A coal gangue brick drying equipment

A drying equipment and technology for coal gangue, applied in the field of coal gangue brick drying, can solve the problems of high energy consumption, high economic cost, insufficient utilization of hot air, etc., and achieve the effect of improving uniformity and ensuring drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

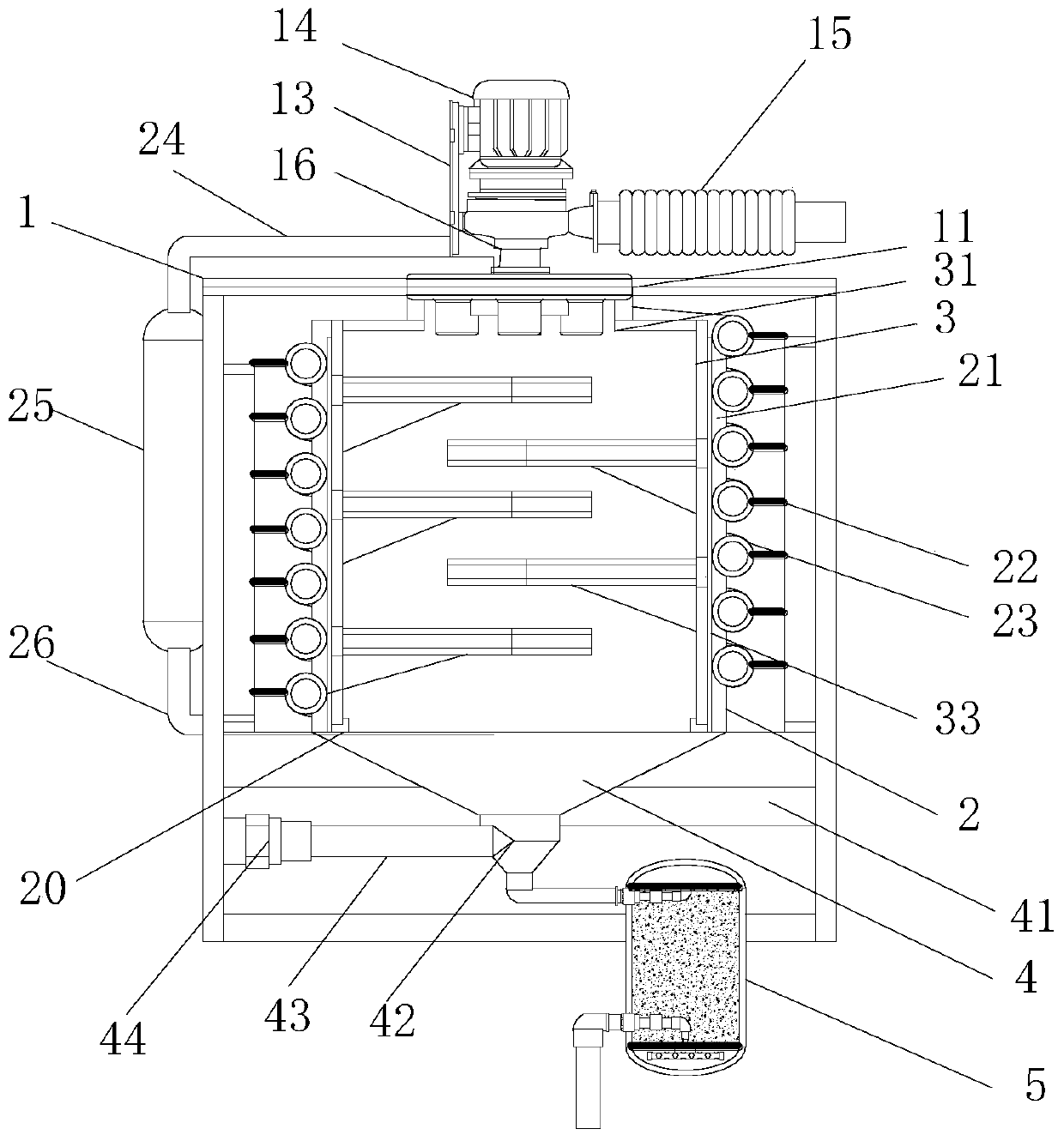

[0034] see figure 1 , a coal gangue brick drying equipment, comprising an outer frame 1, a drying chamber 2 is built in the outer frame 1, and a loading box 3 is installed in the drying chamber 2, and the drying chamber 2 An annular slot 20 is provided at the bottom, and the bottom of the carrying case 3 is embedded in the annular slot 20 . The loading box 3 is erected in the drying chamber 2 in a suspended manner.

