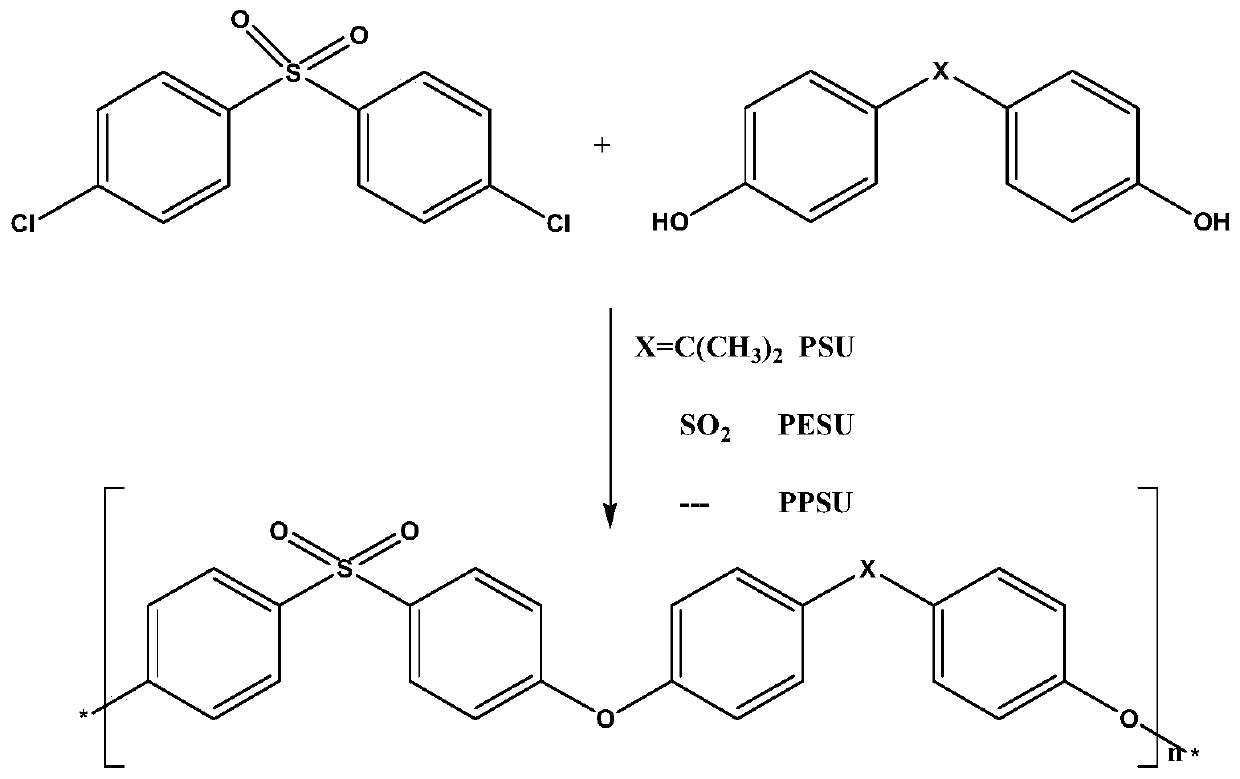

Preparation method for reducing cyclic dimer in polysulfone resin polymer material

A technology for polymer materials and cyclic dimers, which is applied in the field of preparation of cyclic dimers, can solve the problems of adverse effects on the product quality of polysulfone materials, affecting the storage and use of polysulfone materials, and being difficult to dissolve and remove, etc. The effect of reducing the influence of cyclic dimer impurities, the preparation method is simple and convenient, and the quality is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

