Method for measuring micro vibration in the optical axis of remote sensing satellite camera

A remote sensing satellite and measurement method technology, applied in the field of spacecraft measurement and control, can solve the problems of remote sensing satellite camera optical axis micro-vibration monitoring, short duration of micro-vibration measurement, limited reliability, etc., so as to improve design accuracy and improve system performance. Reliability and the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

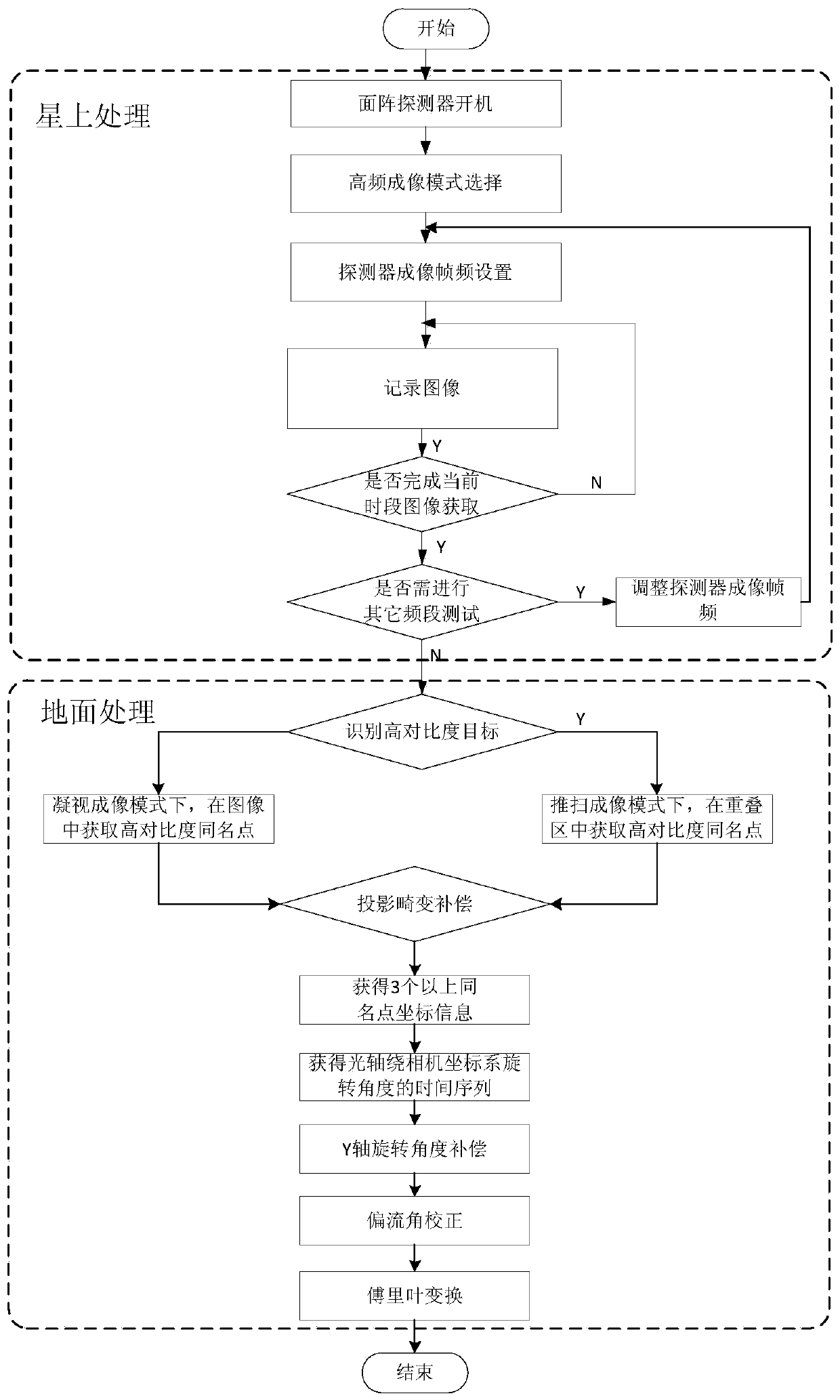

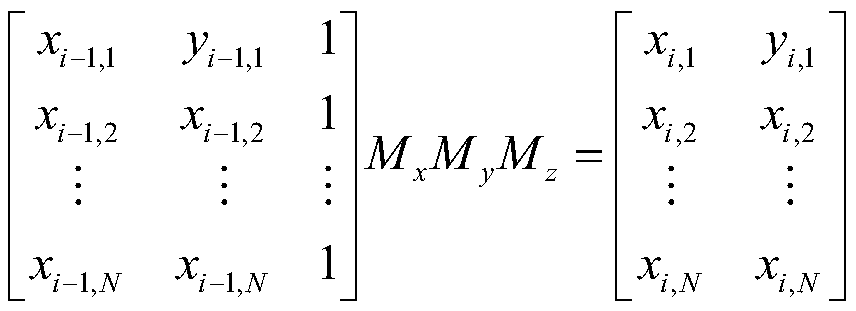

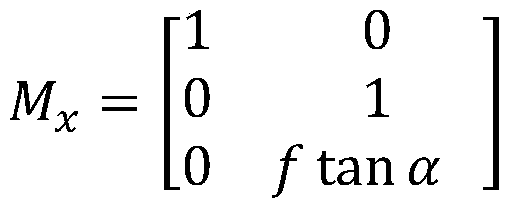

[0046] Such as figure 1 As shown, a remote sensing satellite camera optical axis micro-vibration measurement method involves a remote sensing satellite camera optical axis information sensitive method, which solves the optical axis deviation introduced by remote sensing satellite cameras due to factors such as satellite platform interference, installation errors, and environmental conditions. The problem of measurement of displacement, and the problem of image quality attenuation brought along with it. The method includes the following steps:

[0047] (1), obtain two consecutive frames of images including the same scene captured by the remote sensing satellite camera;

[0048] The remote sensing satellite camera is an area array camera. When the area array camera is turned on, you can select the area array high-frequency imaging mode and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com