Intelligent pilot-operated automatic embolism, high-efficiency air-saving, anti-blocking and anti-wear control system

A control system and pilot-operated technology, which is applied in the direction of conveyors, transportation and packaging, and conveying bulk materials, can solve the problems of shortened service time of valves, high number of valve actions, complex system configuration, etc., and achieve improved conveying efficiency and long service life. Long, high delivery concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

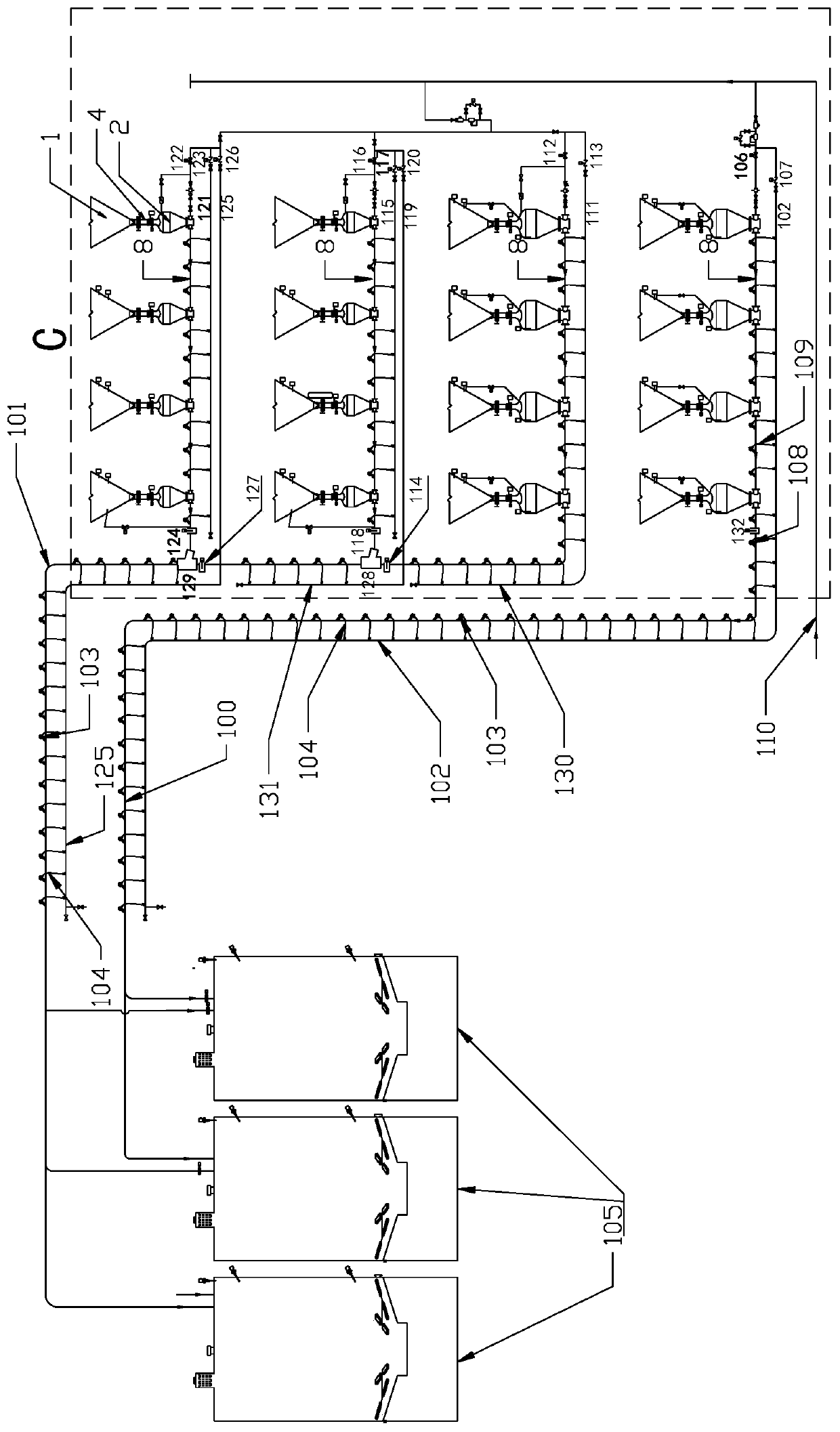

[0027] Such as figure 1 and Figure 5As shown, in the intelligent pilot-operated automatic embolism high-efficiency gas-saving, plugging and anti-wear control system of this embodiment, each furnace in the power plant is only provided with two main ash conveying pipelines leading to the ash store 105; The coal container is the first conveying unit, which uses the first main ash conveying pipeline 100 to convey ash to the ash storehouse 105; the remaining electric fields are combined into the second conveying unit, and uses the second main ash conveying pipeline 101 to convey ash to the ash storehouse 105; The directions of the main ash conveying pipeline 100 and the second main ash conveying pipeline 101 are respectively provided with pilot ash conveying accompanying air pipes, the first main ash conveying pipeline 100 and the second main ash conveying pipeline 101 are respectively equipped with a first plug valve 103, the second The air inlet of a plug valve 103 is in fluid ...