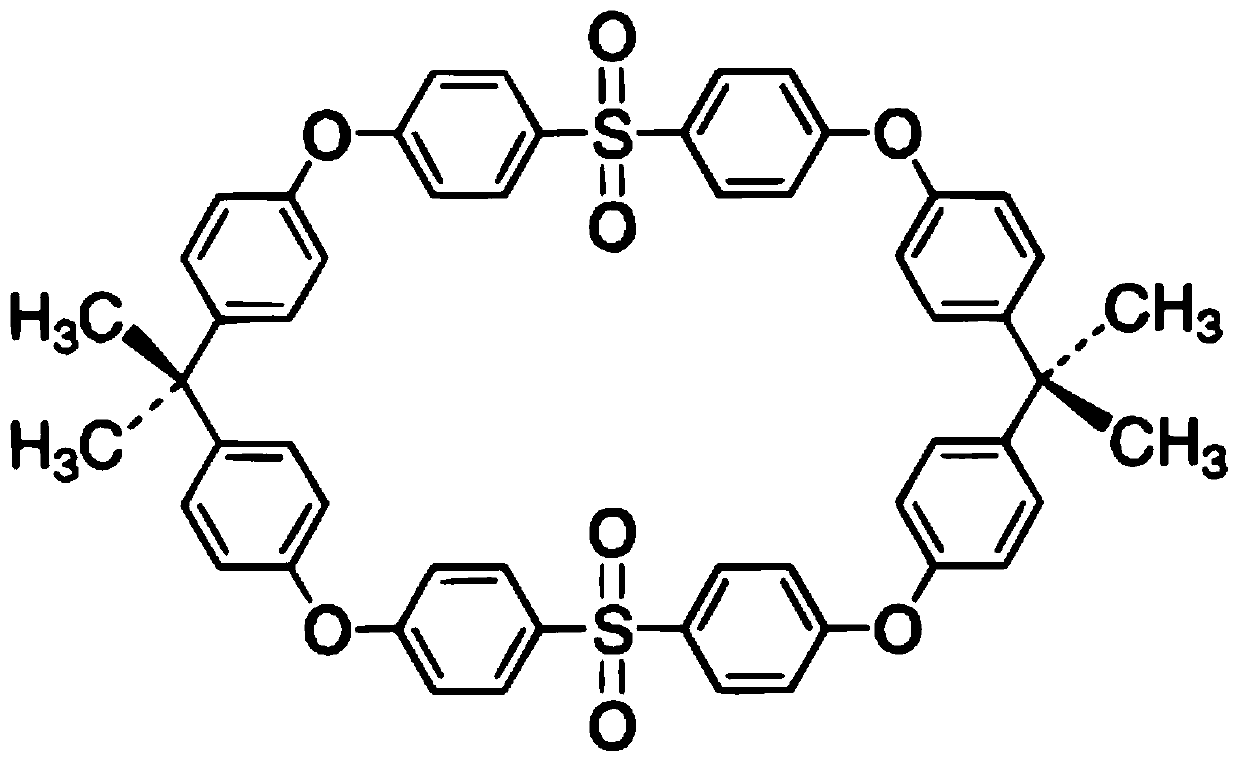

Problems solved by technology

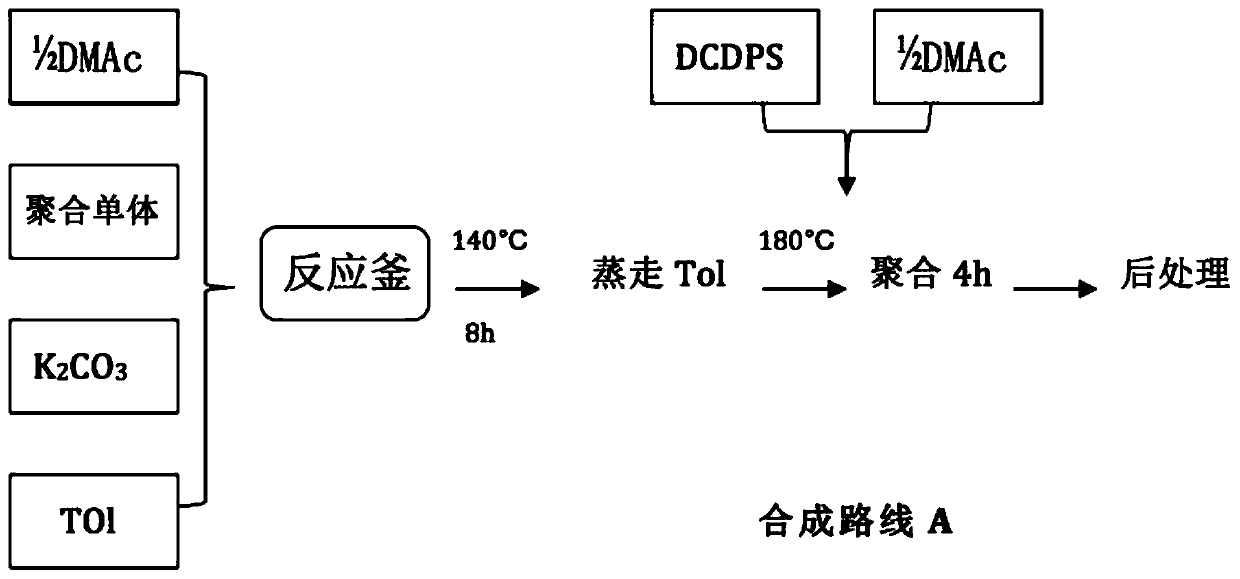

Method used

Image

Examples

Embodiment 1

[0029] 1) First, add 33.3kg DMAC into a 150L reactor, except for DCDPS, other materials bisphenol A BPA10kg, K 2 CO 3 11.5kg and 33.3kg of Tol were all added to the reaction kettle, water was separated for 8 hours at 140°C, Tol was evaporated, and the temperature was raised to 180°C. Dissolve 10kg of DCDPS in 33.3kg of DMAC, add dropwise to the reaction solution, complete the addition in 45 minutes, keep at 180°C for 4 hours for polymerization;

[0030] 2) Post-treatment: After the reaction is completed, cool to room temperature, settle into deionized water, wash 5 times at 80°C, and dry to obtain powdered bisphenol A polysulfone product (PSU);

[0031] 3) The obtained polysulfone product was tested for intrinsic viscosity by Ubbelohde viscometer and molecular weight distribution by GPC for gel permeation chromatography, and the content of cyclic dimer was determined to be 0.015 wt%.

Embodiment 2

[0033] 1) First, add 5kg DCDPS and 33.3kg DMAC into a 150L reactor, and the remaining materials bisphenol A BPA10kg, K 2 CO 3 11.5kg and 33.3kg of Tol were all added to the reaction kettle, water was separated for 8 hours at 140°C, Tol was evaporated, and the temperature was raised to 180°C. Dissolve 5kg DCDPS in 33.3L DMAC, add it dropwise to the reaction solution, complete the addition in 45 minutes, keep at 180°C for 4 hours for polymerization;

