High-yield and energy-saving mixing type lime kiln

A lime kiln and mixing technology, applied in the field of lime production, can solve the problems of resource waste, increase fuel consumption, prolong calcination time, etc., and achieve the effects of improving production efficiency, avoiding resource waste and reducing fuel consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

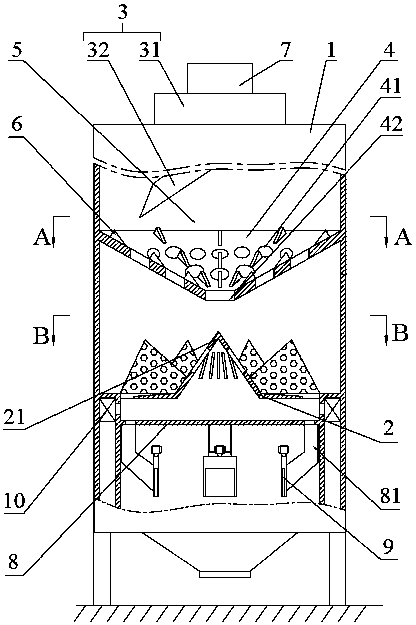

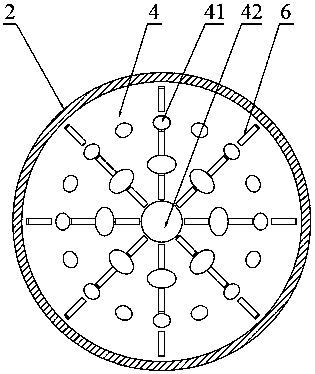

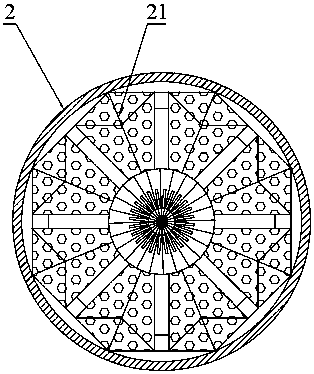

[0031] Such as Figure 1-3 As shown, the high-yield and energy-saving mixing type lime kiln includes a kiln body 1, a grate 2 is arranged inside the kiln body 1, a distribution mechanism 3 is arranged above the grate 2, and the distribution mechanism 3 and the grate 2 There is also a distribution plate 4 between them, and the distribution plate 4 is arranged obliquely. The lowest position of the inclined surface of the distribution plate 4 is set at the center of the distribution plate 4. In the kiln body 1, a large upper part and a smaller one are formed. The material distribution space 5 in the form of a hollow circular platform is provided with a number of through holes 41 for the passage of raw materials on the material distribution plate 4, and the through holes 41 gradually increase along the inclination direction of the material distribution plate 4.

[0032] In the high-yield and energy-saving mixing lime kiln of this embodiment, a material distribution plate 4 is arra...

Embodiment 2

[0039] Such as Figure 1-3 As shown, the structure of the high-yield and energy-saving mixing lime kiln of this embodiment is the same as that of Embodiment 1, the difference is that: the distribution plate 4 is also provided with a number of blocking blocks for blocking the movement of raw materials towards the discharge port 42 6.

[0040] In the high-yield and energy-saving mixing lime kiln of this embodiment, by setting the blocking block 6 on the material distribution plate 4, on the one hand, the moving speed of the raw material is slowed down, and the impact caused by the raw material falling into the grate 2 on the grate 2 is avoided, which affects the furnace. The stability of the raw materials laid on the grate 2, on the other hand, when the raw materials fall into the distribution plate 4, they are hit by the blocking block 6, and the volume is reduced, ensuring that the volume of the raw materials entering the grate 2 is relatively uniform, and further ensuring the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com