Small-flux gas supply circular stirring anaerobic reaction method and reactor

An anaerobic reactor and circulating stirring technology, which is applied in the field of water treatment, can solve the problems of large gas flux and unresolved sludge properties, etc., and achieve the effect of improving removal effect and mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

application example 1

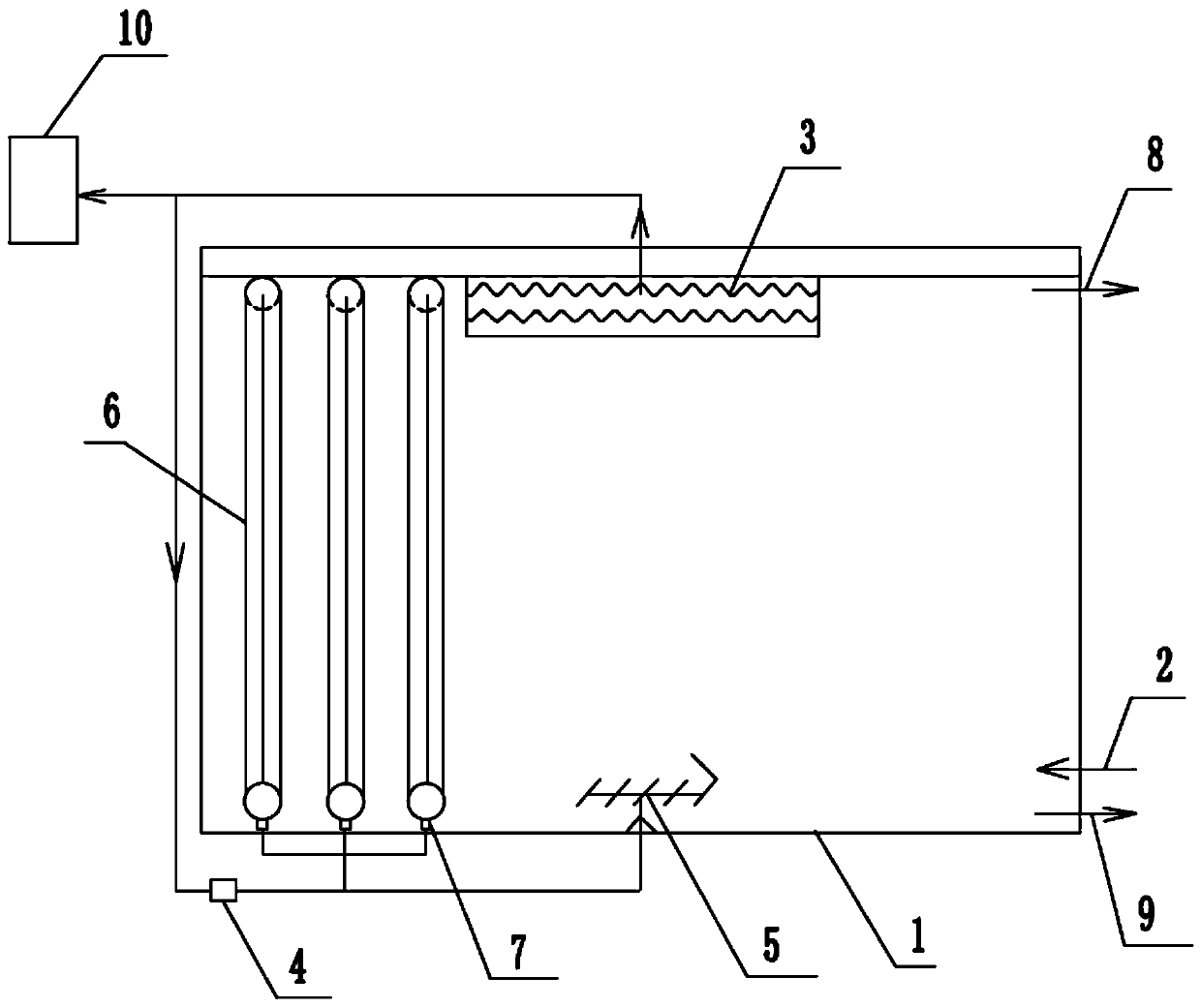

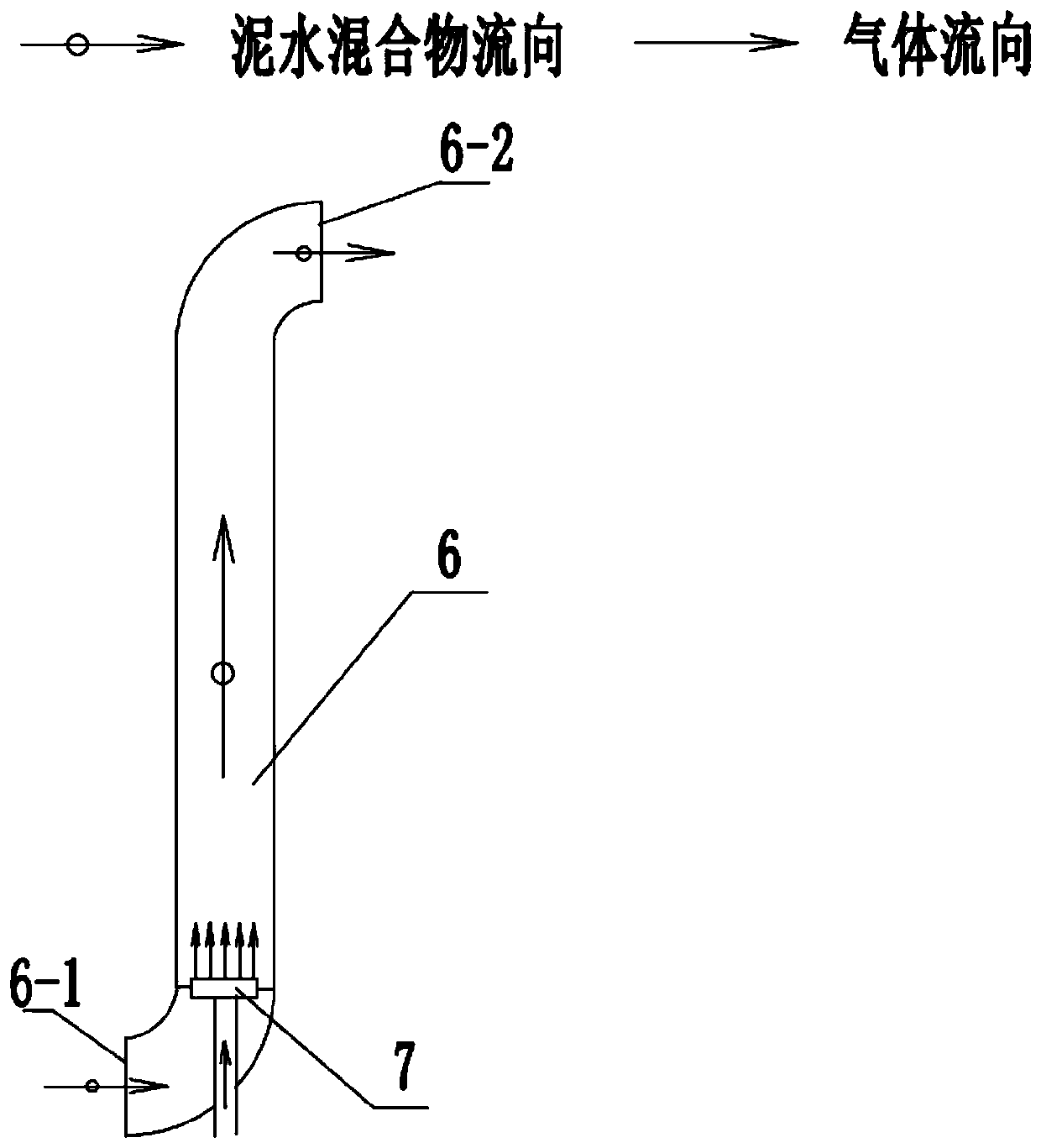

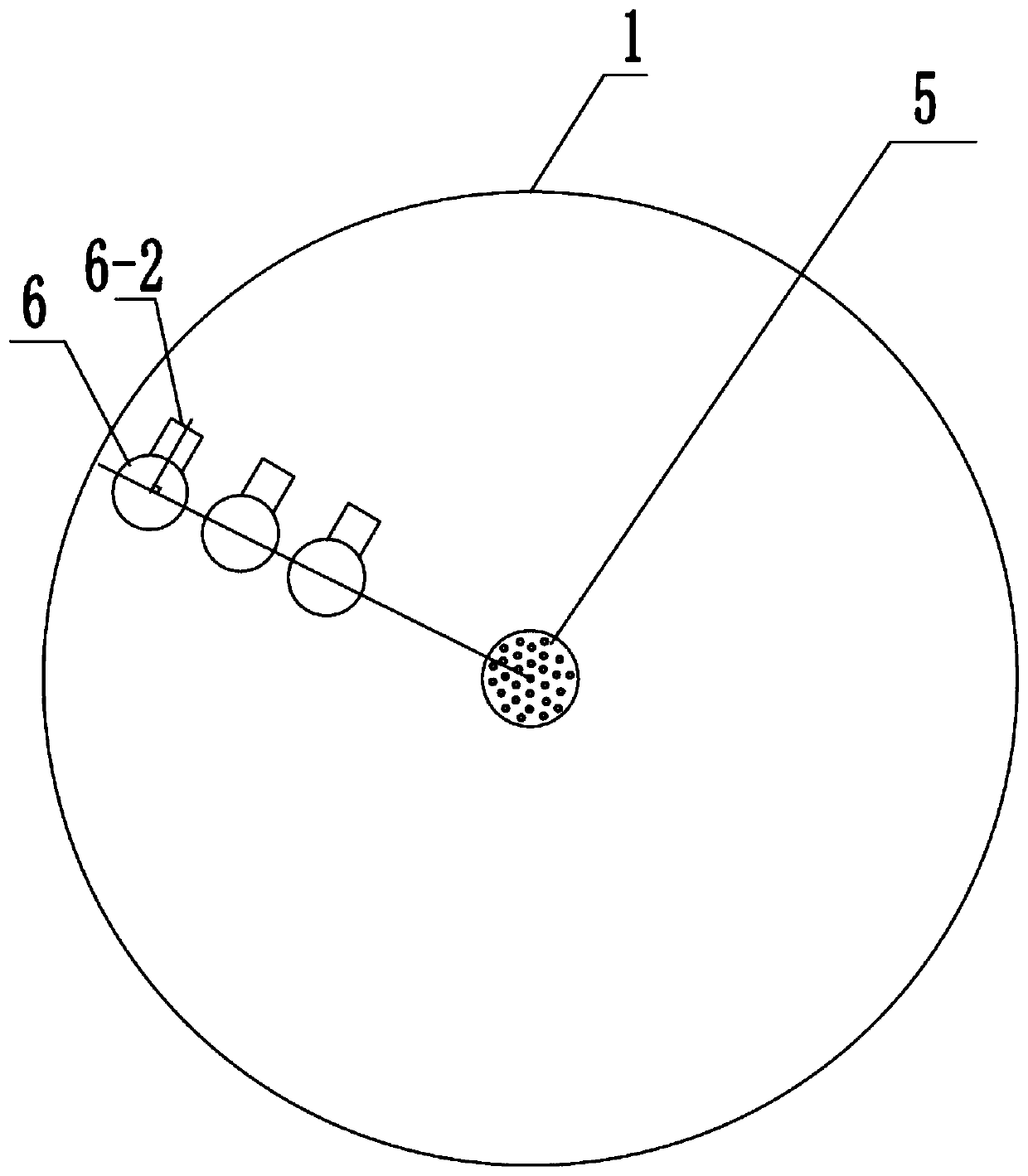

[0044] A small kitchen recycling device collects kitchen waste and kitchen waste from a community, about 8 tons per day. The recycling device is equipped with a solid crushing and extrusion device. The extruded liquid after extrusion needs to be treated on site and cannot be discharged directly. Squeeze