Embodiment 2

[0175] In this embodiment, on the basis of the first embodiment, the exhaust pipeline of the bin pump 2 and the feeding pipeline of the bin pump between the ash hopper and the bin pump are upgraded.

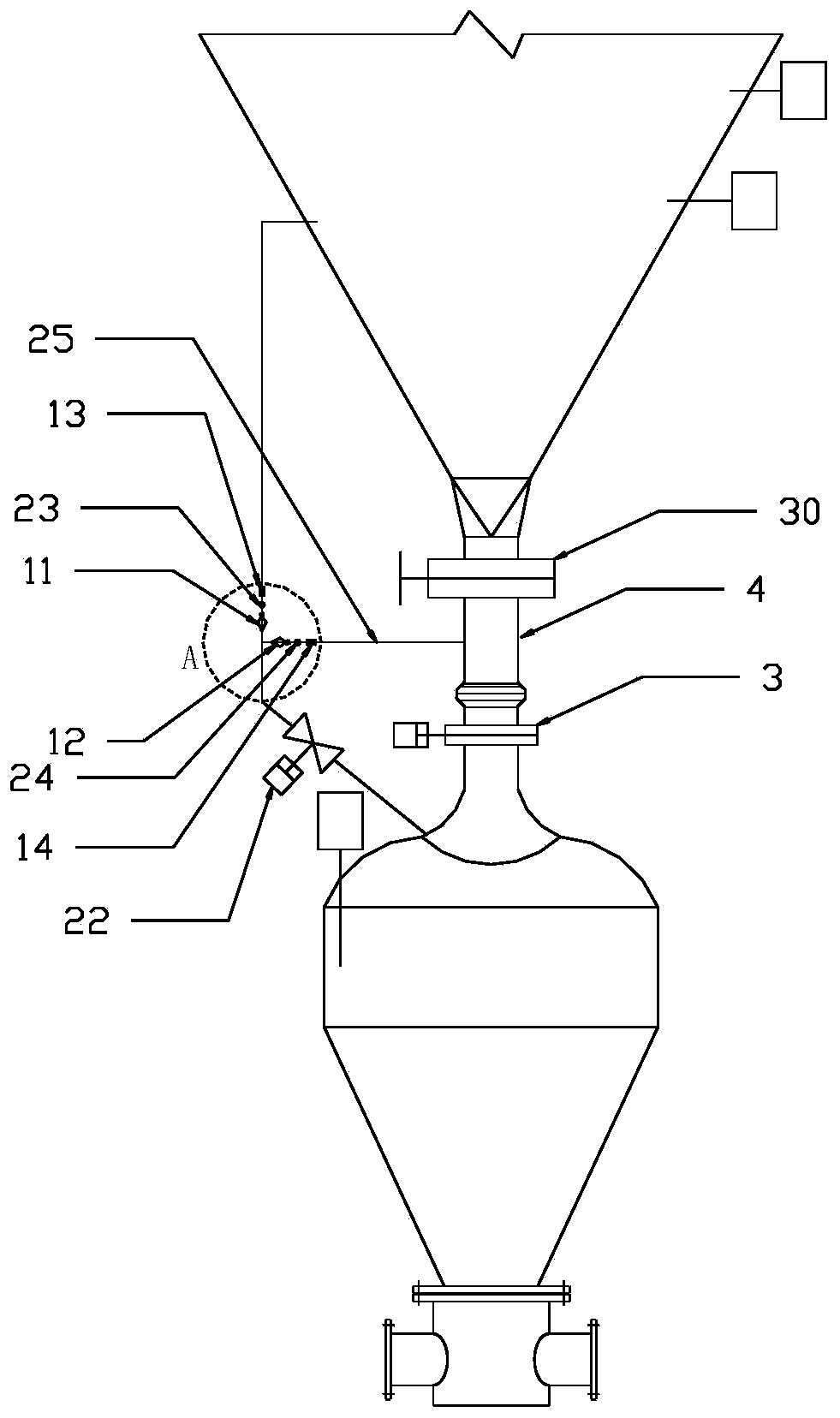

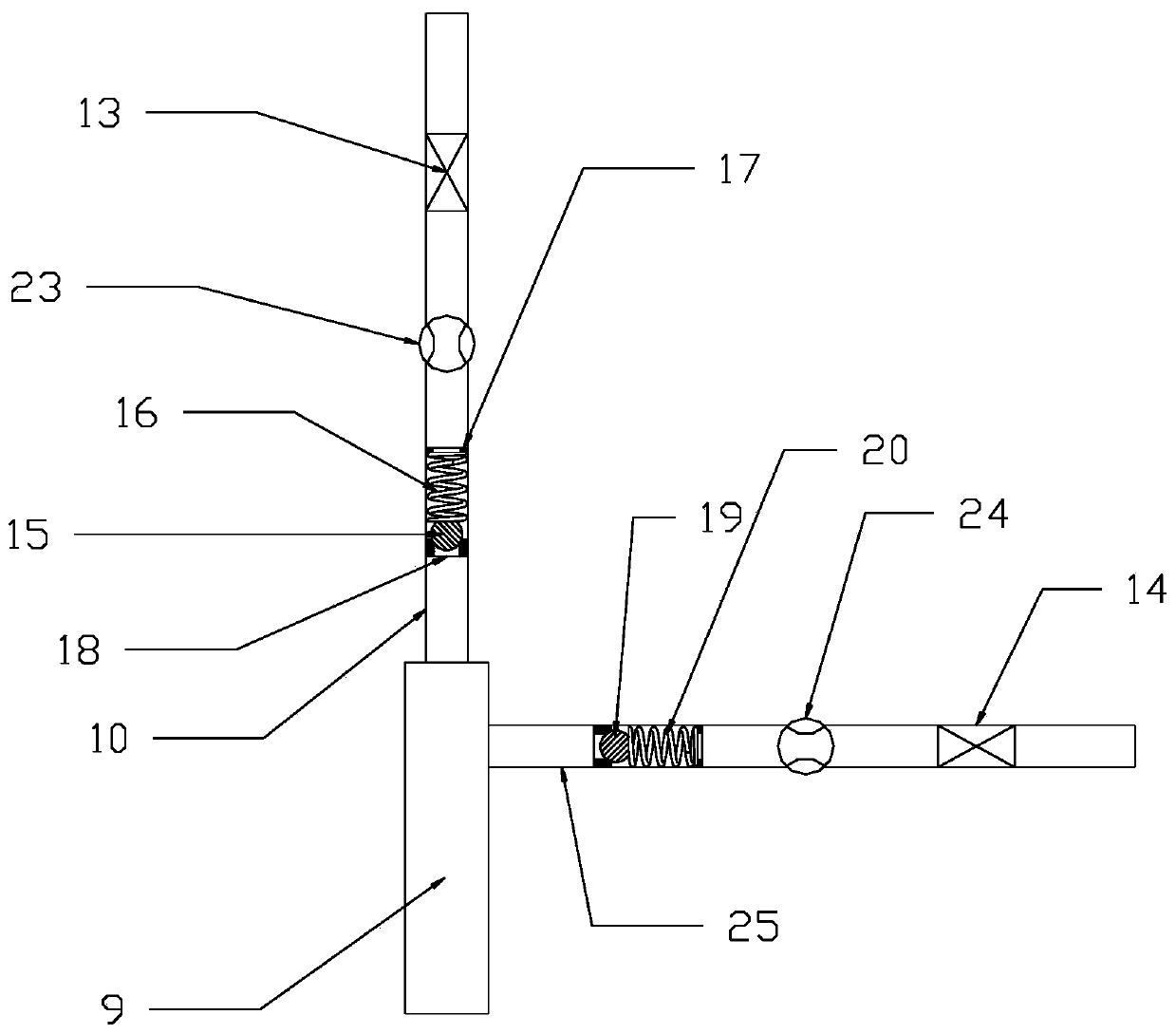

[0176] Such as Figure 2 to Figure 4 As shown, the maintenance valve 30 is installed on the discharge port of the ash hopper 1, and is connected to the feed port of the warehouse pump 2 through the feed pipeline 4 of the warehouse pump and the inlet dome valve 3 in sequence, The exhaust port of the warehouse pump 2 is in fluid communication with the intake end of the first exhaust pipeline 10 and the intake end of the second exhaust pipeline 25 respectively through the exhaust main pipe 9, and the first exhaust pipe The gas outlet of the road 10 is connected to the feed port of the ash hopper 1, and the gas outlet of the second exhaust pipeline 25 is connected to the warehouse pump feed pipeline 4; the first exhaust pipeline 10 is equipped with a first one-way valve 11 and a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com