Production method of modified hydroxyapatite for efficiently removing fluoride in water body

A technology of hydroxyapatite and fluoride, applied in chemical instruments and methods, water pollutants, and other chemical processes, can solve the problem of low adsorption capacity, achieve scientific preparation methods, good ability to remove fluoride, and raw materials Easy to get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] (1) to AlCl 3 Add Na to the solution 2 CO 3 , the preparation of polyaluminium chloride with a degree of alkalization of 2.0;

[0021] (2) Utilize the polyaluminum chloride prepared in step (1) to prepare the required nanometer Al 13 solution;

[0022] (3) Weigh a hydroxyapatite sample of a certain quality, and disperse it uniformly in absolute ethanol to prepare a hydroxyapatite suspension;

[0023] (4) the nano-Al prepared by step (2) 13 Add dropwise to the hydroxyapatite suspension prepared in step (3), react at a temperature of 25° C. for 1.0 h, and age for 12.0 h. After aging, suction filter, wash, and dry at 80° C. The modified hydroxyapatite is obtained after grinding.

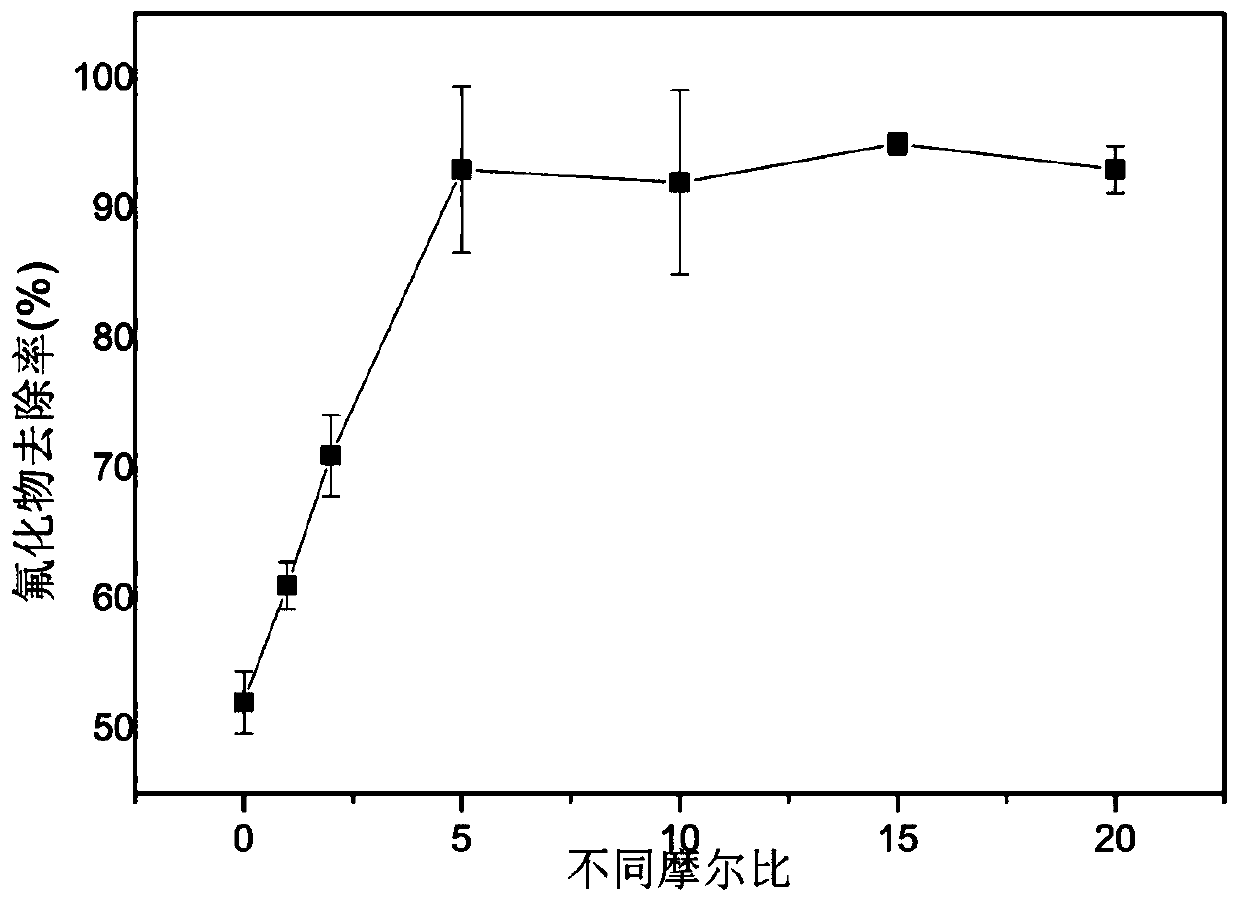

[0024] As shown in Figure 1, the initial fluoride is 10 mg / L, the volume is 50 ml, the mass of hydroxyapatite is 0.05 g, the adsorption time is 12 h, and the adsorption temperature is 25 °C; When the ratio increases, the fluoride removal rate is significantly improved. When the molar mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| adsorption temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com