[0034] 2) Post-treatment: After the reaction is completed, cool to room temperature, settle into deionized water, wash 5 times at 80°C, and dry to obtain powdered bisphenol A polysulfone product (PSU);

[0035] 3) The obtained polysulfone product was tested for intrinsic viscosity with Ubbelohde viscometer and molecular weight distribution with gel permeation chromatography (GPC), and the content of cyclic dimer was determined to be 0.011 wt%.

Embodiment 3

[0037] 1) First, add 33.3kg DMAC into a 150L reactor, except for DCDPS, other materials include bisphenol S 10kg, K 2 CO 3 11.5kg and 33.3kg of Tol were all added to the reaction kettle, water was separated for 8 hours at 140°C, Tol was evaporated, and the temperature was raised to 180°C. Dissolve 10kg of DCDPS in 33.3kg of DMAC, add dropwise to the reaction solution, complete the addition in 45 minutes, keep at 180°C for 4 hours for polymerization;

[0038] 2) Post-treatment: After the reaction is completed, cool to room temperature, settle into deionized water, wash 5 times at 80°C, and dry to obtain powdery polyethersulfone product (PES);

[0039] 3) The intrinsic viscosity of the obtained polysulfone product was tested by Ubbelohde viscometer and the molecular weight distribution was tested by GPC by gel permeation chromatography, and the content of cyclic dimer was determined to be 0.019 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com