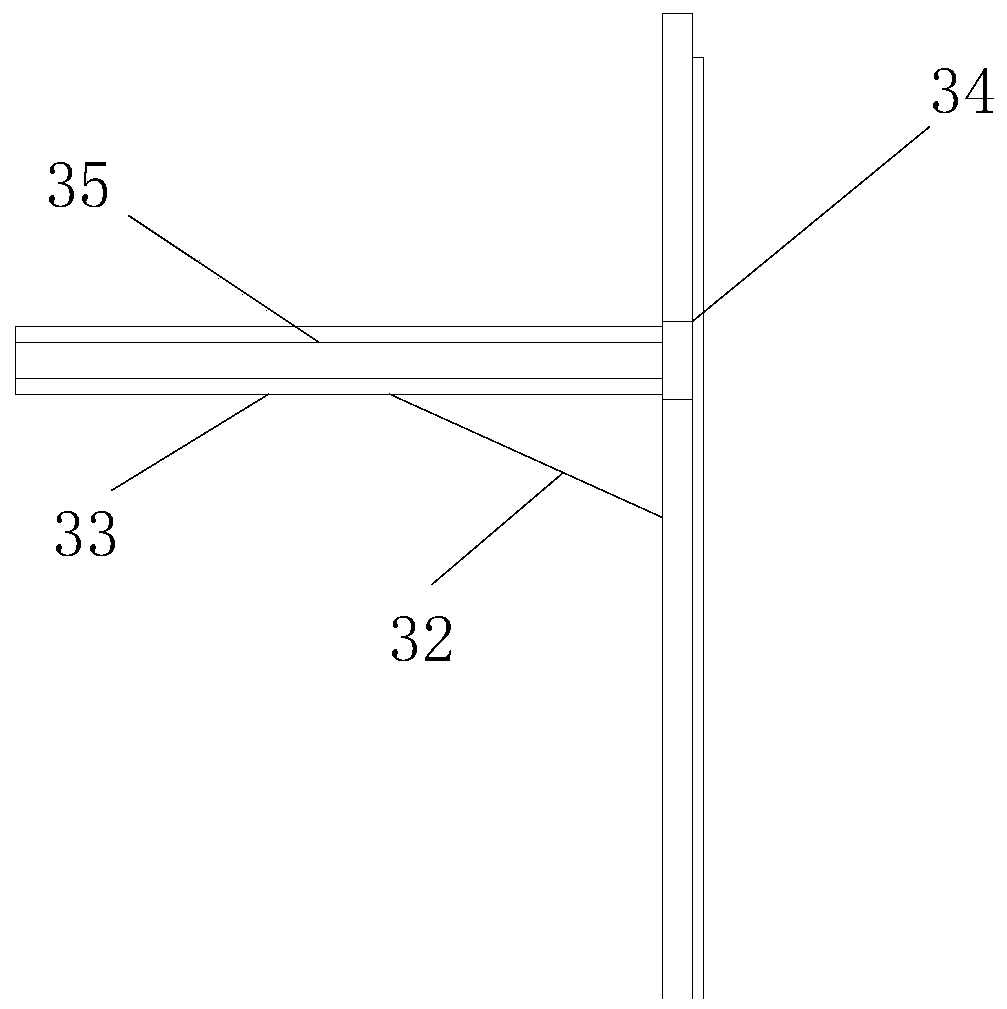

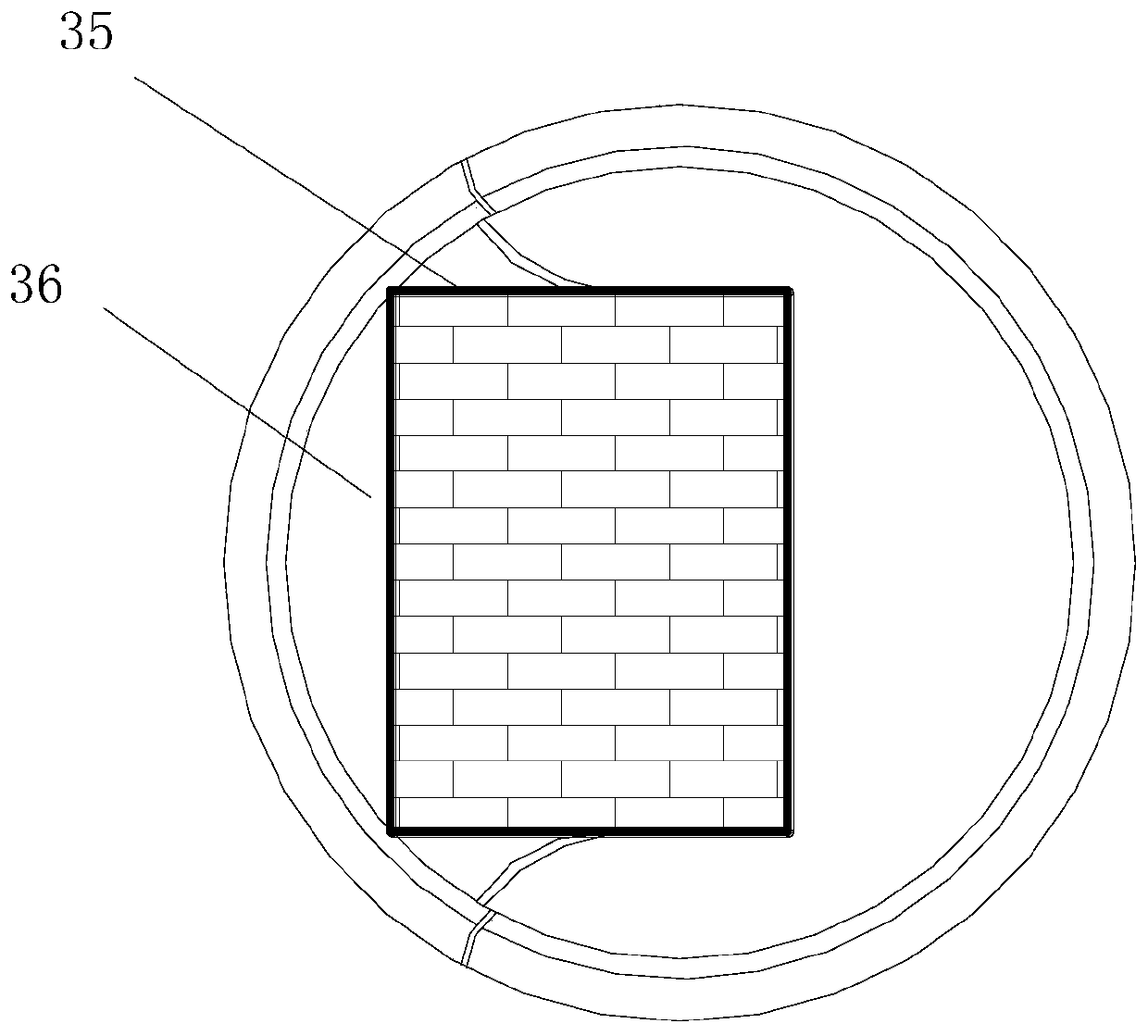

[0035] see figure 1 and Figure 4 , the top of the loading box 3 is provided with an air inlet 31, and the top of the outer frame 1 is provided with an air inlet cover 11, and the air inlet cover 11 is covered at the air inlet 31, and the The top of the air intake cover plate 11 is provided with a top frame 13, an air pump 14 is installed on the top frame 13, the air intake end of the air pump 14 is externally connected to the air intake pipe 15, and the gas end of the air pump 14 is equipped with The air delivery pipe 16, the bottom of the air intake cover 11...

Embodiment 2

[0044] see figure 1 , Figure 7 and Figure 8 , this embodiment is a further optimization of Embodiment 1. On the basis of it, the bottom of the drying chamber 2 is provided with a moisture discharge chamber 4, and the moisture discharge chamber 4 is arranged as a bucket-shaped structure, and the moisture The bottom of the discharge chamber 4 is equipped with an exhaust end 42, and the side of the exhaust end 42 is connected with a booster pipe 43, and a guide fan 44 is installed on the booster tube 43, and the exhaust end 42 The bottom is connected to the exhaust pipe 54. The moisture discharge chamber 4 is installed on the bottom of the outer frame 1 through a bottom bracket 41 .

[0045] The bottom of the outer frame 1 is equipped with a drying box 5, and the drying box 5 is provided with an air inlet chamber 52, a drying chamber 51 and an exhaust chamber 53, and the air inlet chamber 52, the drying chamber 51 and the exhaust chamber 53 are arranged from top to bottom, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com