Hydraulic control system for spray head of concrete wet spraying machine

A technology of hydraulic control system and wet spraying machine, which is applied in the direction of mechanical equipment, earthwork drilling, fluid pressure actuation device, etc. It can solve the problems of inaccurate position of the maximum angle, low rebound degree, and reduced construction accuracy, etc., to achieve the realization of way simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

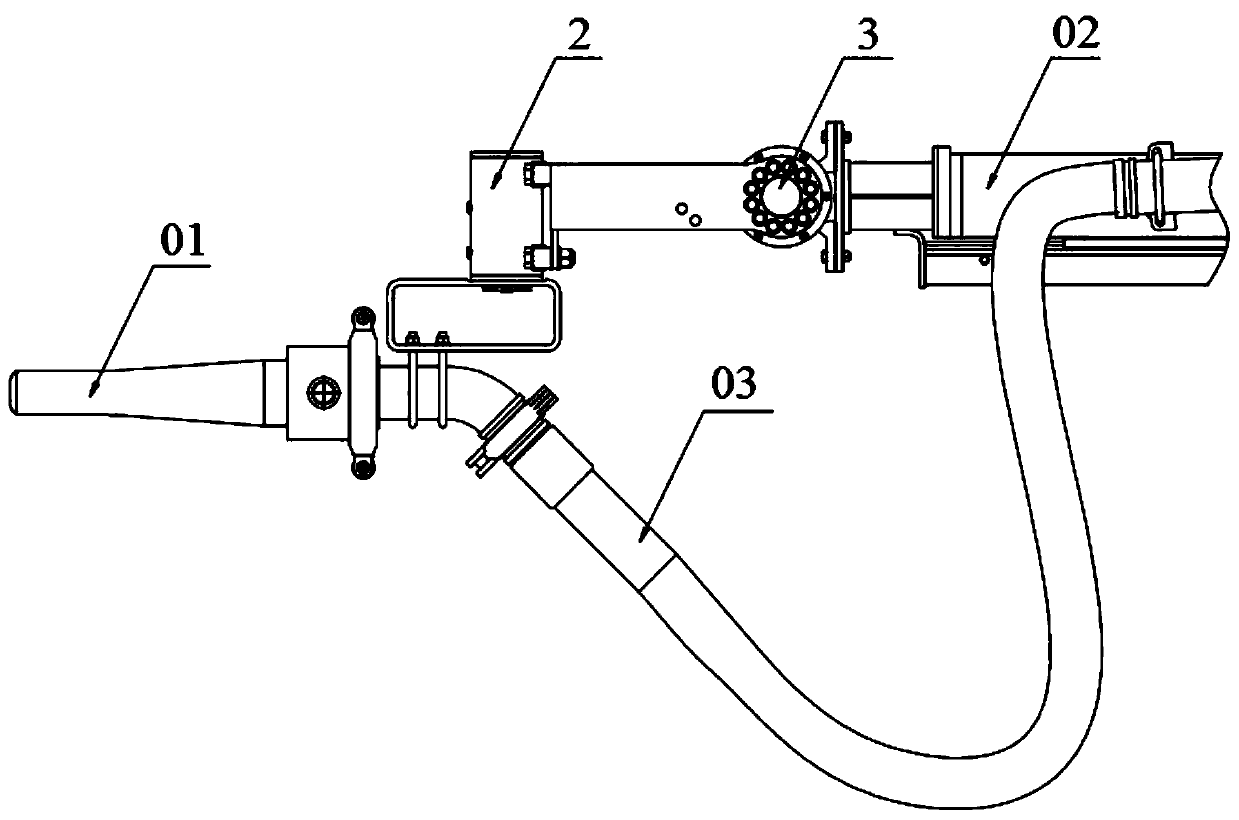

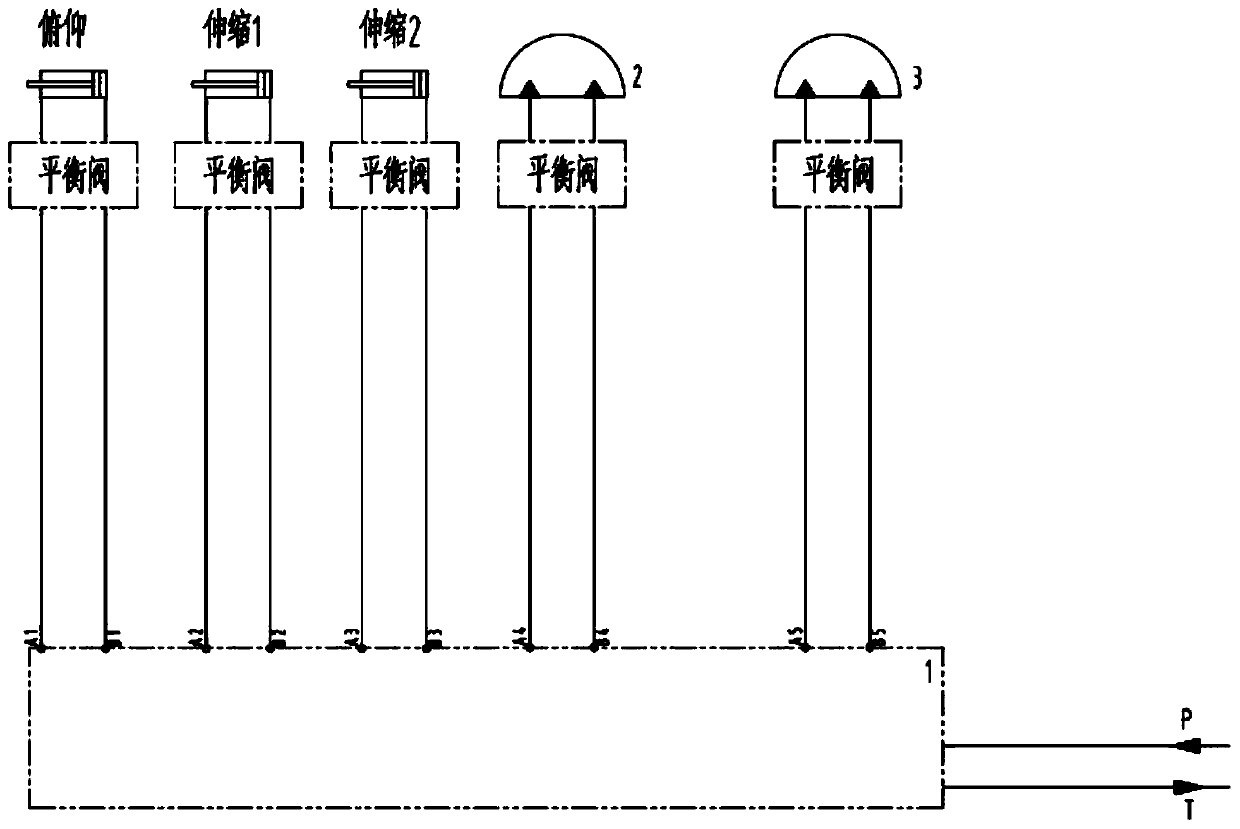

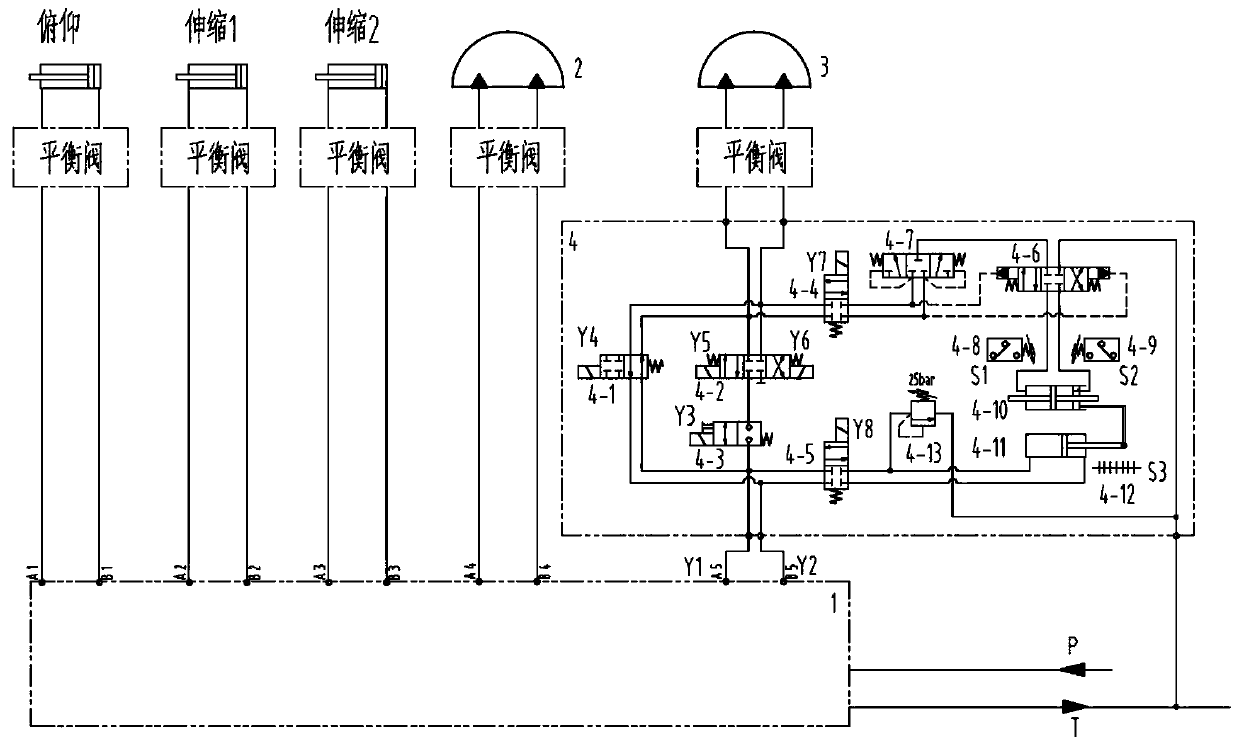

[0038] See figure 2 , The existing hydraulic control system for the nozzle of the concrete wet spraying machine includes the oil pipeline, the multi-way valve 1, the horizontal swing cylinder 2, the vertical swing cylinder 3, one boom pitch control cylinder and two boom telescopic control cylinders; The way valve 1 is connected to an oil tank through an oil pipeline. The horizontal swing cylinder 2, the vertical swing cylinder 3, the boom tilt control cylinder, and the boom telescopic control cylinder are all connected to the multi-way valve 1.

[0039] The horizontal swing cylinder 2 is used to realize the swing of the spray head in the horizontal range, and the vertical swing cylinder 3 is used to realize the swing of the spray head in the vertical range. The multi-way valve 1 supplies pressure oil to the above-mentioned cylinder. It controls all the movements of the boom, including the horizontal swing cylinder 2 and the vertical swing cylinder 3, and can realize all actions b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com