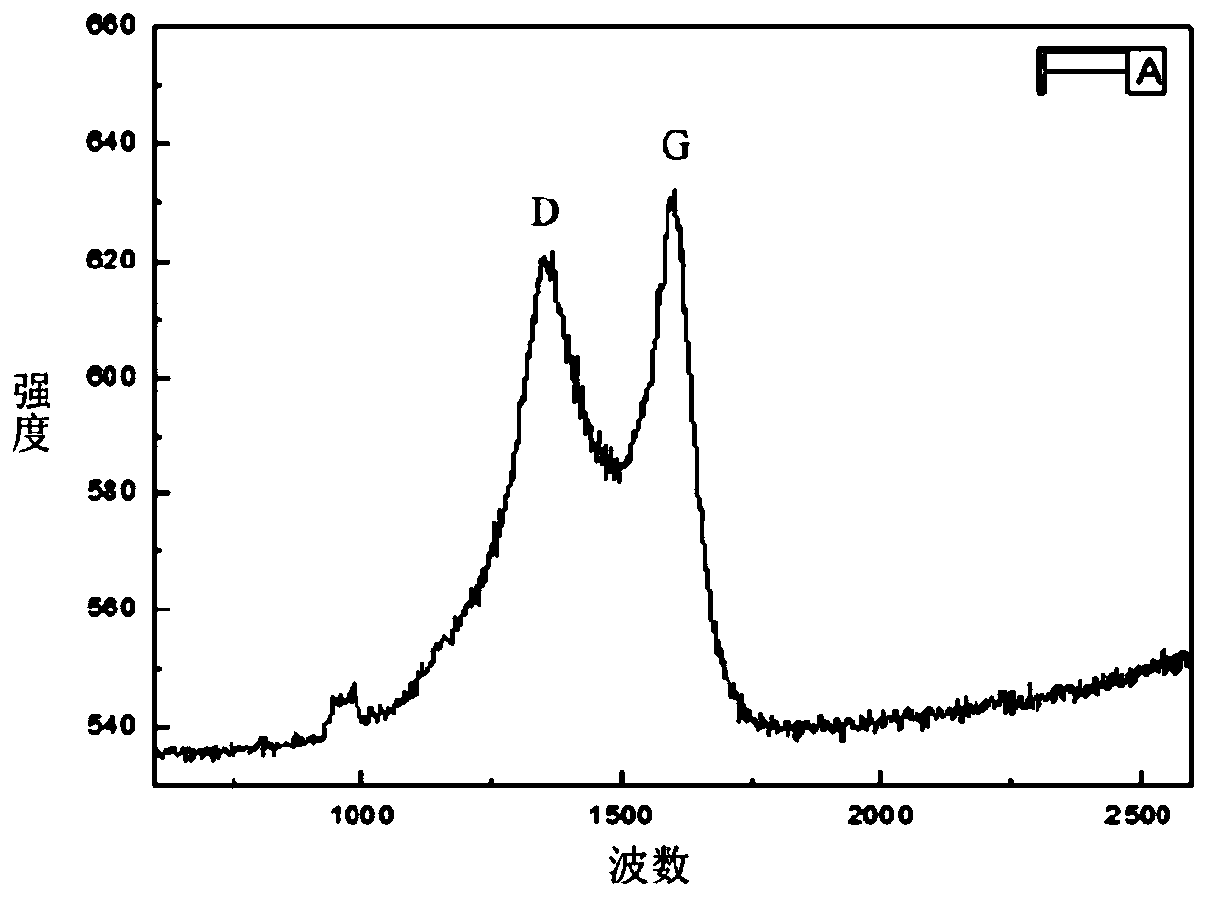

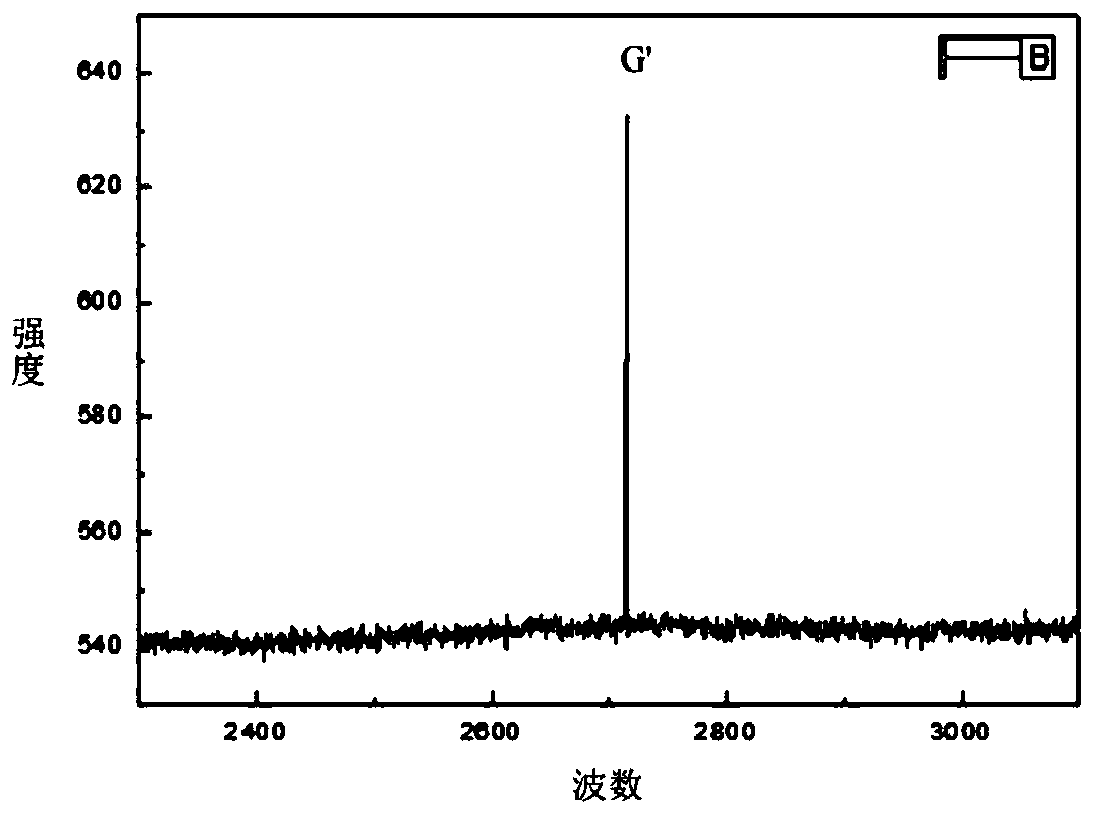

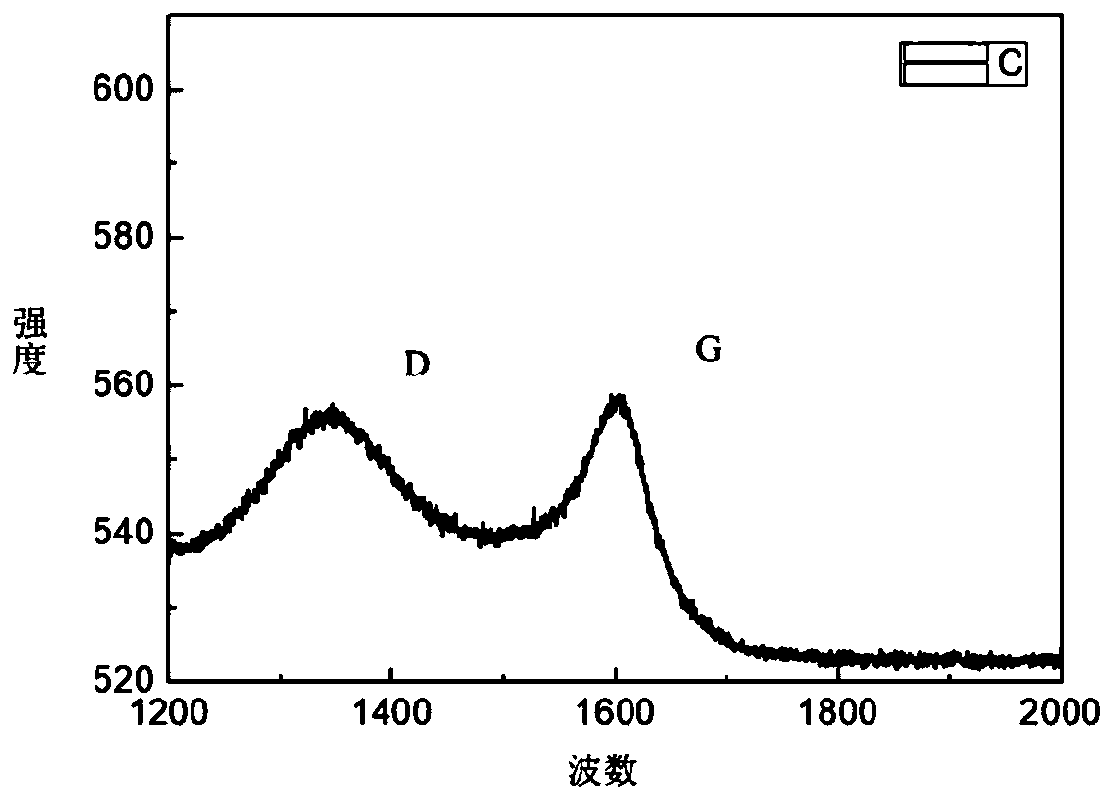

Image

Examples

Embodiment 1~4

[0024] A method for growing a graphene film on a catalyst-free insulating substrate, comprising the following steps:

[0025] 1) Prepare a quartz tube, the length and inner diameter of the quartz tube are shown in Table 1. The two ends of the quartz tube are the raw material end and the base end respectively, and an insulating base (with an area of 1 cm × 2 cm) is placed in the base end of the quartz tube. The insulating base is shown in Table 1. Put a raw material of quality X in the raw material end of the quartz tube, the raw material is polyethylene, vacuumize the quartz tube, seal the quartz tube after vacuuming, so that the pressure inside the quartz tube is P.

[0026] 2) Heat the raw material end and the base end of the quartz tube for 60 minutes at the same time, and then cool to room temperature 20-25°C with the furnace after heating, and obtain a graphene film on the insulating substrate, wherein the temperature gradient between the raw material end and the base e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com