liquid COD is 40000mg / L, design anaerobic reactor 100m of the present invention 3 A circular tank with a diameter of 6m and a height of 4.5m; three sets of airlift tubes of D100, distributed along the radial direction of the anaerobic reactor, close to the tank shell 1m, the distance between two adjacent sets of airlift tubes The diameter is 0.4m; the middle bottom of the anaerobic reactor is equipped with an aeration ring with a diameter of 300mm. This anaerobic reactor is used for the reaction, and about 20m of anaerobic sludge is added to the anaerobic reactor at startup. 3 , its water content is 80%, and it reaches a steady state after one month of operation. The effluent ...

application example 2

[0046] A pig farm with 30,000 pigs adopts the method of soaking manure in water, and produces a total of 300m of manure every day 3 , the manure is in the form of thin mud, with a solid content rate of 0.3%. It is necessary to use the anaerobic reactor of the present invention to degrade organic matter and produce biogas for power generation. Four anaerobic reactor tanks are designed, each with a diameter of 8m and a height of 5m. The semi-underground cement circular tank structure is adopted. Each tank is equipped with D400 central aeration plate and D200 airlift tube 3 groups. There is a biogas bladder on the top, equipped with a compressor. Biogas is produced every day and equipped with a generator, which can meet the electricity consumption of the pig farm. The effluent COD of the anaerobic reactor is less than 1000 mg / L, and it enters the downstream sewage plant for retreatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com